Off-axis three-reflector device

A three-mirror, third-mirror technology, applied in installation, optics, instruments, etc., can solve the problems of increasing the reflection performance of mirror deformation lenses, unable to adjust the mirror space position, affecting the performance of equipment, and avoiding local stress concentration. effect, avoid low precision, and reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

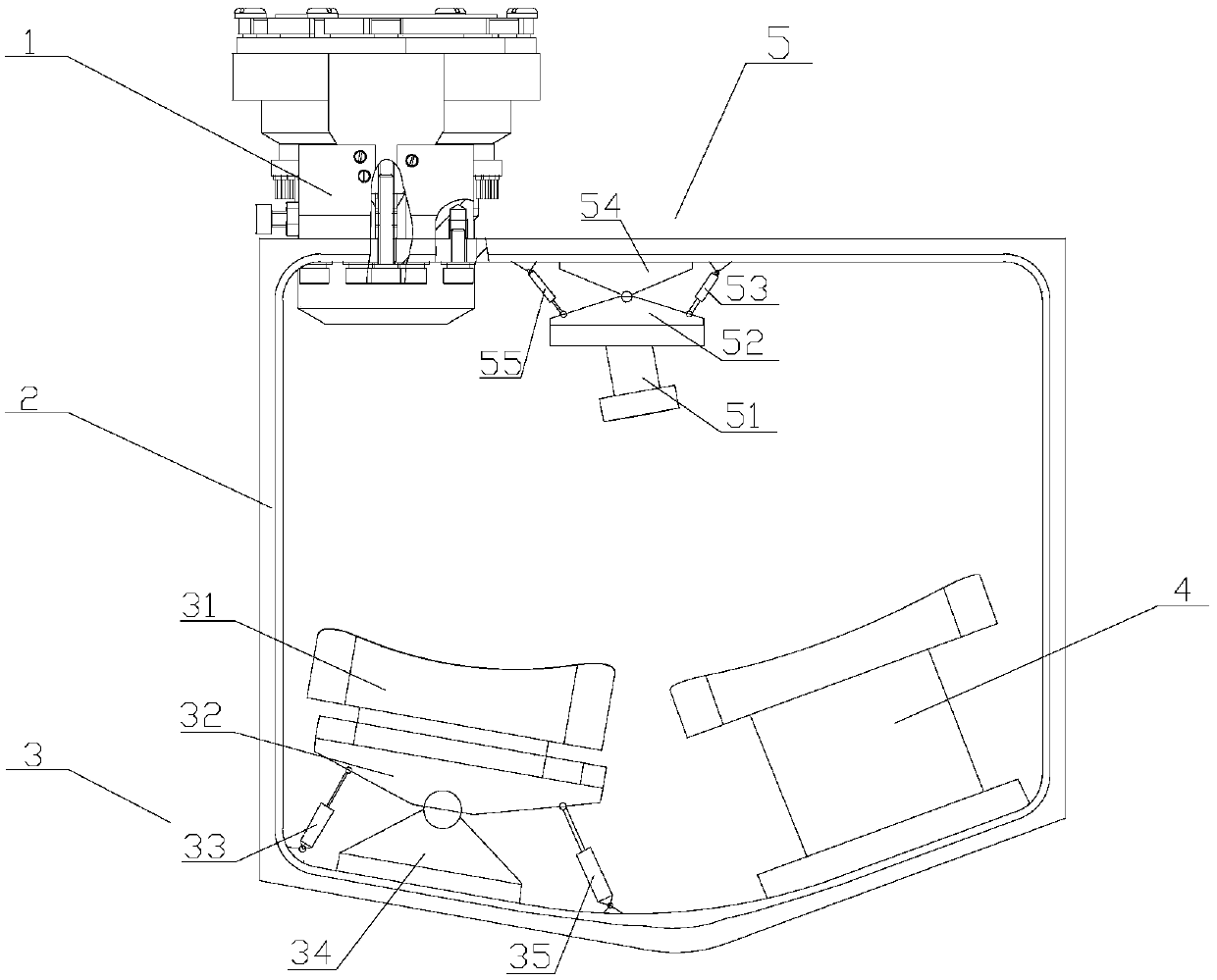

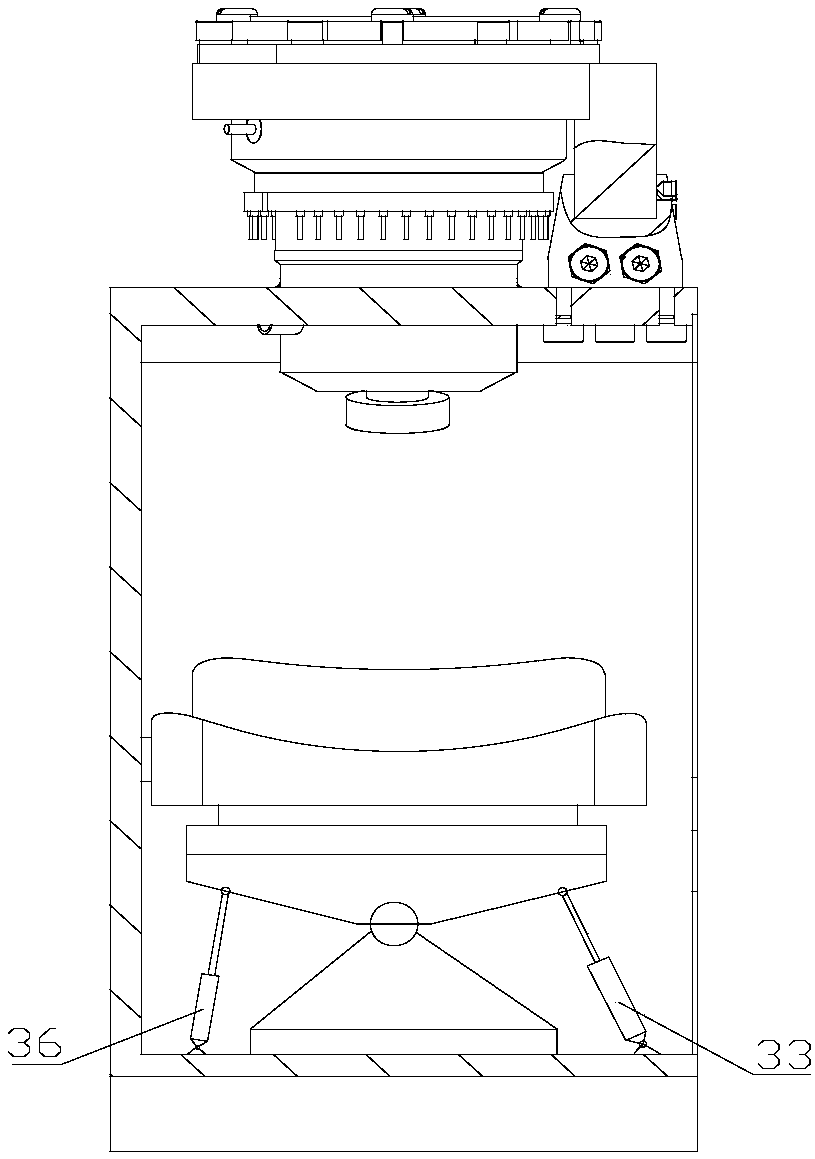

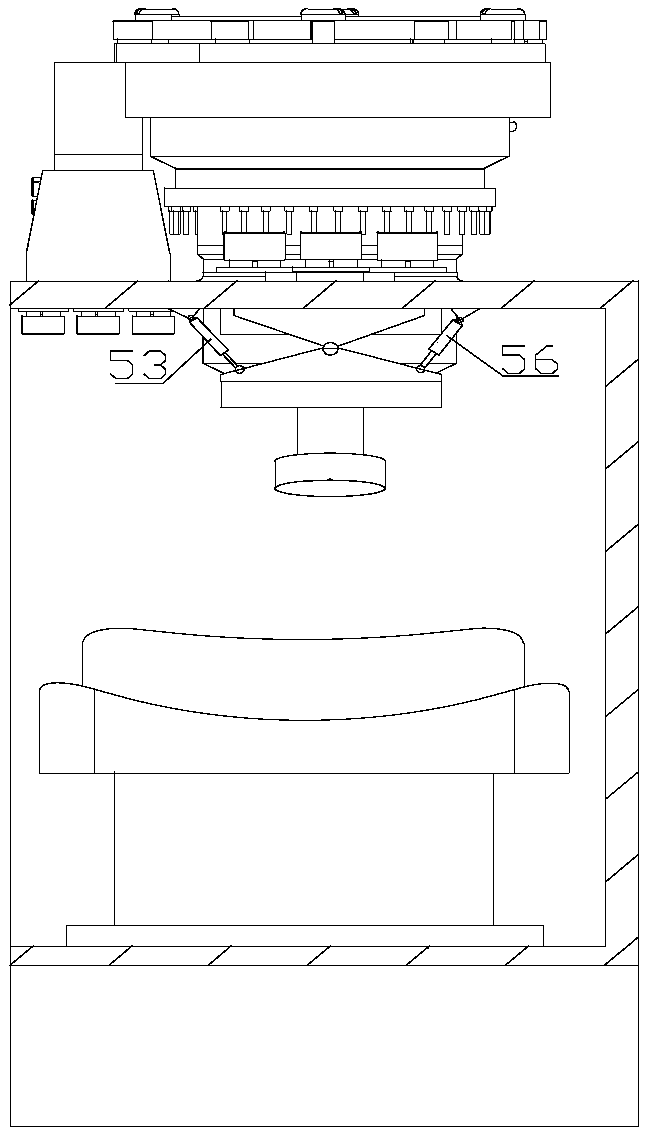

[0036] Such as Figure 1~3 As shown, an off-axis three-mirror device includes a first mirror assembly 3 , a second mirror assembly 5 , a third mirror 4 , a frame 2 and a detector assembly 1 . A cavity is provided in the frame 2, the second reflector assembly 5 is arranged at the top of the cavity, and the first reflector assembly 3 and the third reflector 4 are arranged at the bottom of the cavity. Specifically, in this embodiment, the bottom of the cavity is an inverted triangle shape composed of two slopes on both sides that slope downward toward the middle, and the first reflector assembly 3 and the third reflector 4 are respectively arranged on the two slopes. . The first reflector assembly 3 and the second reflector assembly 5 are oscillated by motor control, and the third reflector 4 is fixed.

[0037] Such as Figure 4 , 5 As shown, the detector assembly 1 is arranged on the top of the cavity and passes through the frame 2 . The detector assembly 1 includes a probe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com