Water-oil separation container for swill

A water-oil separation and container technology, which is applied in liquid separation, separation methods, liquid separation auxiliary equipment, etc., can solve the problems of large water content in stagnant water, lack of stagnant oil treatment equipment, and high transportation costs, and achieve the effect of rapid water-oil separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

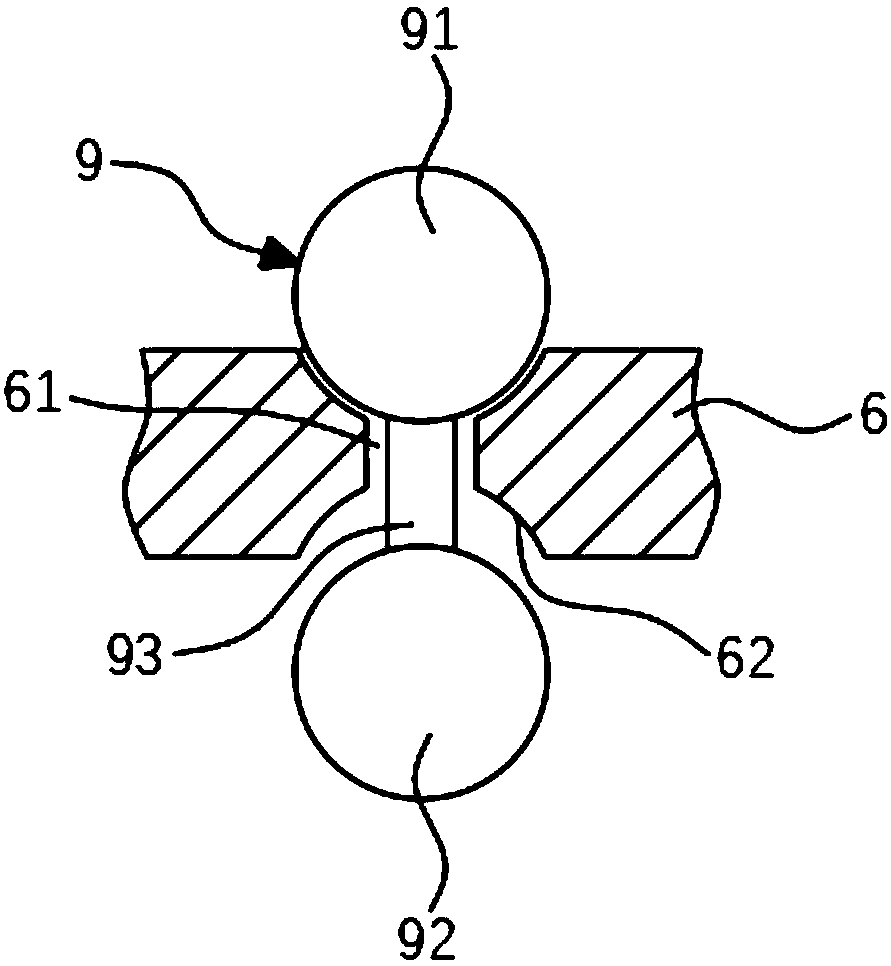

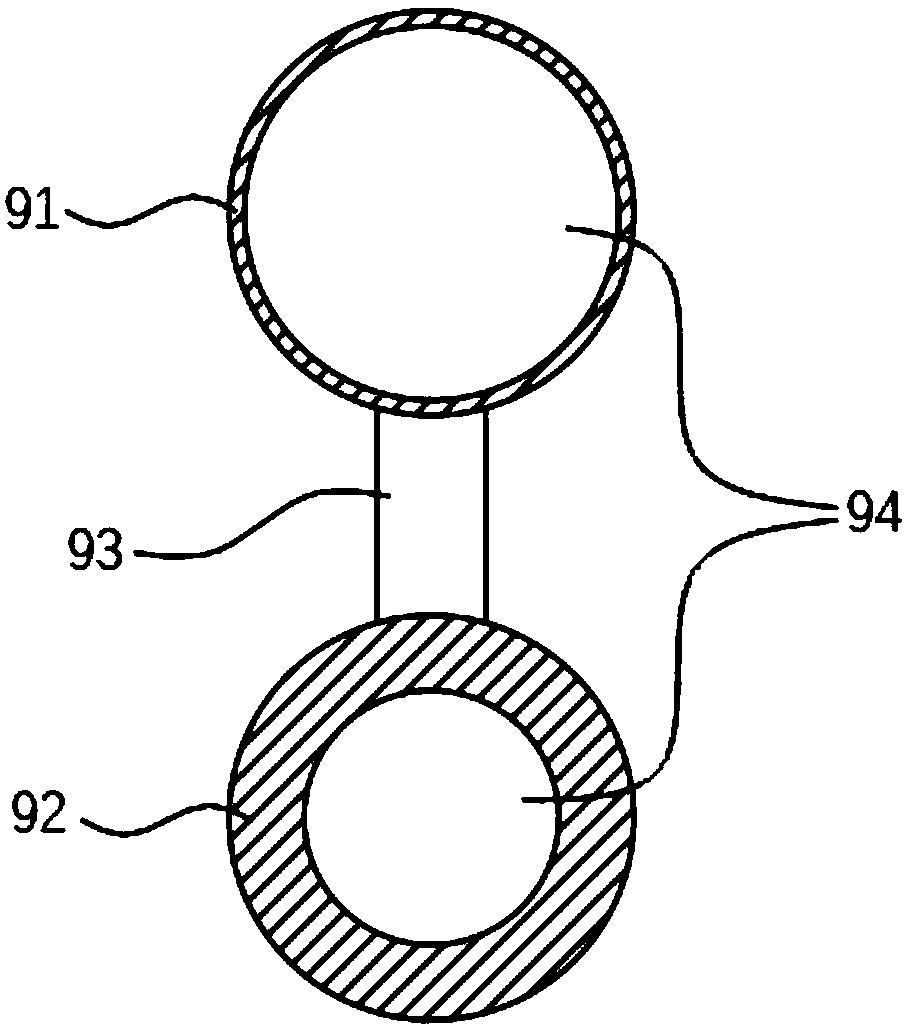

[0030] On the basis of the first embodiment above, the first sphere 91 is made of a permanent magnet, and the separator 6 is made of a ferromagnetic material. The first sphere 91 can open the through hole 61 in water and a liquid with a specific gravity greater than 1.

[0031] Since the first sphere 91 is made of permanent magnet material, the first sphere 91 is attracted to the separator 6 made of ferromagnetic material, thereby increasing the sealing performance and preventing the first sphere 91 from moving freely under the washing of the liquid.

[0032] It is worth mentioning that buoyancy compensation can be performed by changing the thickness of the second sphere 92 to reduce gravity, so that the first sphere 91 can float in the oil layer against the magnetic force of the separator 6 .

Embodiment 3

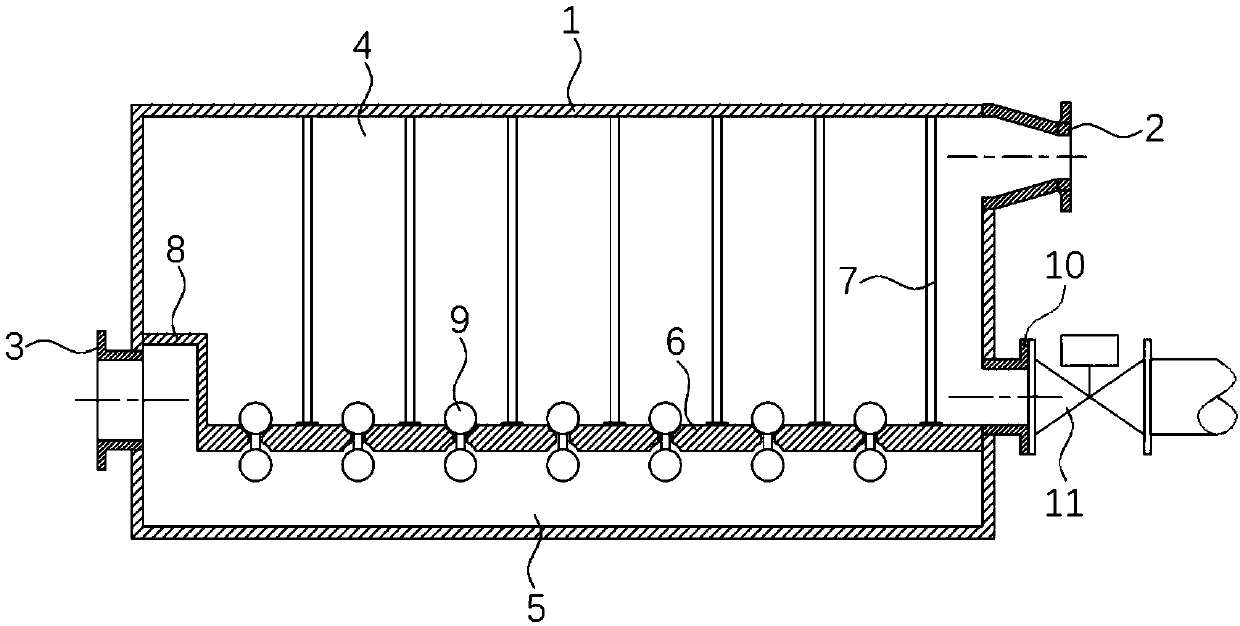

[0034] On the basis of the second embodiment above, a plurality of anti-turbulence rods 7 perpendicular to the two are fixedly connected between the top of the partition 6 and the inner top of the container 1 .

[0035] Preferably, the anti-turbulence rod 7 is located between two adjacent through holes 61 .

[0036] Because the speed of the sewage from the mixed liquid inlet pipe 2 is too fast, the anti-turbulence rod 7 reduces the speed at which the mixed liquid inlet pipe 2 enters the container 1, and the turbulent flow becomes transitional flow or laminar flow under the blocking effect of the anti-turbulence rod 7 On the one hand, it facilitates the stratification of water and oil, and on the other hand, it can also prevent the first ball 91 from being washed and displaced, which can improve the efficiency of sewage treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com