Composite flavor tea rolling machine and rolling method

A kneading machine and tea technology, which is applied to the kneading machine and kneading field of compound fragrant tea, which can solve the problems of adding and so on, and achieve the effect of rich aroma, good pressing effect and strong compression ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

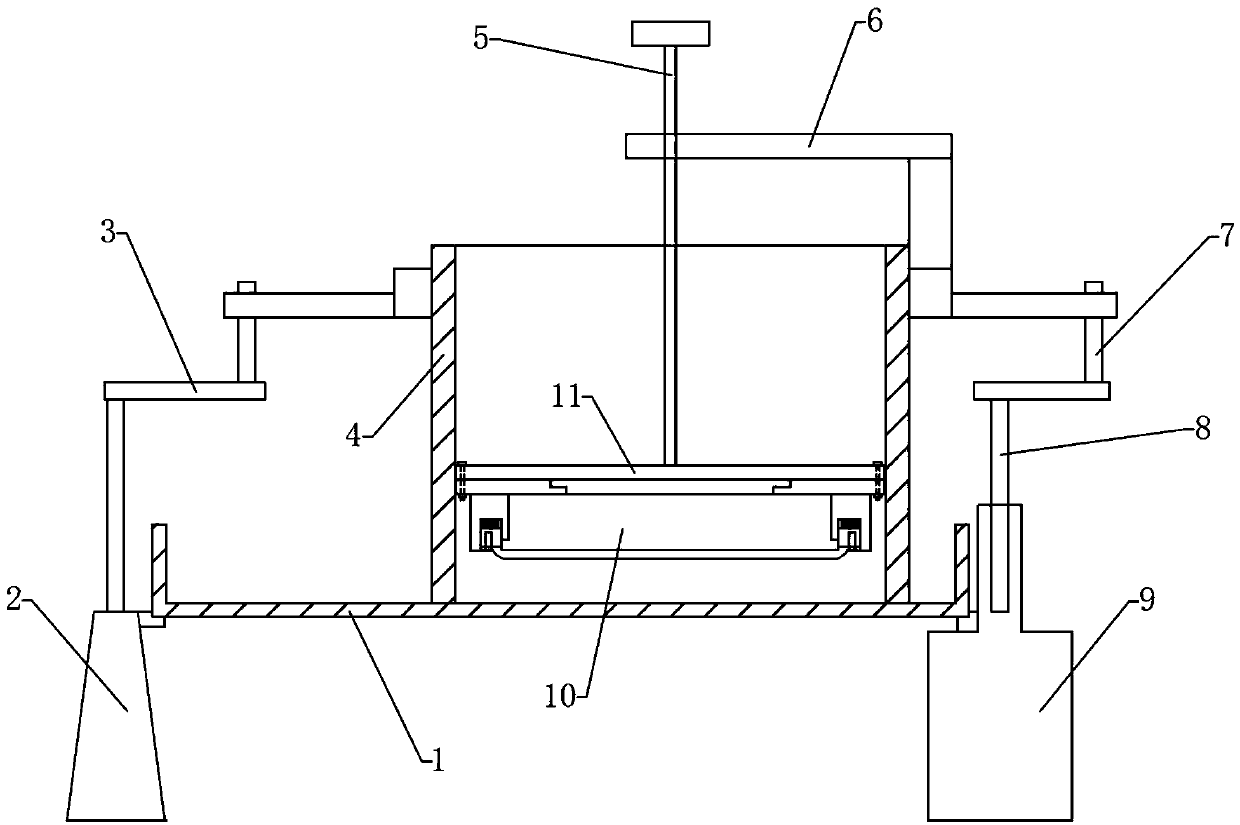

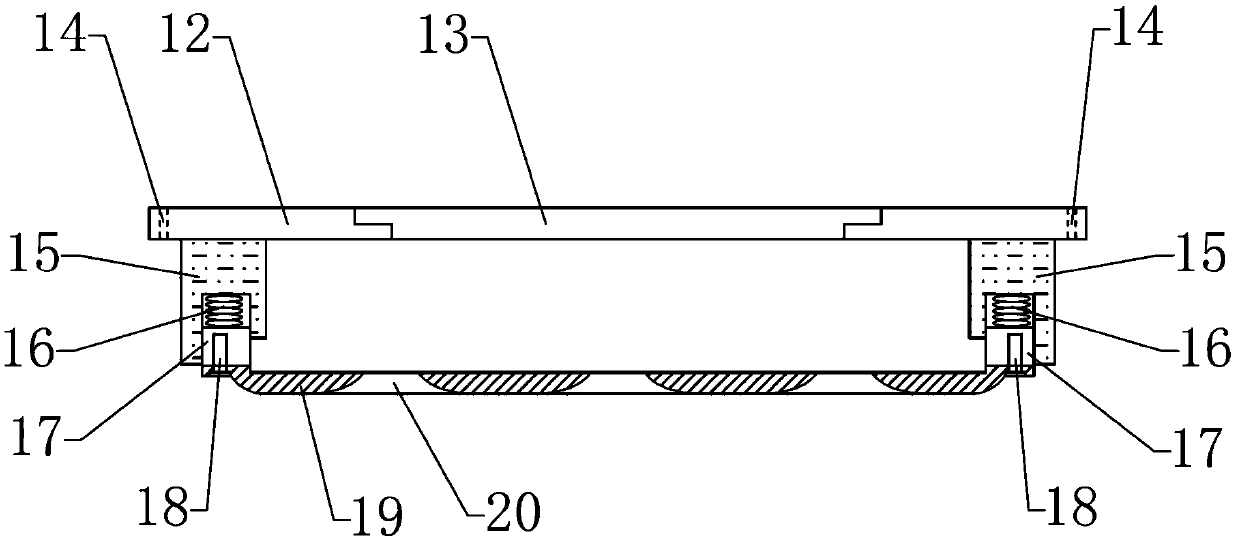

[0037] A kneading machine for compound fragrant tea, comprising a kneading disc 1, a motor 9 is arranged on the side of the kneading disc 1, an active rotating mechanism 7 is connected to the top of the motor 9 through a rotating shaft 8, and the active rotating mechanism 7 is connected to a kneading cylinder 4. The lower end of kneading cylinder 4 is as close as possible to kneading disc 1 upper surface, but does not contact. The kneading cylinder 4 is also connected with two passive rotation mechanisms 3, the lower end of the passive rotation mechanism 3 is connected with a fixed foot 2, and the fixed foot 2 is connected to the side of the kneading disc 1. The kneading cylinder 4 is provided with a cover plate 11, the cover plate 11 is connected with the fixed frame 6 through the height-adjustable fixed rod 5, and the fixed frame 6 is connected on the kneading cylinder 4. Above-mentioned structure is the same with kneading machine commonly used in the prior art.

[0038]In ...

Embodiment 2

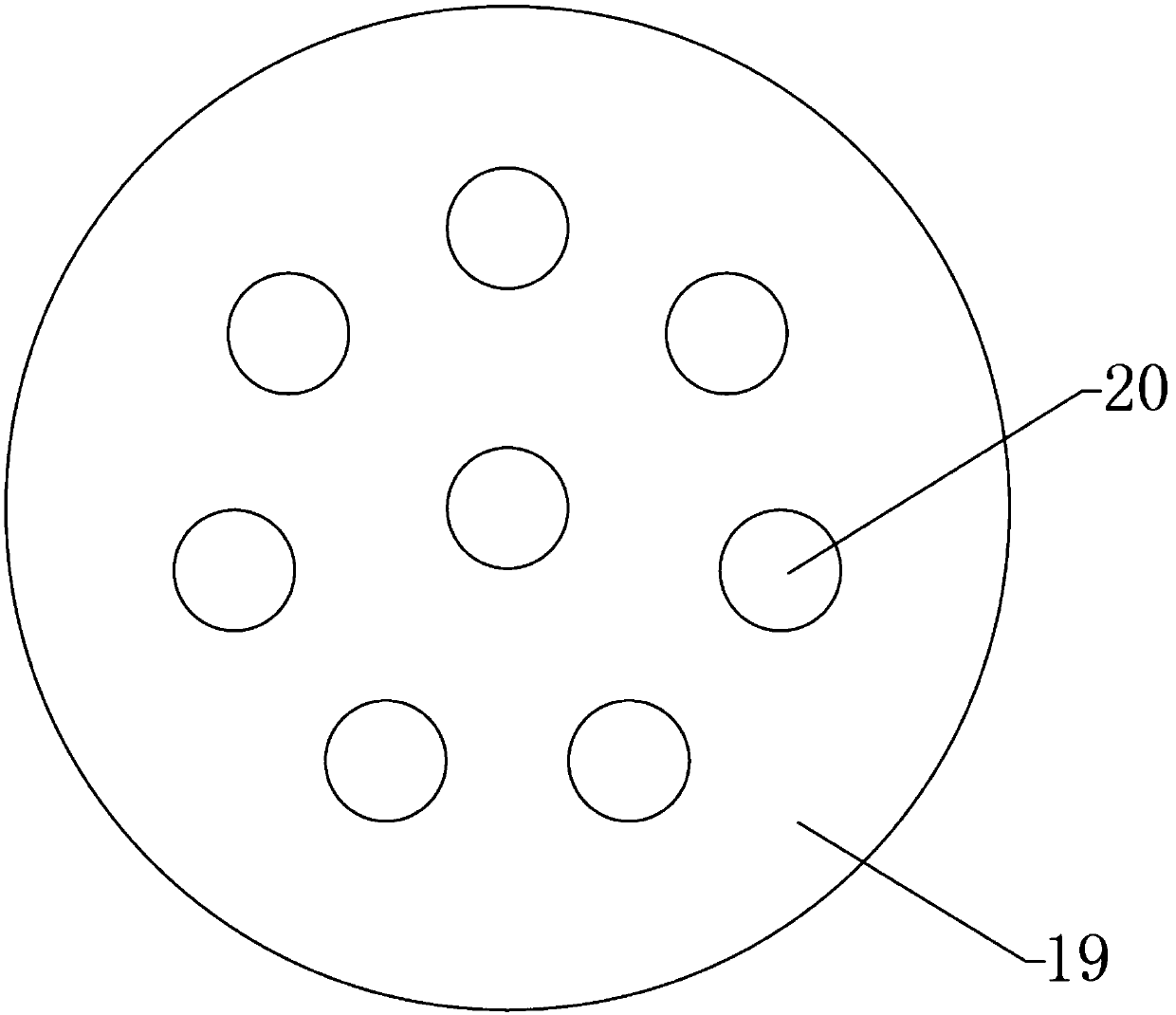

[0042] This embodiment is further preferred on the basis of Embodiment 1. The side of the kneading cylinder 4 is provided with a plurality of slots through, and a plurality of inserting plates 21 are arranged in the slots, and the inserting plates 21 are located in the inside of the kneading cylinder 4 Part of the edge of the base plate 19 is in contact with each other. In this way, the inserting plate 21 can block the edge of the bottom plate 19 and prevent the press box 10 from moving downward. Therefore, the inserting plate 21 has the function of limiting.

[0043] The preferred solution of this embodiment has the following two effects: first, by setting the slot and the inserting plate 21 at a reasonable height, the minimum height of the press box 10 can be limited, thereby limiting the amount of tea leaves loaded into the kneading cylinder 4. Second, the pressure on the bottom plate 19 can be increased by using the insert plate 21 to squeeze the bottom plate 19, so that ...

Embodiment 1 and Embodiment 2

[0044] The application method of embodiment 1 and embodiment 2 is as follows:

[0045] A method for rolling compound fragrant tea leaves, comprising the steps of:

[0046] [1] Pack other raw materials for producing complex aroma tightly into the pressing box 10 . The ingredients used for this step should be able to squeeze out the juice. For example, fruits, flowers and some juicy herbs can be used. If the raw material is not easy to produce juice, according to the type of raw material used, pretreatment can be carried out before other raw materials used to produce compound aroma are loaded into the press box. The pretreatment methods include soaking, heating, extrusion, and watering. At least one of wet or sliced. In addition, if the raw material is easily broken into fine particles, gauze can be used to sew a cloth bag, and the raw material is packed into the cloth bag and then packed into the press box 10.

[0047] [2] Put the tea leaves to be kneaded into the kneading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com