Cutting tool for small hollow pipe with band sawing machine and using method thereof

A technology of band sawing machine and hollow tube, which is applied in the direction of sawing machine, metal sawing equipment, manufacturing tools, etc. It can solve the problems of easy injury to cutting personnel, falling on other objects, and no fixing device, etc., and achieves simple structure, The effect of small applied force and easy processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

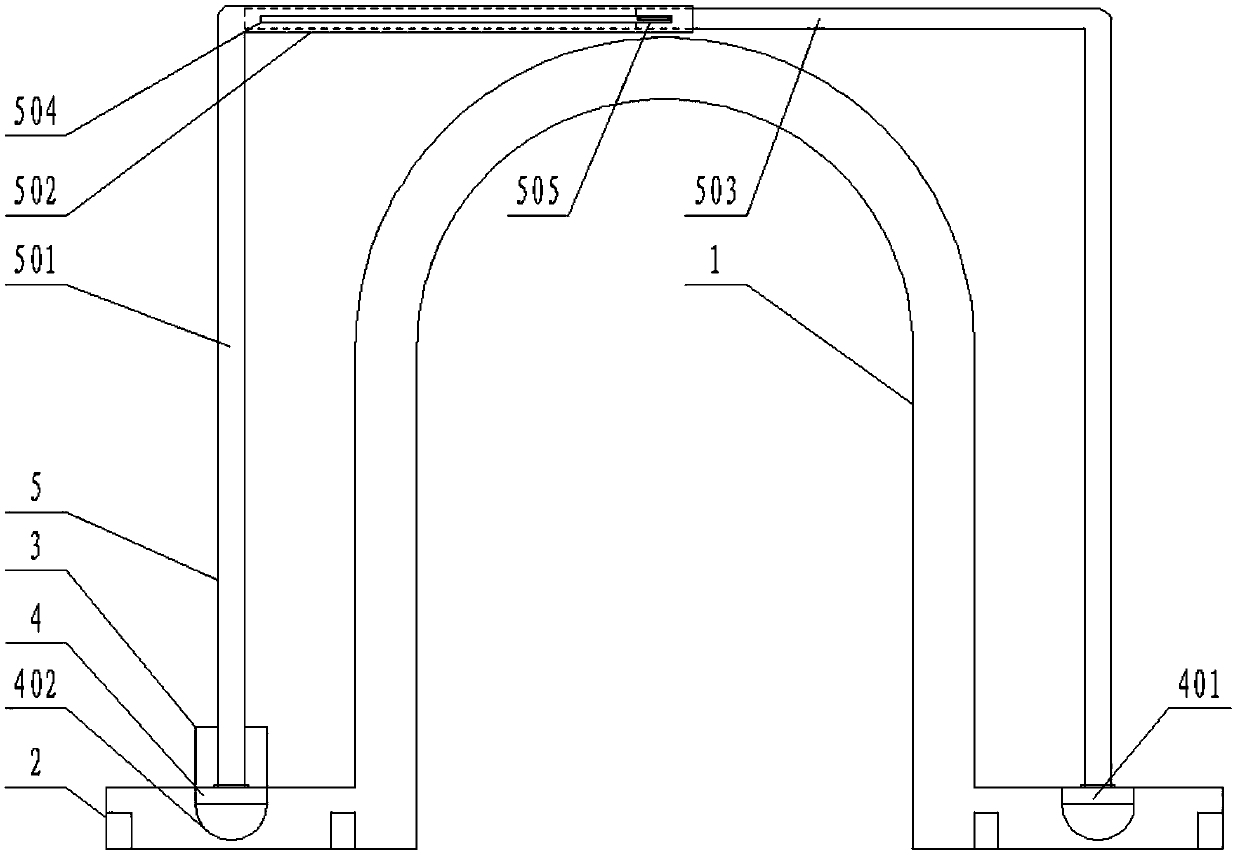

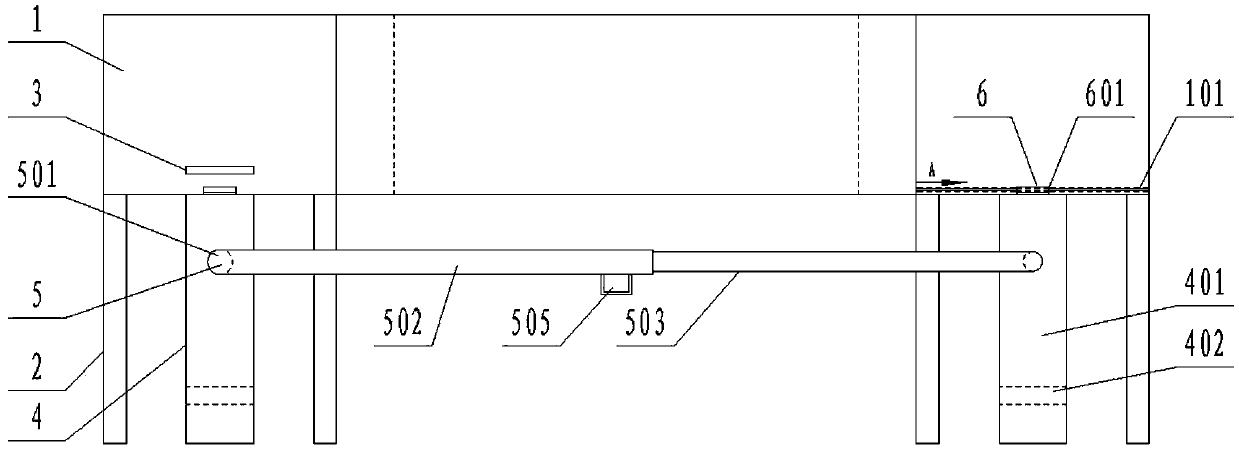

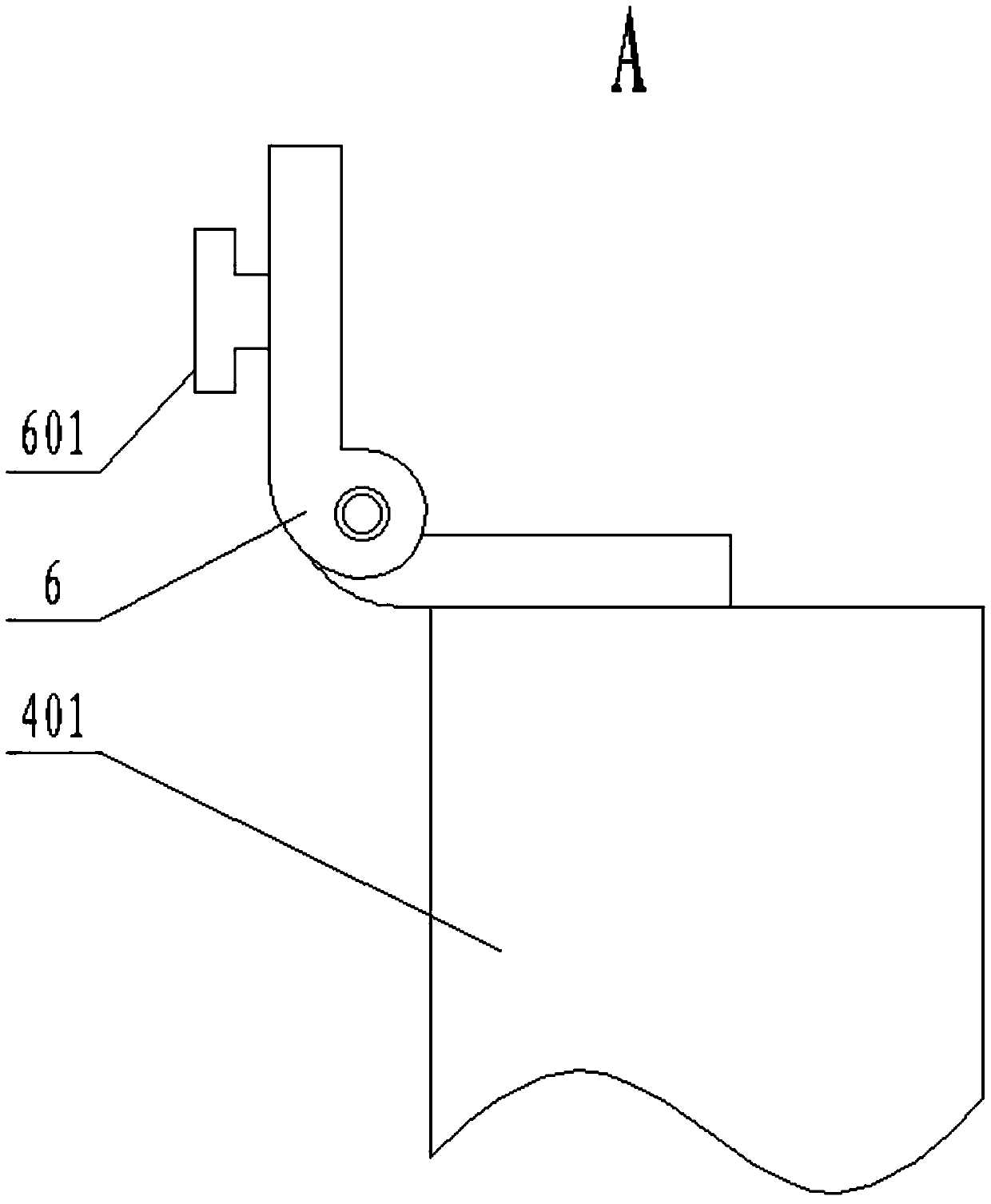

[0024] as attached figure 1 to attach image 3 Shown: a hollow pipe cutting tool for a small band sawing machine, including a frame 1, a T-shaped slot 101, a claw 2, a rotation limiting baffle 3, a left pressing plate 4, a right pressing plate 401, a limiting plate 402, and a connection Rod 5, vertical tube 501, first horizontal tube 502, second horizontal tube 503, opening groove 504, handle 505, right hinge 6 and slider 601; the frame 1 is an inverted U-shaped structure, and the left and right ends are Flat plate structure; the claw 2 is a rectangular bar structure, with four places in total, welded on the front side of the frame 1, two places on the left and right; the left pressing plate 4 is a rectangular plate structure, connected to the left end of the frame 1 in parallel through a hinge on the front side of the plate; the limiting plate 402 is a semicircular plate structure, there are two places, welded on the lower side of the left pressing plate 4 and the right pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com