A canteen dish washing machine

A washing machine and dish washing machine technology, applied in the direction of washing machine/rinsing machine for tableware, parts of washing machine/rinsing and washing machine for tableware, cleaning device, etc., which can solve the problems of complex structure and high price of tableware washing machine, and achieve simple structure , low cost and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

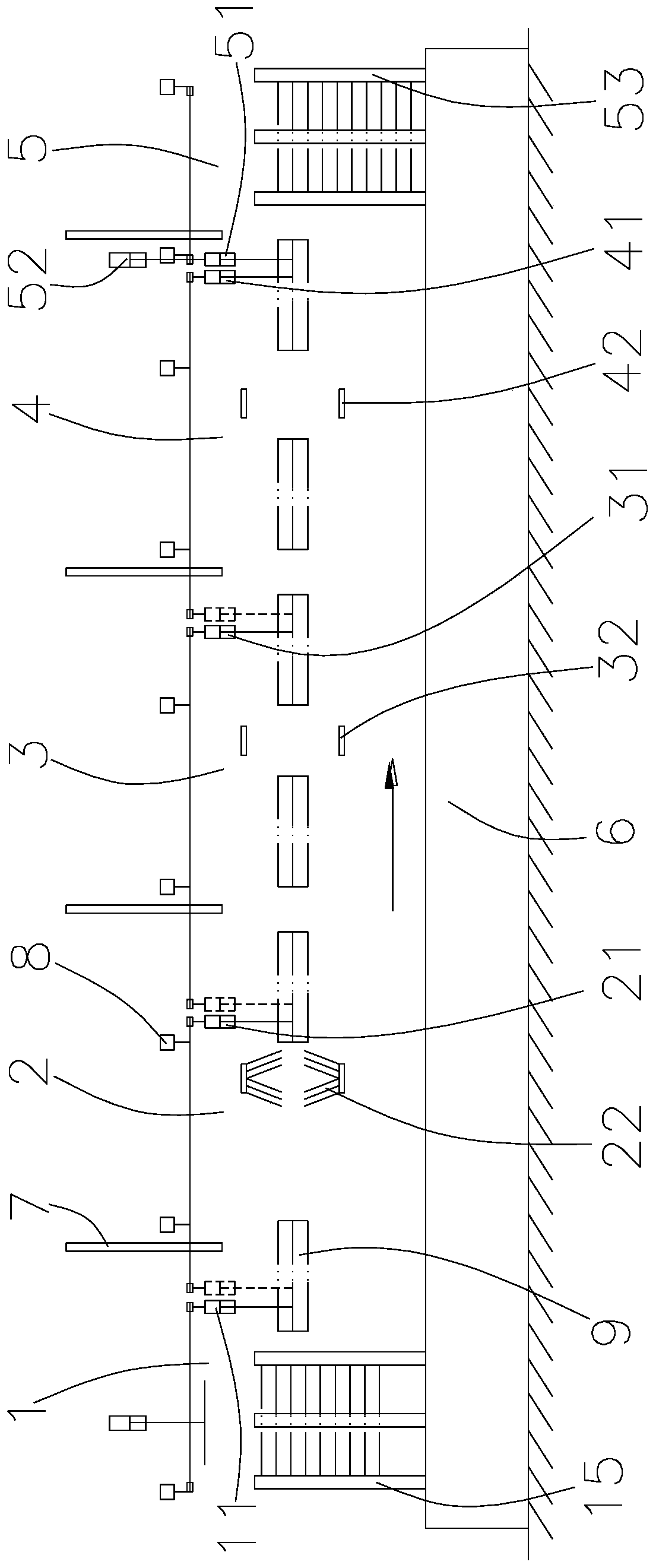

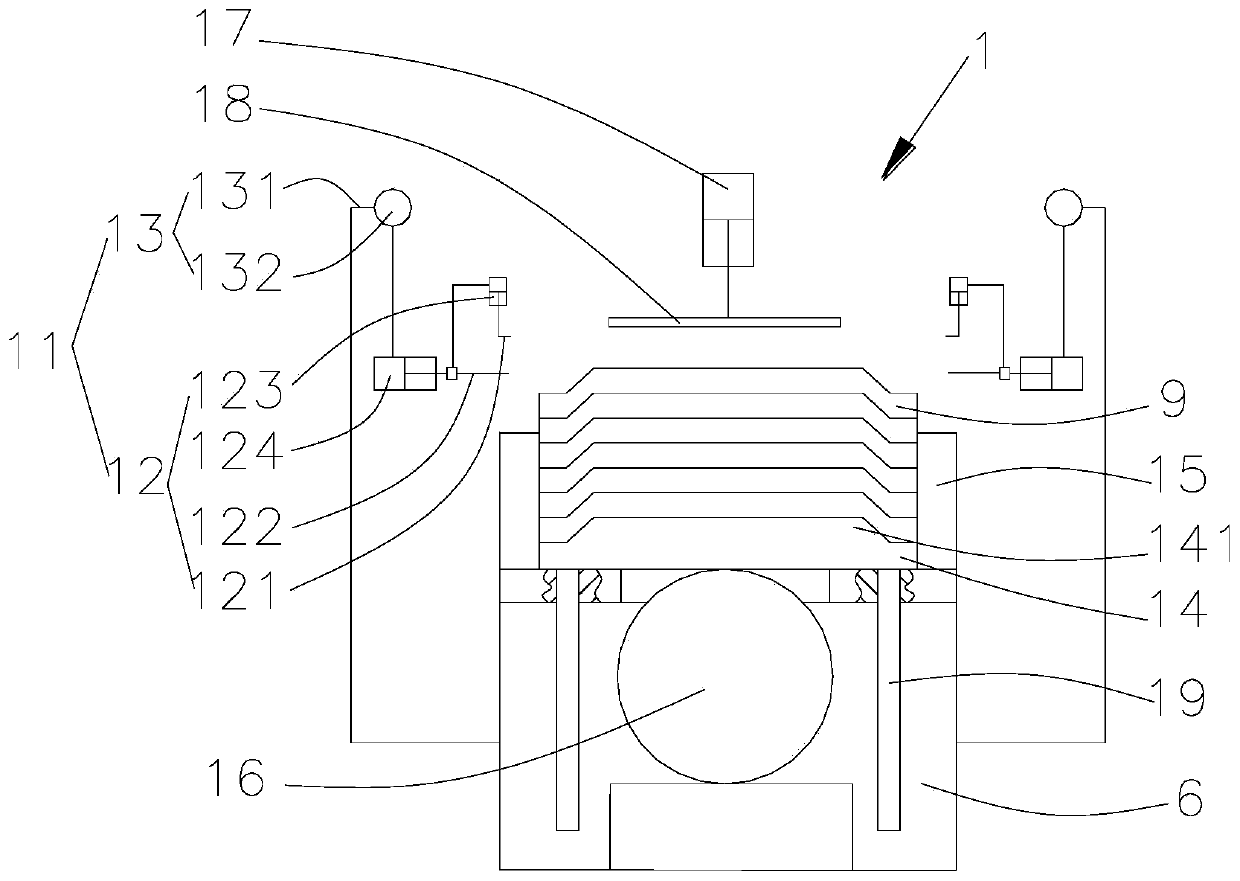

[0033] Such as Figure 1~6 As shown, a canteen dish washing machine includes a workbench 6 and a clamping mechanism, and the workbench 6 is sequentially provided with a separation station 1, a brushing station 2, a rinsing station 3, a drying station 4 and The finishing station 5 also forms a cleaning line; the clamping mechanism includes a jaw assembly 12 and a drive assembly 13, the jaw assembly 12 is used to clamp the dinner plate 9, and the drive assembly 13 drives the jaw assembly 12 along the cleaning assembly line movement;

[0034] Such as figure 2 As shown, the separation station 1 includes a first limiting plate 15 detachably arranged on the workbench 6 and a support plate 14 slidingly arranged on the workbench 6 up and down, and the first limit plate 15 is arranged along the support plate 14, the circumferential distribution of the support plate 14 is provided with an airbag 16, when the airbag 16 is inflated, it pushes the support plate 14 to move upward, and a ...

Embodiment 2

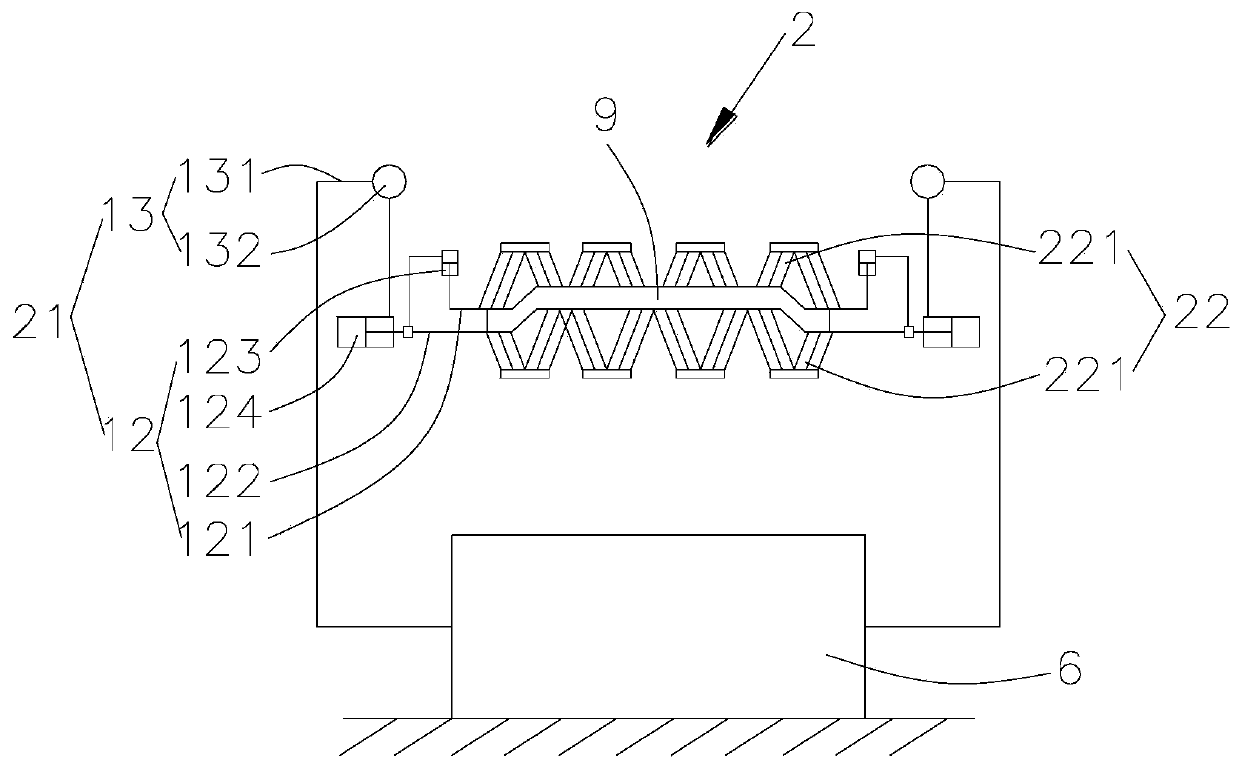

[0050] Such as Figure 7 As shown, in this embodiment, the difference from Embodiment 1 is that two brushing stations 2 and two flushing stations 3 are arranged along the cleaning line, and the two brushing stations 2 Adjacent to one another, the two flushing stations 3 are adjacent to one another.

[0051] The working principle is the same as in Embodiment 1, the transfer of the dinner plate 9 between the two scrubbing stations 2, and the transfer of the dinner tray 9 between the two washing stations 3, and the transfer of the dinner tray 9 between the scrubbing station 2 and the rinsing station 3 9's transfer works the same. Two scrubbing stations 2 and two rinsing stations 3 are set to improve the cleaning degree of the canteen dish washing machine, which is more clean and hygienic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com