Super-tough concrete bridge shock-proof system

A concrete and bridge technology, applied in the field of bridge shock absorption, can solve problems affecting bridge safety, large lateral slippage of pouring caps, disconnection of bridge piers and bridge decks, etc., to improve absorption capacity, reduce impact, and increase anti-shock Shocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

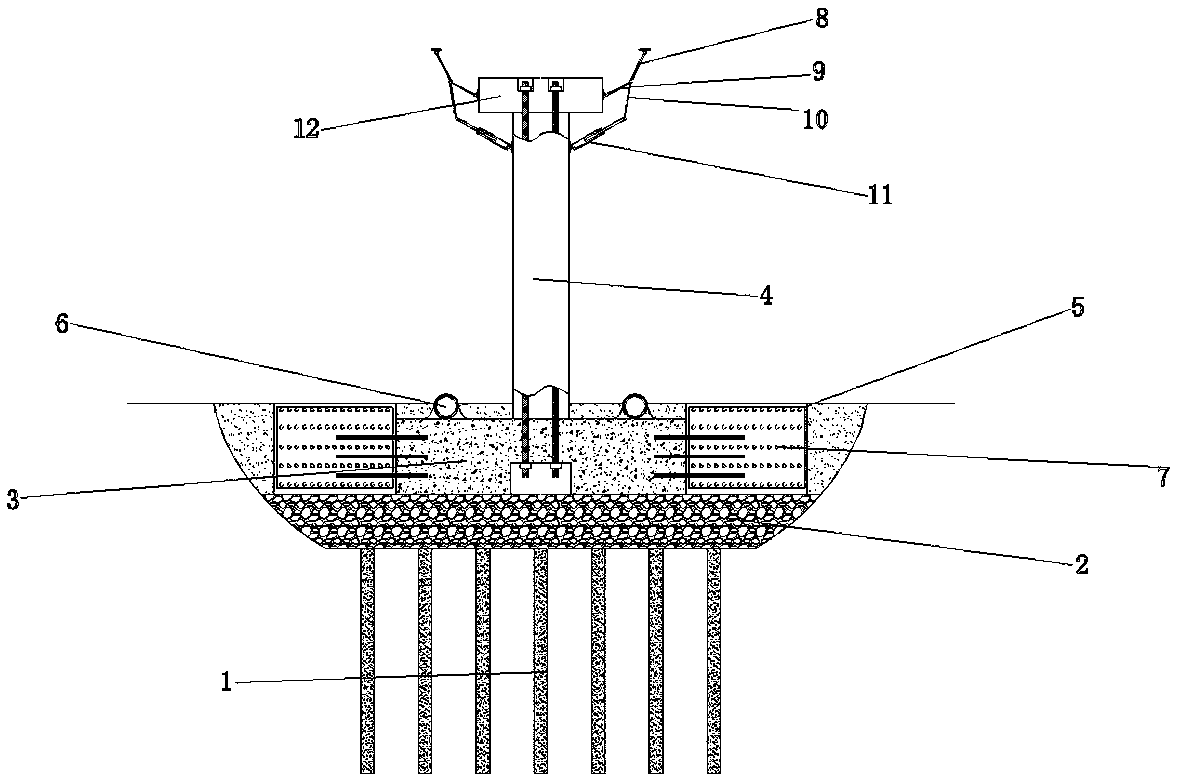

[0014] Such as figure 1 As shown, a shock-absorbing system for a super-tough concrete bridge includes a pile group 1 arranged on the foundation soil layer, a gravel layer 2 is covered above the pile group 1, a pouring cap 3 is placed above the gravel layer 2, and a pouring cap 3 is placed above The pier 4 is connected, and the top of the pier 4 is provided with a cover beam 12; the pouring cap 3 is equipped with a wave power generation device 6, and the wave power generation device 6 includes a body with an inner cavity and piezoelectric crystals installed at both ends of the body. There are steel balls that can roll freely in the body, and there is a sulfur concrete box 5 around the pouring cap 3, and sulfur concrete is poured in the sulfur concrete box 5, and a heating wire is embedded in the sulfur concrete, and the heating wire is connected to the wave power generation device 6. connection; when earthquake fluctuations occur, the steel ball in the wave power generation dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com