A kind of reusable gift packaging composite plastic film and preparation method

A composite plastic and gift technology, applied in the field of plastic packaging film, can solve the problems of resource waste, environmental impact, etc., and achieve the effects of eliminating wrinkles, improving crystallinity, and increasing elastic recovery force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

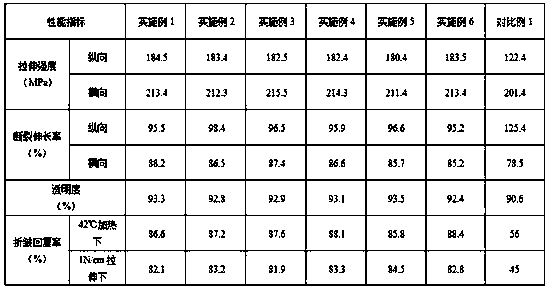

Examples

Embodiment 1

[0030] (1) Add polytrimethylene terephthalate pellets, light stabilizers, antioxidants, and nucleating agents into a high-speed mixer, heat and mix evenly, and cool naturally after discharging to obtain Mixture 1; Mixture 1 Among them, 97.5 parts by weight of polytrimethylene terephthalate pellets, 1.4 parts by weight of light stabilizer, 0.7 parts by weight of antioxidant, and 0.4 parts by weight of nucleating agent; the heating temperature of high-speed mixing is 170 ° C, and the speed is 130 r / min , the time is 16min;

[0031] (2) Add polypropylene granules, transparent talc powder, light stabilizer, antioxidant, and coupling agent into a high-speed mixer, heat and mix evenly, and cool naturally after discharging to obtain Mixture 2; , 83.5 parts by weight of polypropylene pellets, 13 parts by weight of transparent talcum powder, 0.4 parts by weight of light stabilizer, 0.1 parts by weight of antioxidant, 1 to 2 parts by weight of coupling agent; the heating temperature of ...

Embodiment 2

[0037] (1) Add polytrimethylene terephthalate pellets, light stabilizers, antioxidants, and nucleating agents into a high-speed mixer, heat and mix evenly, and cool naturally after discharging to obtain Mixture 1; Mixture 1 Among them, 97.8 parts by weight of polypropylene terephthalate pellets, 1.3 parts by weight of light stabilizer, 0.6 parts by weight of antioxidant, and 0.3 parts by weight of nucleating agent; the heating temperature of high-speed mixing is 165 ° C, and the speed is 125 r / min , the time is 18min;

[0038] (2) Add polypropylene granules, transparent talc powder, light stabilizer, antioxidant, and coupling agent into a high-speed mixer, heat and mix evenly, and cool naturally after discharging to obtain Mixture 2; , 85.1 parts by weight of polypropylene pellets, 13 parts by weight of transparent talcum powder, 0.4 parts by weight of light stabilizer, 0.1 parts by weight of antioxidant, and 1.4 parts by weight of coupling agent; the heating temperature of hi...

Embodiment 3

[0044] (1) Add polytrimethylene terephthalate pellets, light stabilizers, antioxidants, and nucleating agents into a high-speed mixer, heat and mix evenly, and cool naturally after discharging to obtain Mixture 1; Mixture 1 Among them, 97 parts by weight of polytrimethylene terephthalate pellets, 1.7 parts by weight of light stabilizer, 0.8 parts by weight of antioxidant, and 0.5 parts by weight of nucleating agent; , the time is 13min;

[0045] (2) Add polypropylene granules, transparent talc powder, light stabilizer, antioxidant, and coupling agent into a high-speed mixer, heat and mix evenly, and cool naturally after discharging to obtain Mixture 2; , 83.8 parts by weight of polypropylene pellets, 14 parts by weight of transparent talcum powder, 0.4 parts by weight of light stabilizer, 0.2 parts by weight of antioxidant, and 1.6 parts by weight of coupling agent; min, the time is 35min;

[0046] (3) Add polypropylene terephthalate pellets, antistatic agent, antibacterial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com