Voice coil motor powered by electromagnetic induction

A voice coil motor, electromagnetic induction technology, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., to achieve the effect of reducing dynamic electromotive force, less motion obstruction, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

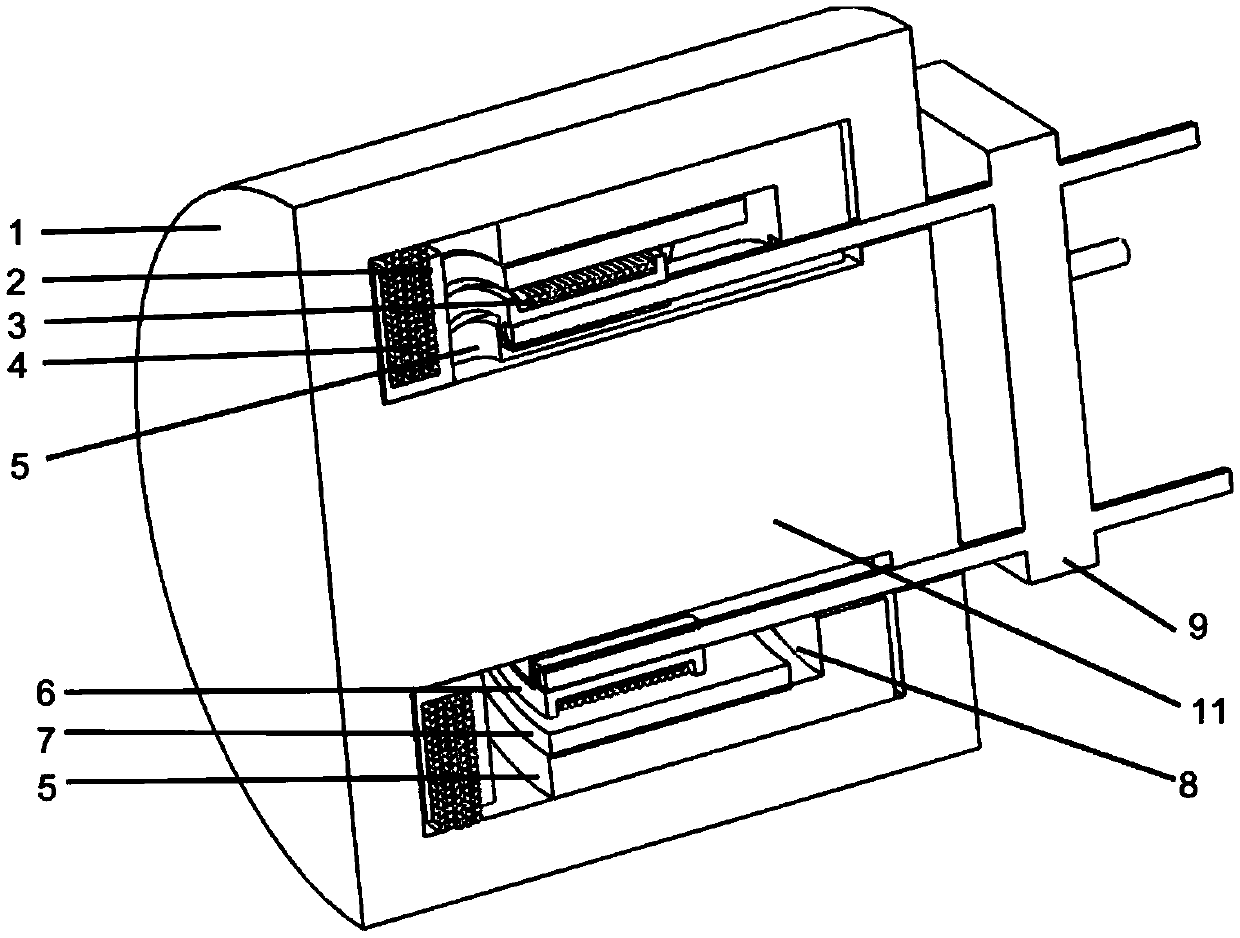

[0029] An alternative is a cylindrical voice coil motor such as figure 1 A cutaway view of a cylindrical voice coil motor is shown. The voice coil motor includes a moving coil 3, a high-frequency power supply coil 4, an annular permanent magnet 7, an annular magnetizer 5 and a magnetic core. The magnetic core is composed of a cylindrical magnetic core shell 1 and a cylindrical magnetic core column 11, the central axes of which coincide and the two ends are connected. The high-frequency power supply coil 4 and the moving coil 3 are coupled through the cylindrical magnetic core column 11, and a high-frequency excitation current is applied to the high-frequency power supply coil, and an induced current will be generated in the moving coil, thereby extending the magnetic core column under the action of the ampere force axial movement.

[0030] The annular magnetizer 5 is made of laminated silicon steel sheets, and an annular groove 8 is arranged on it, and the cylindrical magnet...

Embodiment 2

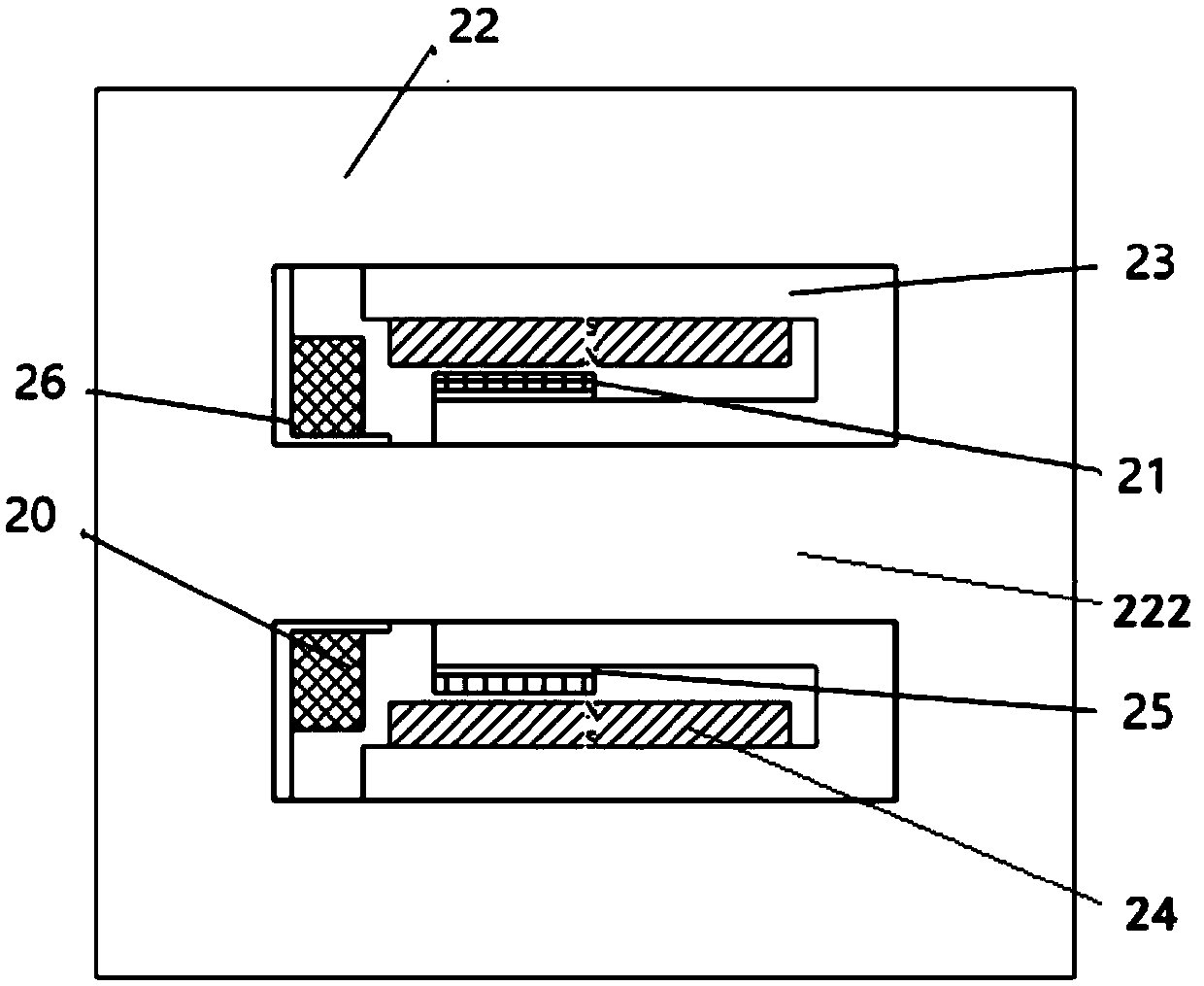

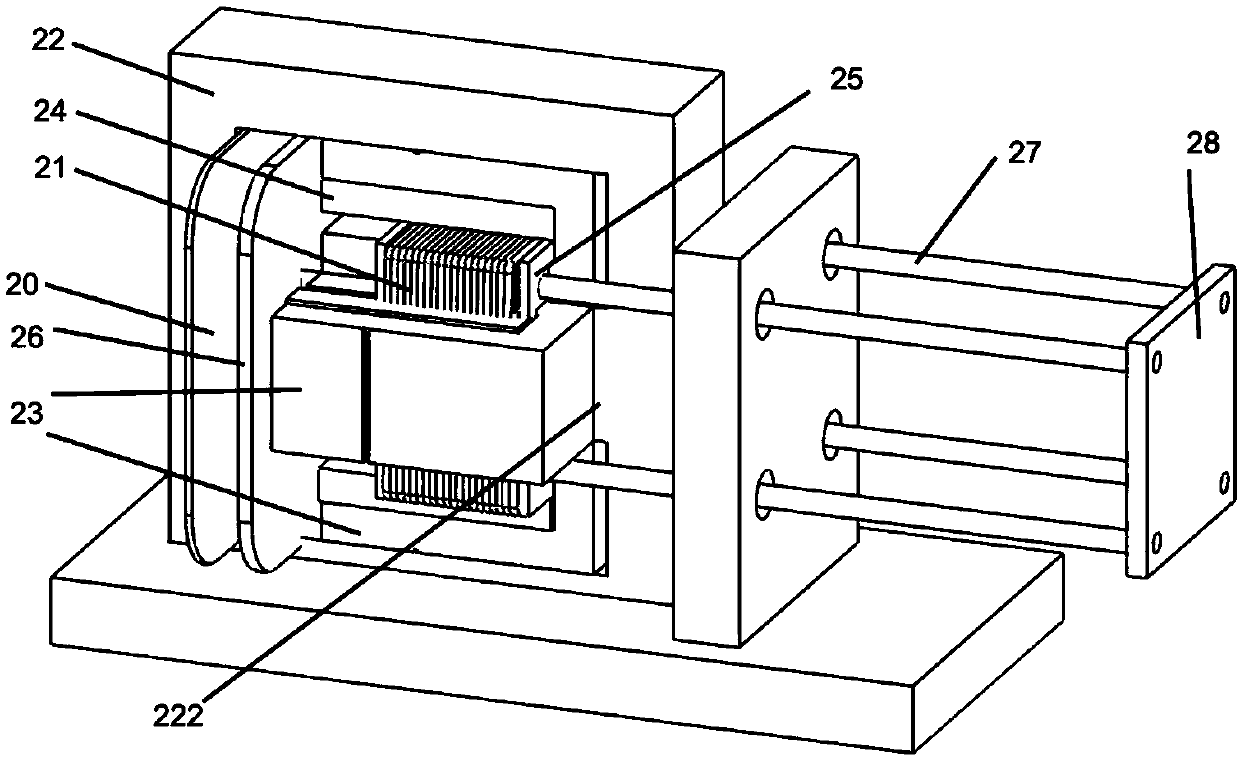

[0034] Another option is a rectangular voice coil motor, figure 2 and image 3 They are the sectional view and the complete perspective view of the main body of the motor respectively. It can be seen from the sectional view that the motor includes a moving coil 21 , a high-frequency power supply coil 20 , a bar-shaped permanent magnet 24 , a U-shaped magnetic conductor 23 and at least one set of EE-shaped magnetic cores 22 . The EE-type magnetic core 22 is composed of an EE shell and a core center column 222 , wherein the core center column 222 can be circular or square.

[0035]The U-shaped magnetic conductor 23 is made of laminated silicon steel sheets, and is arranged in the window of the EE-shaped magnetic core 22 . One side of the U-shaped magnetic conductor 23 is attached to the high-frequency magnetic core center column 222, and is driven by a 21-turn chain. The other side of the U-shaped magnetic conductor 23 is attached to the permanent magnet, and the outer surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com