Partitioned sticking and bonding method of large-scale metal or composite shell plate and industrial rubber

A composite material, large-scale technology, used in metal processing and other directions, can solve the problems of low connection strength, poor bonding performance, peeling of the cover, etc., to improve the quality and strength of interface bonding, improve interface bonding strength, reduce The effect of interfacial porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The invention will be described in detail below in conjunction with specific embodiments.

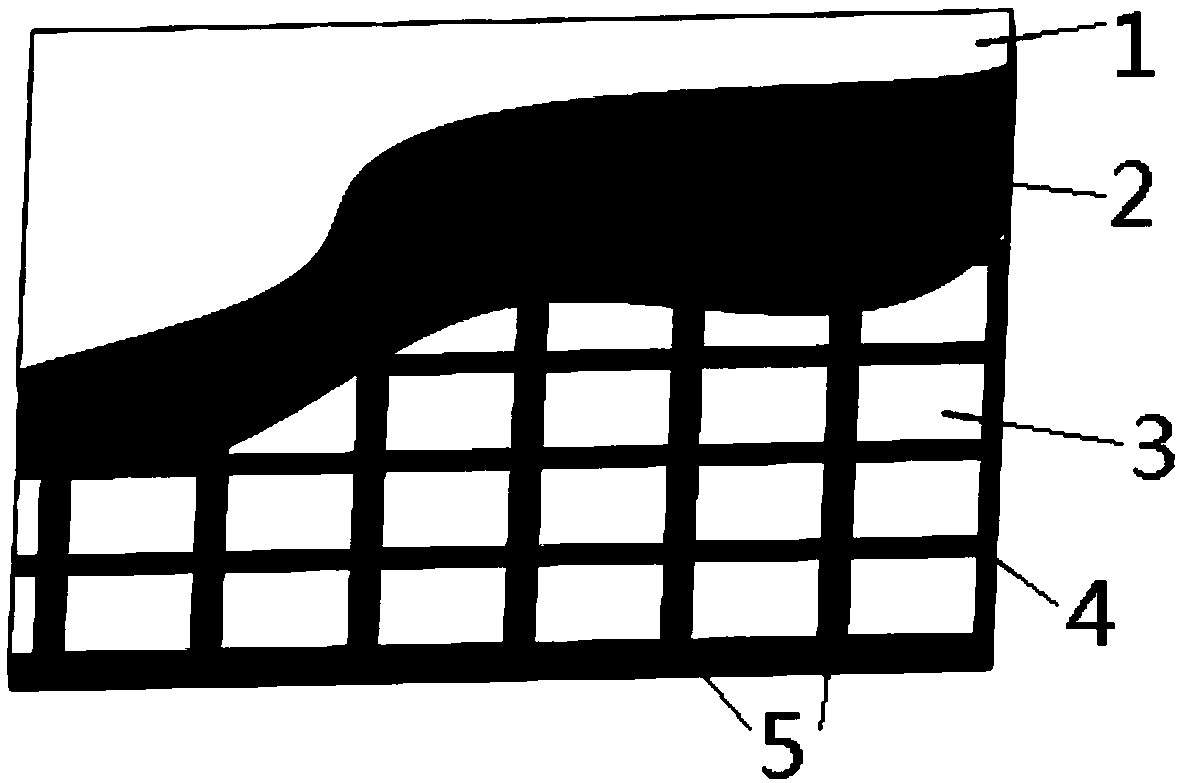

[0029] Such as figure 1 As shown, the present invention is used to bond a large-scale metal or composite material shell plate with curvature and a rubber plate into a unified whole, and its specific steps include:

[0030] Step 1. Prepare a single-sided FRP rubber plate 3 that has a regular shape and can fit each other. The single-sided FRP rubber plate 3 is made by vulcanizing a 0.2-0.8mm thick FRP sheet on one side of the rubber plate. The thickness of the single-sided FRP rubber plate 3 15-25mm, and the hardness of the resin used for forming the FRP sheet should be equivalent to that of rubber;

[0031] Step 2. Bonding groove treatment, specifically refers to opening uniform bonding grooves on one side of the vulcanized FRP surface of the rubber sheet, the bonding groove spacing A is 40-100mm; the bonding groove width B is 2-5mm; the bonding groove width B is 2-5mm; The groo...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, the difference is:

[0041] (1) The shell plate of the structure is a metal curved plate, and the material is 45# steel;

[0042] (2) Groove one side of the single-sided FRP rubber plate, the groove spacing is 40mm, the groove width is 5mm, and the groove depth is 1mm. In the specific implementation process, the groove spacing is calculated through the following steps:

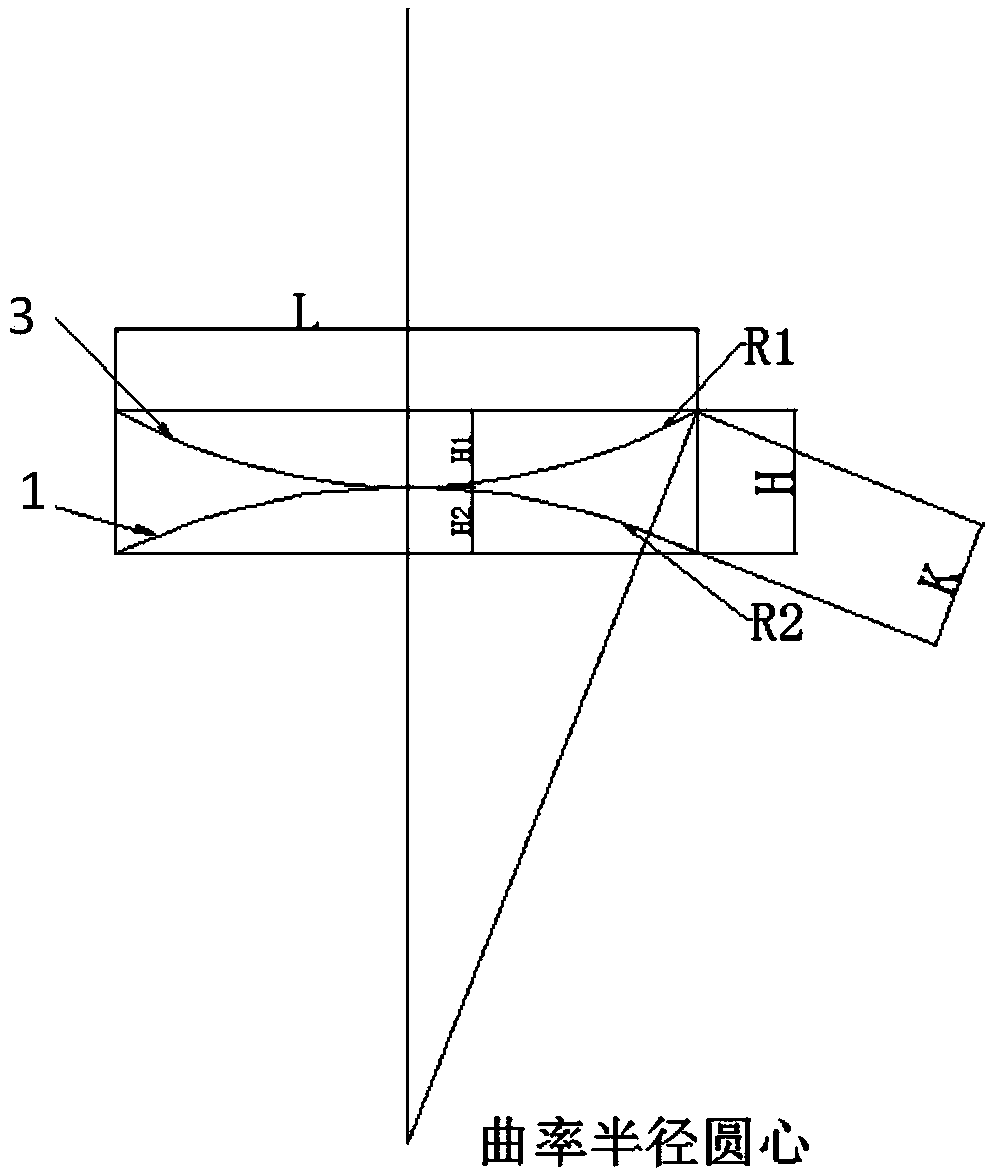

[0043] 2.1 Establish a local model, the surface profile of the shell plate has a local curvature radius of R 2 , the local radius of curvature of the rubber plate is R 1 , the accuracy of the surface fluctuation is K, the groove spacing is A, and other dimensions are shown in the figure, such as figure 2 shown.

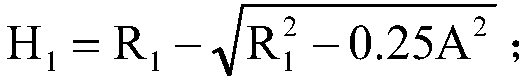

[0044] 2.2 According to figure 2 Calculate slot spacing as shown, and

[0045]

[0046]

[0047] Combining the above formulas, we get

[0048] The bending degree of each rubber vulcanized composite shell plate 1 is measured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com