Drawing platform and cleaning detection method using same

A detection method and technology to be detected, applied in the field of cleaning detection and extraction table, can solve the problems of scrapped containers, inability to take out cleaning liquid and other foreign objects such as dust and impurities, and achieve the effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

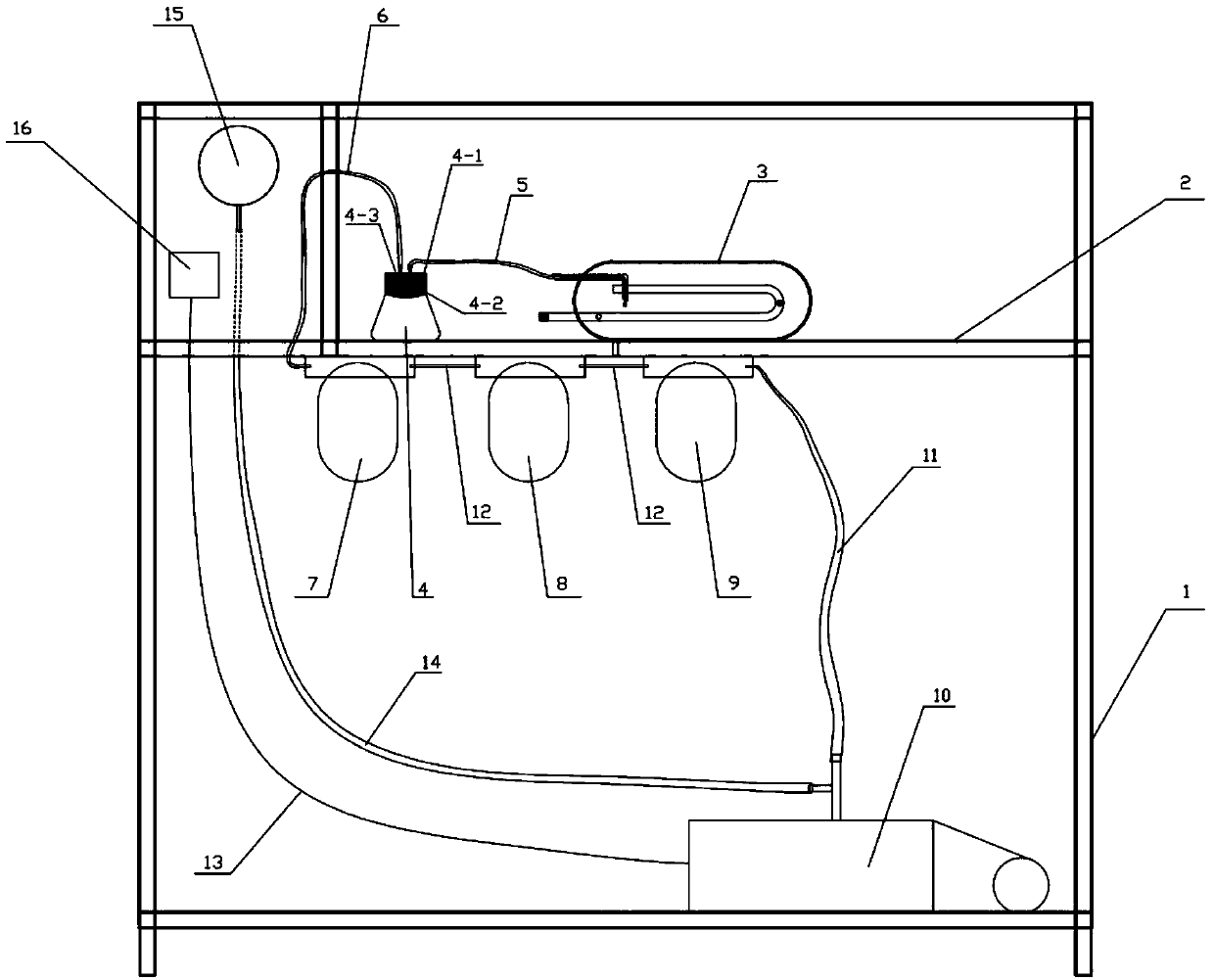

[0031] Embodiment 1, as figure 1 As shown, a drawer includes a cabinet 1, a pressure gauge 15 and a power switch 16 are provided on one side of the cabinet 1, an operation console 2 is arranged inside the cabinet 1, and a cone is arranged on the top surface of the console 2. Shaped bottle 4 and detected object 3, the top of the Erlenmeyer bottle 4 is provided with a rubber stopper 4-1, and the rubber stopper 4-1 is provided with a liquid inlet pipe 4-2 and a liquid outlet pipe 4-3. The liquid pipe 4-2 is connected to one end of the liquid inlet hose 5, the liquid outlet pipe 4-3 is connected to one end of the liquid outlet hose 6, and the other end of the liquid inlet hose 5 is connected to the detected object 3; The rubber hose 12 is connected in series with a water-splitting air filter I 7, a water-separating air filter II 8, and a water-separating air filter III 9. The inflator III 9 is connected to the vacuum pump 10 through the rubber pipe I11 , the vacuum pump 10 is con...

Embodiment 2

[0032] Embodiment 2, as figure 1 As shown, a method for cleaning and detecting an extraction table includes the following steps:

[0033] ①. Put the cleaning liquid container into the drying oven and heat it up to 100 degrees to dry for 30 minutes, then take it out and let it cool down to room temperature for later use;

[0034] ②. Take a piece of medium-speed qualitative filter paper and weigh it and record it. Fold the filter paper into a cone shape and put it in a 100-degree drying oven to dry for 30 minutes. Take it out and store it in an airtight container for later use;

[0035] ③. Select the detected object 3 at the production site and make a serial number identification;

[0036] ④. Pour the cleaning solution into the container containing the cleaning solution in step ①, weigh and record, the object to be tested: cleaning solution = 1 liter: 100 ml metered addition;

[0037] ⑤. Pour the cleaning solution in step ④ into the detected object 3 in step ③;

[0038] ⑥. St...

Embodiment 3

[0049] Embodiment 3, on the basis of embodiment 2, described cleaning solution is denatured alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com