An anaerobic fermentation material mixing tank transmission mechanism

A transmission mechanism and material mixing technology, which is applied in the bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biomass post-processing, etc. The problem of low rigidity of the stirring device can achieve the effect of uniform force, stable transmission and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

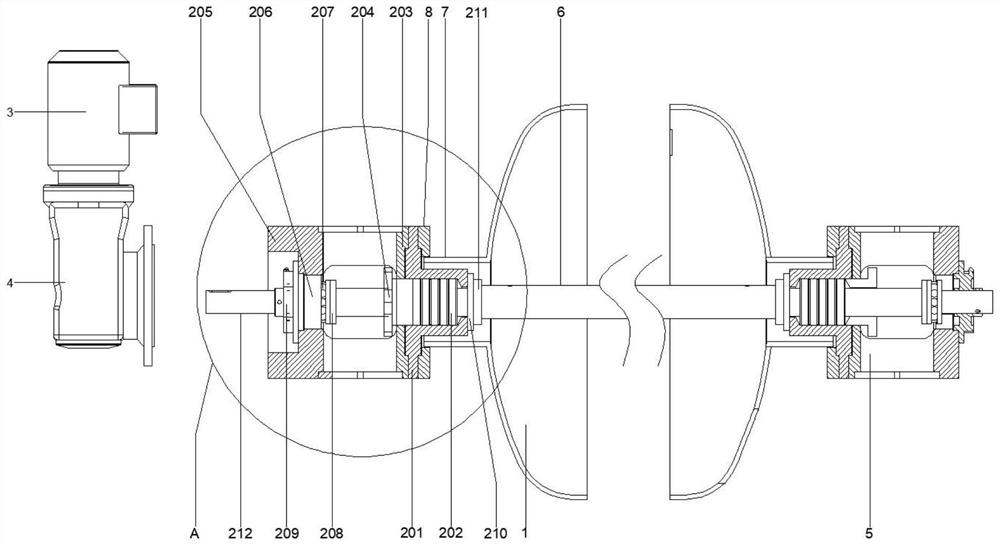

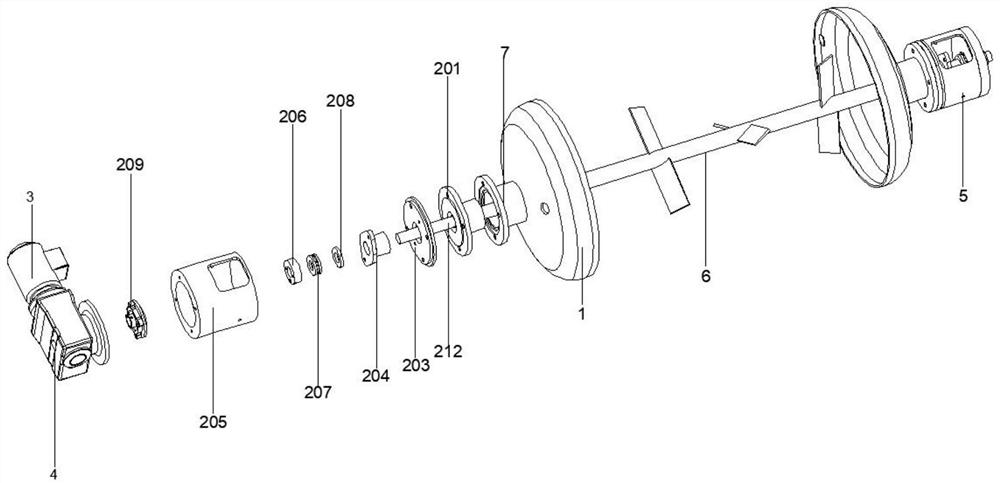

[0027] A transmission mechanism for an anaerobic fermentation material mixing tank, comprising: a tank body 1, a first transmission mechanism 2, a drive motor 3, a reducer 4, a second transmission mechanism 5, a stirring shaft 6, a connecting pipe 7, a transmission flange 8, Packing flange socket 201, graphite packing 202, packing socket flange 203, packing gland 204, packing socket 205, bearing gland 206, thrust ball bearing 207, bearing pad 208, outer spherical bearing 209, PTFE gasket 210, shaft end retaining ring 211, transmission shaft 212; the tank body 1 is a horizontal tank body; the first transmission mechanism 2 is arranged on the left side of the tank body 1, and the first transmission mechanism 2 and the tank body 1 is fixedly connected by bolts; the drive motor 3 is arranged on the left side of the first transmission mechanism 2, and the drive motor 3 and the first transmission mechanism 2 are connected through the reducer 4; the second transmission mechanism 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com