δ integration and secretion of industrial strains of Saccharomyces cerevisiae expressing cellulase and its application

A technology of cellulase and Saccharomyces cerevisiae, which is applied in the field of bioengineering, can solve the problems of low enzyme diffusion rate, achieve high-efficiency degradation, and increase the effect of ethanol yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Acquisition of host strain Kα

[0019] Sporulation culture was carried out on the highly active dry yeast of Angel Saccharomyces cerevisiae, and the haploid strain whose mating type was α was obtained by screening, and the host strain Kα was obtained by reverse selection with 5-fluoroorotic acid plate. Specific steps are as follows:

[0020] (a) Take 0.01g Angel Saccharomyces cerevisiae high active dry yeast, inoculate it in 5ml YPD liquid medium (1% yeast powder, 2% peptone, 2% glucose), and culture it at 30°C and 150rpm for 20h.

[0021] (b) Use an inoculation needle to dip a part of the bacterial liquid and streak the YPD solid medium (1% yeast powder, 2% peptone, 2% glucose, 1.8% agar powder) plate, cultivate at 30°C until the colony is 2-3mm, pick a single The colonies were inoculated into 3 mL of YPD liquid medium and cultured at 30°C and 150 rpm for 20 h, then 50 μl of bacterial liquid was inoculated into 3 mL of YPD liquid medium and cultured at 30°C and 150 rp...

Embodiment 2

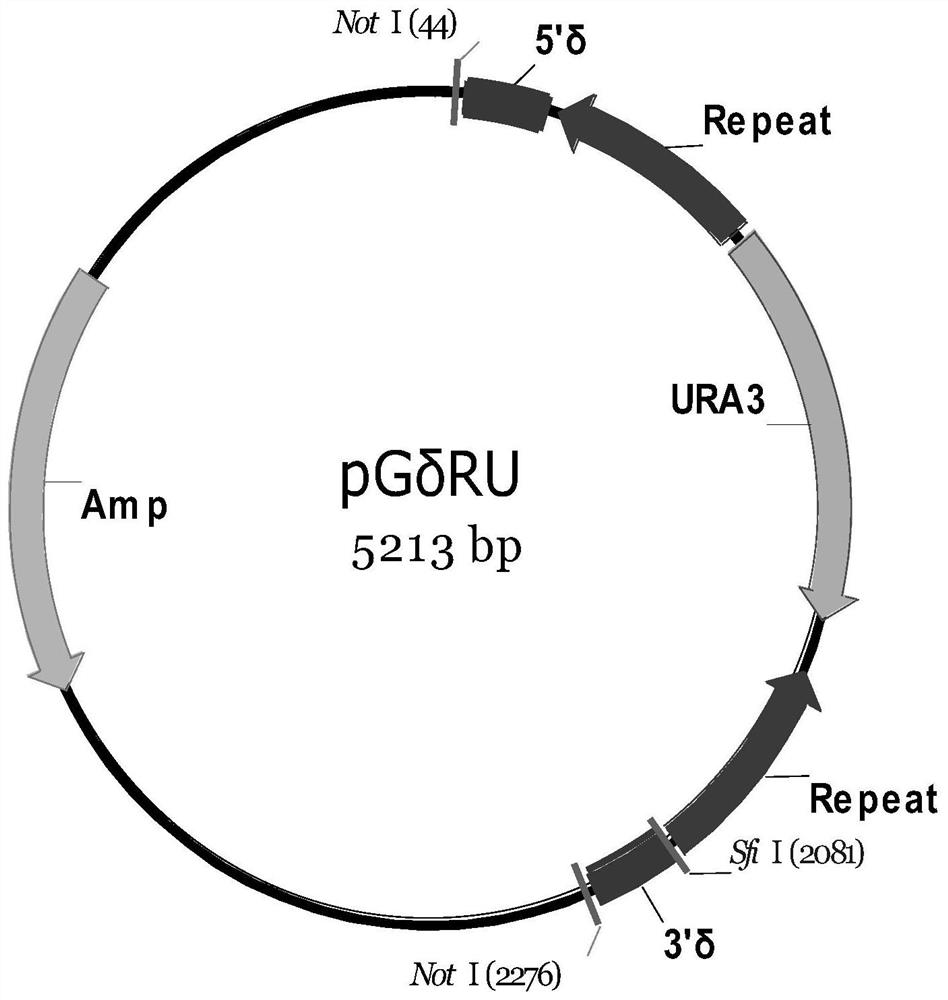

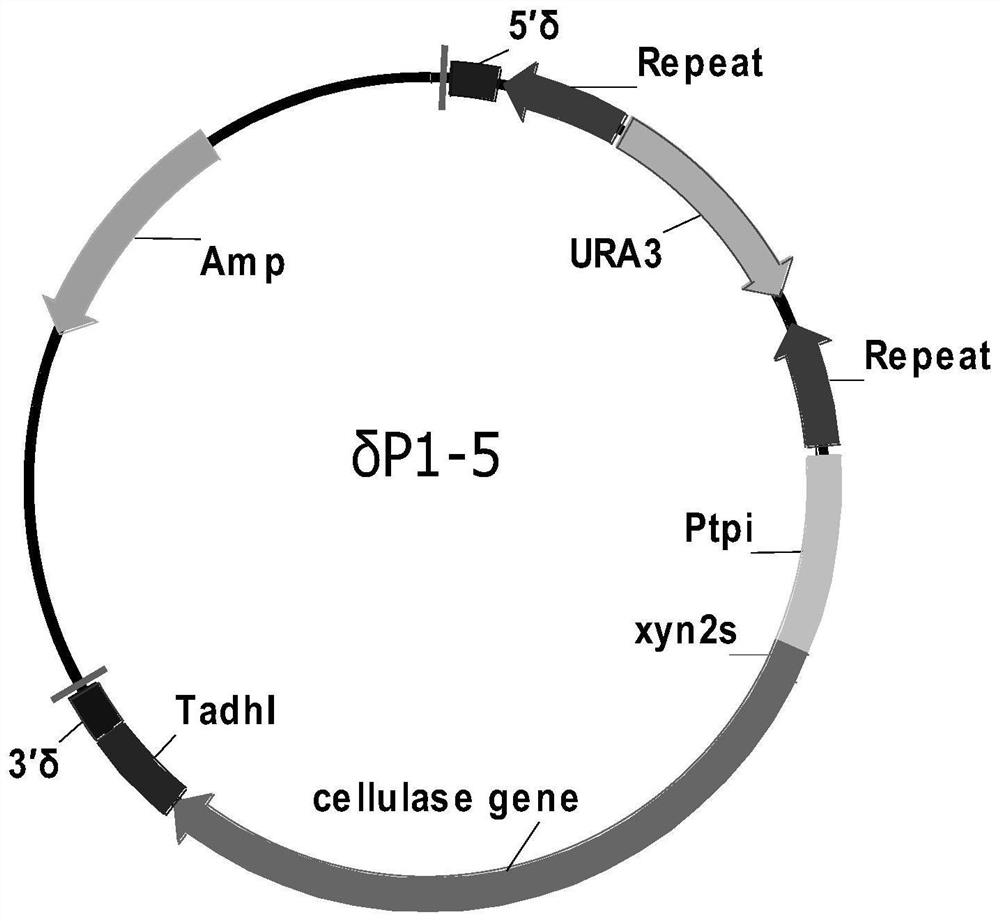

[0035] Construction of Cellulase Gene Expression Cassette δ Integration Plasmid

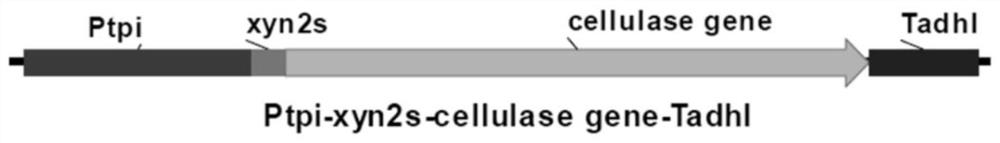

[0036] The schematic diagram of the cellulase gene expression cassette is shown in figure 1 , wherein Ptpi is (Saccharomyces cerevisiae triose phosphate isomerase promoter) promoter, xyn2s (Trichoderma reesei xylanase secreted peptide) is secreted peptide, cellulase gene is cellulase gene exon sequence, Tadh I (Saccharomyces cerevisiae alcohol dehydrogenase terminator) is the terminator. The cellulase genes include cbh1, cbh2, egl2 derived from Trichoderma reesei and bgl1, cbh1 derived from Aspergillus aculeatus.

[0037] The construction of the above five cellulase gene expression cassettes can be found in our work (Hong Jiefang. Construction of Saccharomyces cerevisiae engineering strains expressing cellulase and their research on the production of alcohol by fermentation of lignocellulose. 2014 Tianjin University doctoral dissertation; Zhang Weina. Expression Construction of Saccharomyces ce...

Embodiment 3

[0051] Yeast Transformation and Screening

[0052] After the plasmid δP1 was digested with NotI and the nucleic acid was purified, the host strain Kα was transformed by the lithium acetate method, and the transformants were screened on the basic medium plate with default uracil, and then reverse-selected on the 5-fluoroorotic acid plate to obtain URA3 The labeled transformant Kαδ1 was screened.

[0053] After the plasmid δP2 was digested with NotI and the nucleic acid was purified, the host strain Kαδ1 was transformed by the lithium acetate method, and the transformants were screened on the basic medium plate with default uracil, and then reverse-selected on the 5-fluoroorotic acid plate to obtain URA3 The labeled transformant Kαδ2 was screened.

[0054] After the plasmid IP3 was digested with NotI and the nucleic acid was purified, the host strain Kαδ2 was transformed by the lithium acetate method, the transformants were screened on the basic medium plate with default uracil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com