Novel AUV (autonomous underwater vehicle) water-jet propeller

A water jet propulsion, a new type of technology, applied in the directions of underwater ships, underwater operation equipment, ships, etc., can solve the problems of use, and achieve the effect of improving pulsation, light weight and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

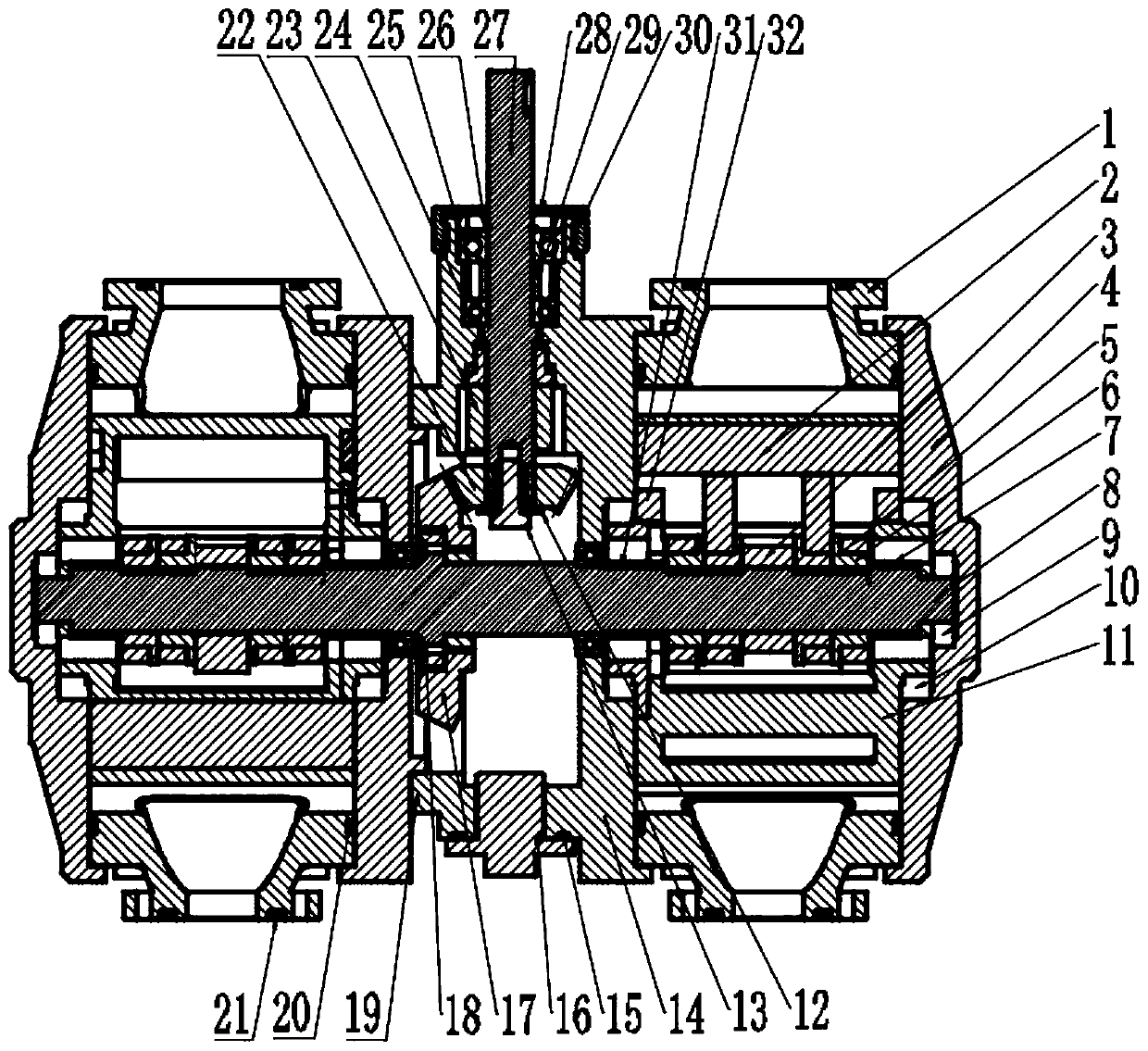

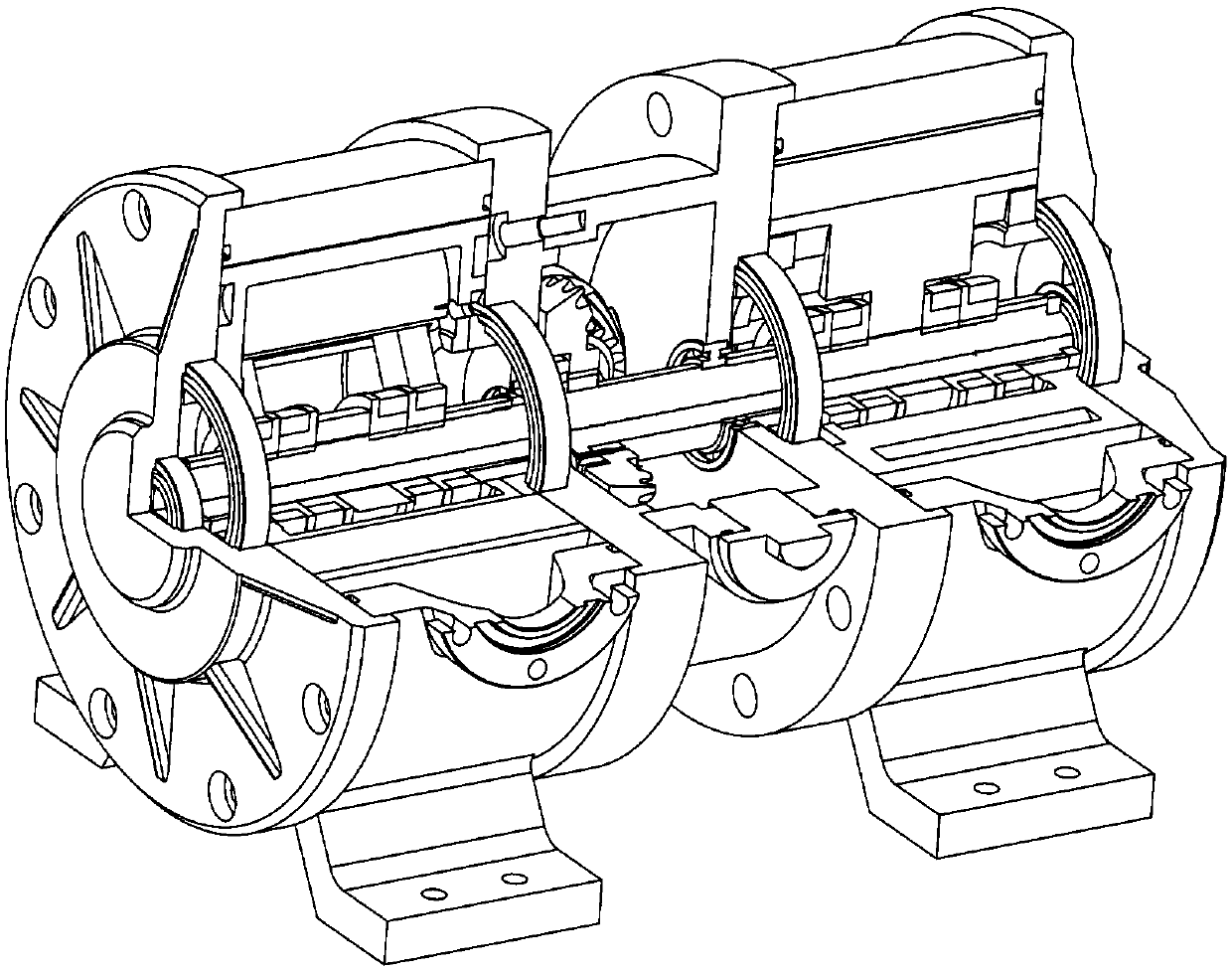

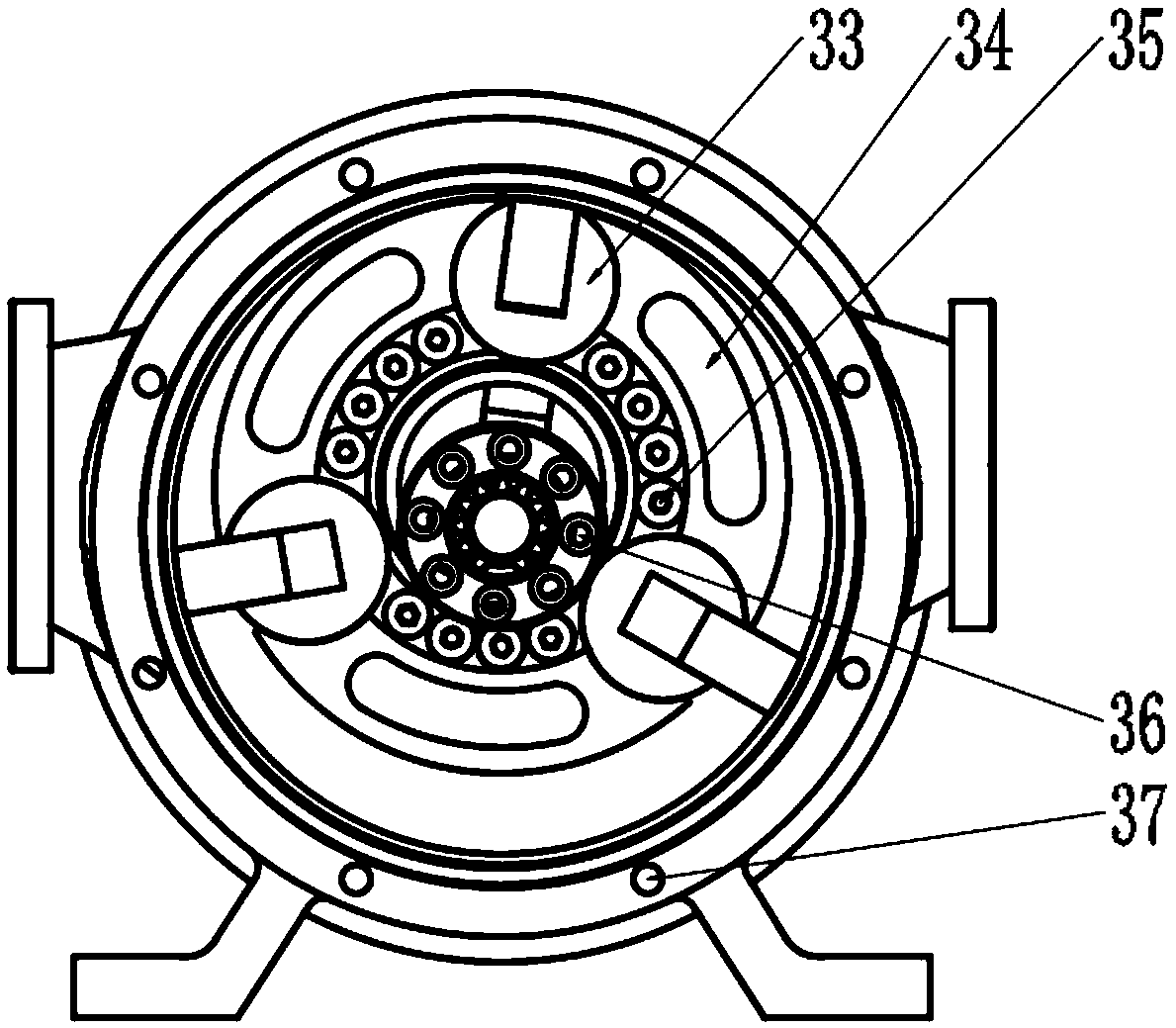

[0020] As shown in the figure, the underwater submersible propeller of the present invention includes a gear box group with power input, and a single-cylinder vane type centering rotor displacement pump for water suction and drainage, as shown in 1A, including a power input gear box and two vane-type centering rotor volumetric pumps, the power input shaft of the power input gearbox is supported on the first intermediate end cover through bearings and mechanical seals, one end of the power input shaft is connected to the power output shaft, and the other end is fixed There is a spiral bevel gear, which is matched with the spiral bevel gear on the main shaft, and the first middle end co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com