Polishing and drying method for pumpkin seeds

A drying method and technology of pumpkin seeds, which are applied in the fields of food drying, seeds preservation by drying, food science, etc., can solve problems such as harmful health, affecting the shelf life, and failure, and achieve extended shelf life, extended shelf life, and even taste distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The present embodiment provides a kind of fried pumpkin seeds peeled, and the specific processing process is as follows:

[0029] (1) Material selection, using specific gravity machines, color sorters, etc. to remove various impurities and heterogeneous seeds, and select plump pumpkin seeds that meet the requirements;

[0030] (2) Prepare soup liquid A, mix Luo Han Guo, yam, Poria cocos, Gorgon fruit, mint, ginseng and water in a mass ratio of 10:10:10:4; 4:0.025:1500, heat to boiling, and then Boil under high pressure for 1.5 hours to release the functional substances and characteristic aromas of Chinese herbal medicines, control the boiling temperature to 80°C-90°C, and filter to obtain soup liquid A;

[0031] (3) Prepare soup stock liquid B, mix table salt, white sugar, brown sugar, brown sugar syrup, and soup stock liquid A in a mass ratio of 200:100:100:50:1500, and cook for 30 minutes to obtain stock liquid B, where the brown sugar and brown sugar syrup help to e...

Embodiment 2

[0036] A method for polishing and drying pumpkin seeds, comprising the following steps:

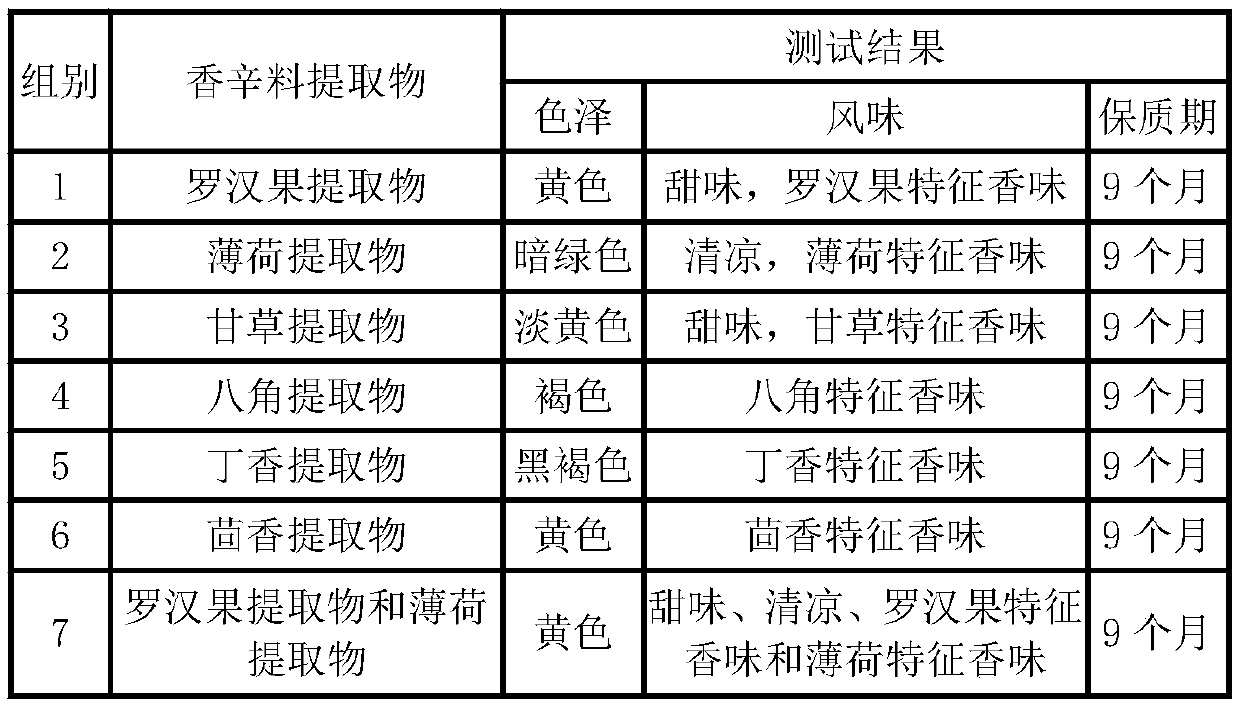

[0037] (1) Preparation of polishing liquid: water and spice extracts were mixed in a mass ratio of 10:1 to prepare a polishing liquid. The spice extract can be obtained by pressing the spices to extract the juice; or the spices and water are boiled to a slight boil for 2-3 hours under normal pressure, and then filtered and cooled.

[0038] (2) Polishing treatment: first add the semi-finished pumpkin seeds fried and peeled in Example 1 to the polishing pot, heat it to 70°C-80°C while turning over, and then spray the polishing solution into the polishing pot through the nozzle to mix with the pumpkin seeds. This way can fully mix the polishing liquid and melon seeds evenly in a short time, so that the taste of the melon seeds is more evenly distributed; the amount of polishing liquid added is 5% of the weight of pumpkin seeds, and the temperature range is 70°C-90°C, and maintain In this te...

Embodiment 3

[0044] A method for polishing and drying pumpkin seeds, comprising the following steps:

[0045] (1) Preparation of polishing liquid: mix Luo Han Guo extract and peppermint extract at a ratio of 1:1, and then mix with water at a mass ratio of 70:1 to prepare a polishing liquid.

[0046] (2) Polishing treatment: first add the semi-finished pumpkin seeds fried and peeled in Example 1 to the polishing pot, heat to 80°C-90°C while turning over, then spray the polishing solution into the polishing pot through the nozzle and mix with the pumpkin seeds. The amount of polishing liquid added is 10% of the weight of the pumpkin seeds, so that the polishing liquid is evenly distributed on the surface of the melon seeds, and the temperature is raised to 90°C-110°C, and the turning polishing process is carried out at this temperature. The turning polishing time is 20min, and the melon seeds After the surface is bright, it is taken out of the pan, cooled to room temperature and packaged to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com