Abrasion-resistant anti-pill blended yarn and preparation method thereof

A blended yarn and anti-pilling technology, which is applied in the direction of yarn, textiles, papermaking, fiber treatment, etc., can solve the problems of poor wear resistance of blended yarns, and achieve the effect of not easy to pill and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

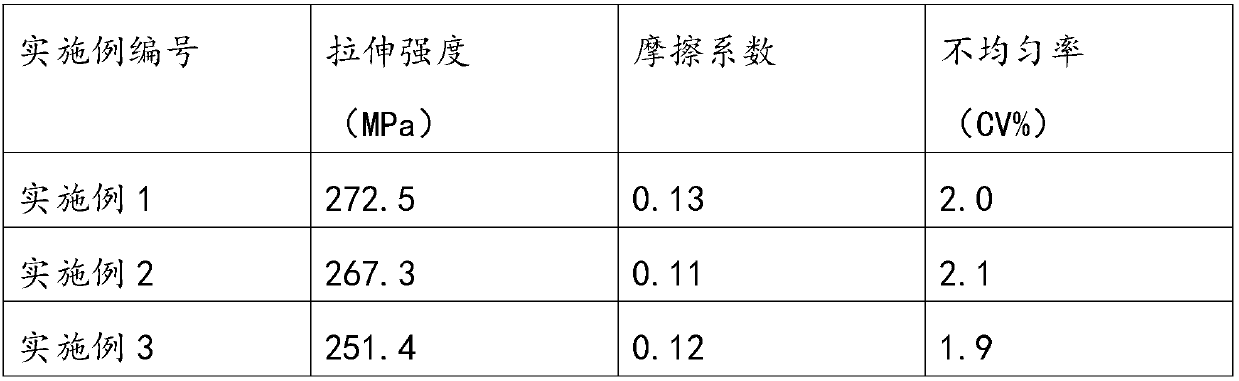

Examples

preparation example Construction

[0024] The present invention also provides a preparation method for the above-mentioned wear-resistant and anti-pilling blended yarn, comprising the following steps:

[0025] S1. In parts by weight, each raw material is weighed and the cotton fiber is pretreated;

[0026] S2. Dividing the pretreated cotton fibers into a first portion of cotton fibers and a second portion of cotton fibers, the mass ratio of the first portion of cotton fibers to the second portion of cotton fibers being 0.83 to 1.2:1;

[0027] S3. Mix the first cotton fiber and polyacrylonitrile fiber of the pretreatment and make the first cotton roll, and the second cotton fiber, cupro ammonia fiber, flax fiber and ultra-high molecular weight polyethylene fiber of the pretreatment blend and form a second lap;

[0028] S4. making the first lap and the second lap into a first sliver and a second sliver, respectively;

[0029] S5. The first raw sliver and the second raw sliver are processed into a mature sliver ...

Embodiment 1

[0038] Prepare wear-resistant and anti-pilling blended yarn, the preparation method is as follows:

[0039] (1) Weigh 60 parts of cotton fiber (including 30 parts of long-staple cotton and 30 parts of fine-staple cotton), 25 parts of polyacrylonitrile fiber, 15 parts of cupro ammonia fiber, 7 parts of flax fiber and 2 parts of ultra-high molecular weight polyethylene fiber ;

[0040] (2) After mixing the long-staple cotton and fine-staple cotton evenly, place them in a 7% aqueous urea solution, soak for 1 to 1.5 hours, and atomize and spray 4.8 parts by weight of modified nano-SiO 2 Powder, stand for 10-12 hours;

[0041] (3) The pretreated cotton fiber is divided into 30 parts of the first part of cotton fiber and 30 parts of the second part of cotton fiber according to parts by weight, and the first part of cotton fiber and polyacrylonitrile fiber are mixed and cleaned through the first The first cotton roll is produced in the process, the beater speed is controlled at 580...

Embodiment 2

[0045] Prepare wear-resistant and anti-pilling blended yarn, the preparation method is as follows:

[0046] (1) Weigh 70 parts of cotton fiber (including 46 parts of long-staple cotton and 24 parts of fine-staple cotton), 18 parts of polyacrylonitrile fiber, 10 parts of cupro ammonia fiber, 10 parts of flax fiber and 1 part of ultra-high molecular weight polyethylene fiber ;

[0047] (2) After mixing the long-staple cotton and fine-staple cotton evenly, place them in a 7% aqueous urea solution, soak for 1 to 1.5 hours, and atomize and spray 10.5 parts by weight of modified nano-SiO 2 Powder, stand for 10-12 hours;

[0048] (3) The pretreated cotton fiber is divided into 38 parts of the first part of cotton fiber and 32 parts of the second part of cotton fiber according to parts by weight, and the first part of cotton fiber and polyacrylonitrile fiber are mixed and cleaned through the first The first cotton roll is produced in the process, the beater speed is controlled at 600r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com