Colorless optical glass, glass prefabricated part thereof, element and instrument

A glass preform and optical glass technology, applied in optical components, optics, instruments, etc., can solve the problems of reducing costs and increasing glass production costs, and achieve the effects of easy molding, good glassness, and not easy glass bubbles

Active Publication Date: 2019-04-19

CDGM OPTICAL GLASS

View PDF17 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The object of the invention is to provide a kind of colorless optical glass, solves the problem in the prior art to overcome La 2 o 3 If the content is too high, it will affect the performance of refractive index, dispersion, crystallization upper limit temperature, etc., which needs to increase the cost of glass production; through reasonable optimization of composition and proportion, it can increase the refractive index / reduce dispersion while reducing Gd 2 o 3 and Ta 2 o 5 The amount of use, reduce costs, and ensure that the upper limit temperature of crystallization of the glass does not rise, the glass forming property is better, glass bubbles are not easy to be generated in the melting process, and good optical properties and molding properties are also guaranteed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

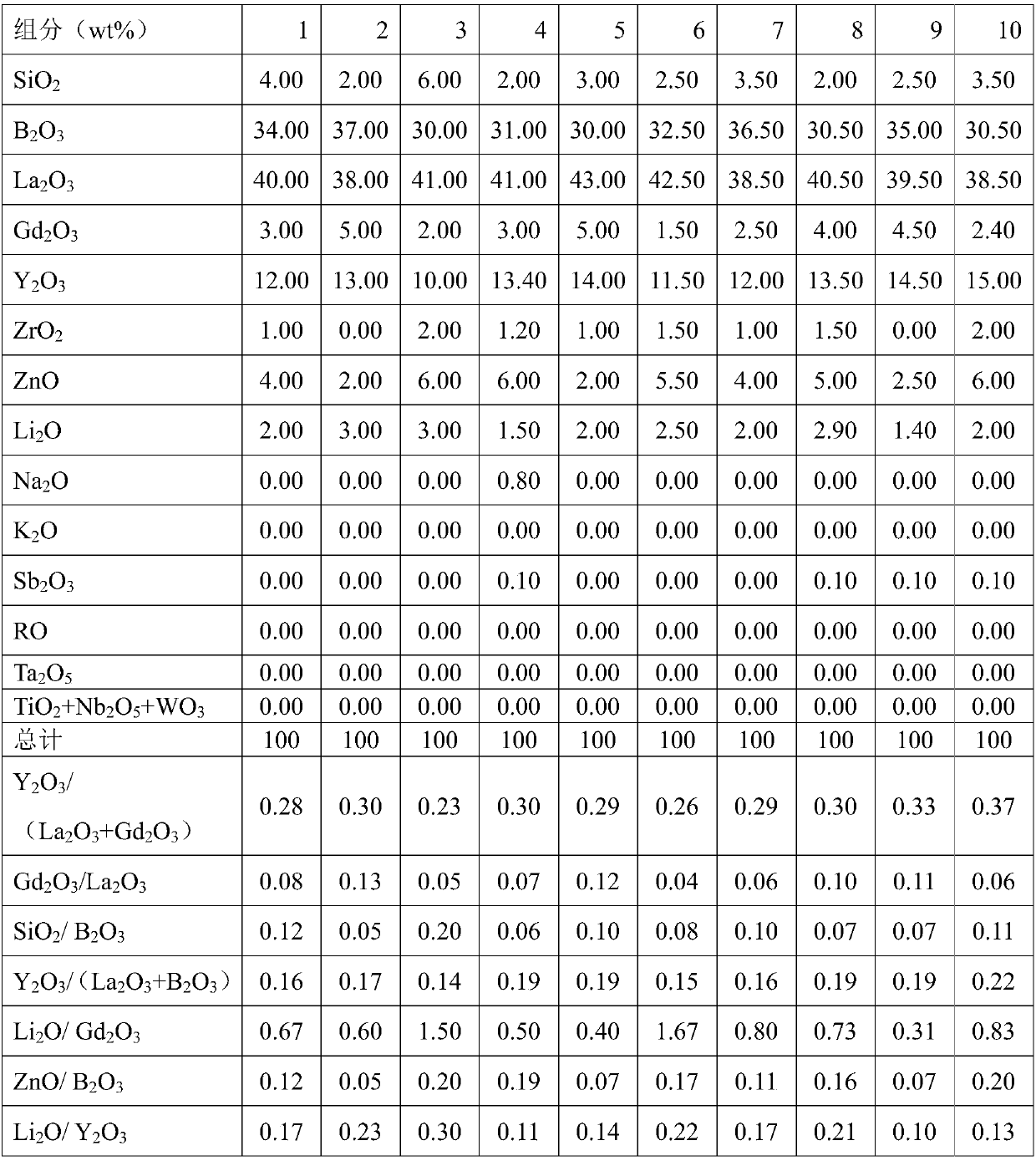

[0089] A colorless optical glass, in terms of wt%, and its specific composition and ratio are shown in Table 1-Table 4.

[0090] Table 1

[0091]

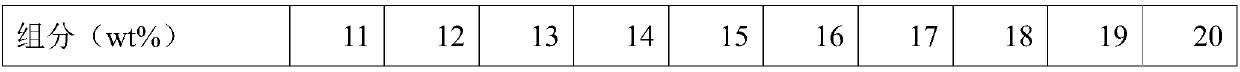

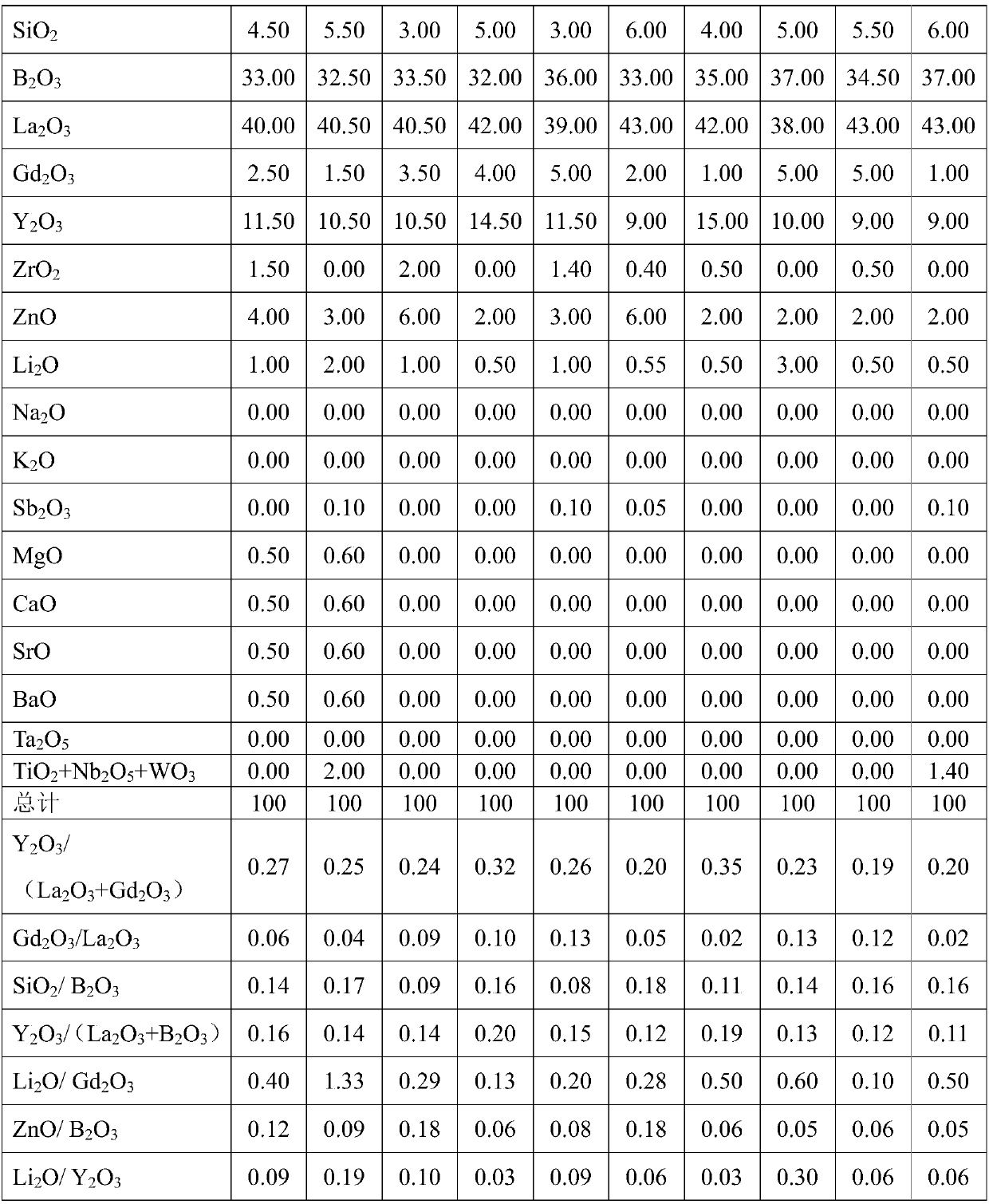

[0092] Table 2

[0093]

[0094]

[0095] table 3

[0096]

[0097]

[0098]

[0099] Table 4

[0100]

[0101]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses colorless optical glass, a glass prefabricated part thereof, an element and an instrument. The problem is solved that in the prior art, in order to overcome the influence of high La2O3 content on refractive index, chromatic dispersion, crystallization upper limit temperature and other performance, the production cost of glass needs to be increased. The glass comprises, by wt%, 25-45t% of B2O3, 30-50t% of La2O3, 0-10t% of Gd2O3 and 3-20t% of Y2O3. The specific value of Gd2O3 to La2O3 is 0.01-0.3. According to the optical glass, through reasonable optimization of composition and matching, the refractive index is increased, the chromatic dispersion is reduced, the application amount of Gd2O3 and Ta2O5 is reduced, the cost is reduced, it is effectively guaranteed that the crystallization upper limit temperature of the glass is not increased, the glass formation performance is better, glass bubbles are not easily generated in the founding process, and good optical performance and formation performance are also guaranteed.

Description

technical field [0001] The invention relates to the field of glass, in particular to a colorless optical glass and its prefabricated parts, components and instruments. Background technique [0002] Recently, there is a rapid development trend towards higher integration and function improvement in devices using optical systems, and it is increasingly desired to reduce the weight and size of optical systems. To realize this desire, optical designs using aspheric lenses made of high-performance glass are becoming mainstream. Usually, this glass is heated to a temperature acceptable for forming, and then formed by precision molding to produce an aspheric lens. In particular, although recently used large-aperture lenses are spherical lenses, these lenses are being replaced by larger-aperture aspherical lenses in order to further enhance functions. There is an increasing need for high performance glasses for the manufacture of these lenses to have high refractive index and low d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03C3/068G02B1/00

CPCC03C3/068G02B1/00

Inventor 匡波

Owner CDGM OPTICAL GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com