Method for monitoring deformation of pipe concrete filled in steel pipe arch of super-large bridge

A technology of deformation monitoring and steel pipe arching, which is applied to measuring devices, instruments, and optical devices, etc., can solve the problems of denaturation damage, sensor lead corrosion, manual monitoring, etc., and achieve stable properties and long-term stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0204] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

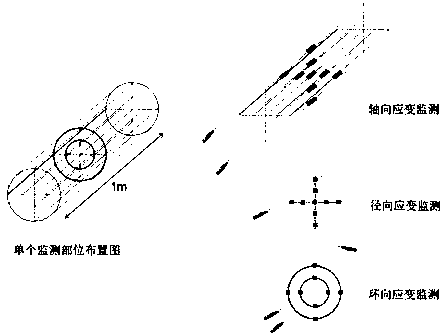

[0205] Example. A method for monitoring the deformation of concrete in the tube poured into the steel tube arch of a super-large bridge, such as Figure 1 to Figure 8 As shown, by using fiber Bragg grating technology to detect the drift of the central wavelength of reflected light, the strain of the concrete structure poured into the steel pipe arch of the super-large bridge is monitored.

[0206] The method is to use the optical fiber Bragg grating technology to measure the variable of the wavelength value of the optical fiber, calculate the strain, stress and axial force according to the variable of the optical fiber wavelength value, and monitor the strain of the concrete structure poured into the steel pipe arch of the super-large bridge.

[0207] The strain is calculated using the formula: Calculation, where λ z0 , lam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com