Method for detecting overall quality of air hole and shrinkage cavity flaw of aluminum alloy die pressed casting

A quality inspection and die-casting technology, which is applied in the field of aluminum alloy die-casting, can solve problems such as inaccurate detection methods, high skill requirements for operators, and radiation pollution in the environment, and achieve the effect of convenient detection process and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

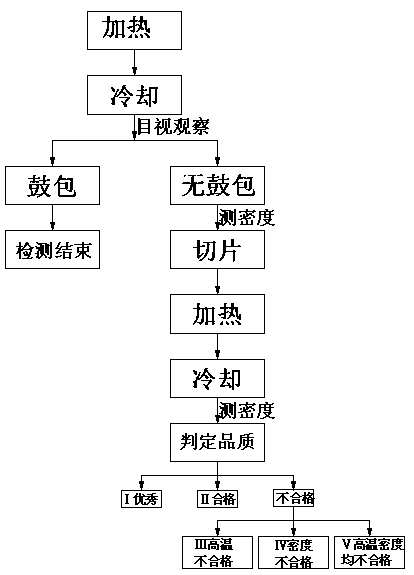

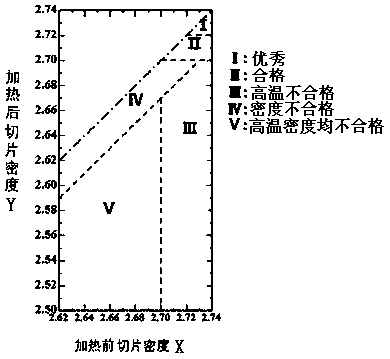

[0014] The flow chart of a specific embodiment of the overall quality detection method of air holes and shrinkage defects of aluminum alloy die castings according to the present invention is as follows figure 1 As shown, the detection method of the present embodiment comprises the following steps:

[0015] (1) Heat the aluminum alloy die casting to be tested to 480~550°C, keep it warm for 1~2 hours, and then cool the heated aluminum alloy die casting to room temperature naturally;

[0016] (2) Observe the bulge on the surface of the aluminum alloy die-casting after natural cooling. If a bulge is observed, it is determined that the aluminum alloy die-casting has air hole defects, and the inspection is over; if no bulge is observed, the aluminum alloy die-casting is inspected. The next step is shrinkage cavity detection;

[0017] (3) Slice th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com