Axial flow pump

An axial-flow pump and bearing technology, applied in the field of axial-flow pumps, can solve the problems of large volume, low lift, and limited application range of axial-flow pumps, and achieve the effects of simple operation, low price, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

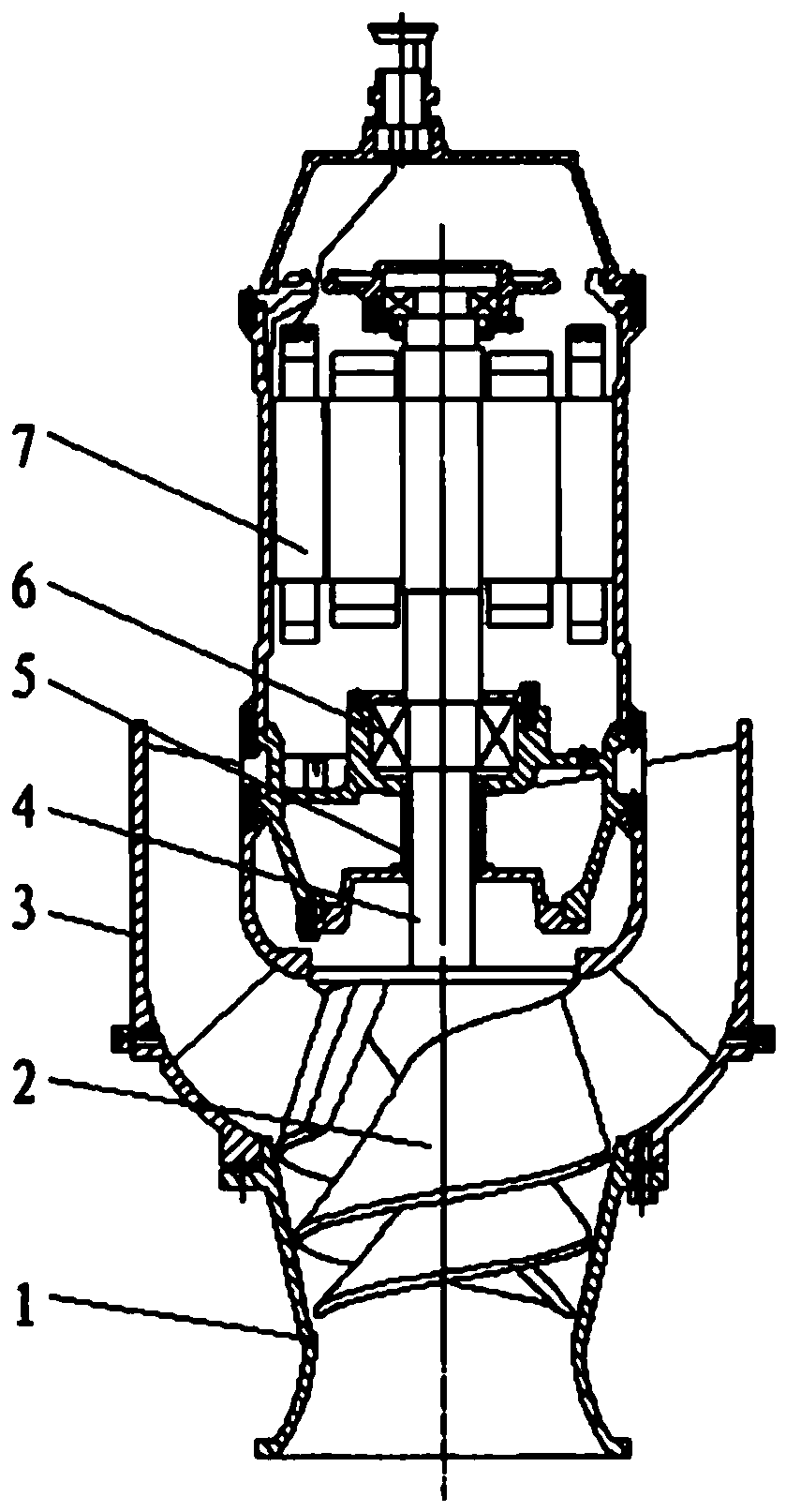

[0017] exist figure 1 Among them, the axial flow pump is composed of a shell part and a pump body part, and is mainly composed of a submersible motor, a bearing, a shaft, a guide vane, a shaft and an impeller; the pump body part of the axial flow pump is composed of a bearing, a motor, a guide vane , an impeller and a shaft; the blade tip clearance size of the blade is 20-30% smaller than the conventional size; the impeller is fixed on the rotating shaft, and the impeller is located below the inner cylinder of the guide vane; the lower end of the housing The shape of the bell mouth; the blades stand on the surface of the wheel center cone with a certain inclination angle and spacing, and its structural shape is similar to a helical propeller with a small end radius and a large root radius, and the outlet part is axial flow.

[0018] The working mode of the axial flow pump is as follows: the blades of the helical impeller stand on the surface of the center cone with a certain i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com