Underground excavated spliced type underpinning structure on lower part of existing building base and construction method thereof

An existing building and assembled technology, which is applied in the direction of building construction, infrastructure engineering, infrastructure repair, etc., can solve the problems of occupying the internal space of the building and affecting the daily use of the building, so as to avoid wet work and shorten construction Period, the effect of enhancing load-carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

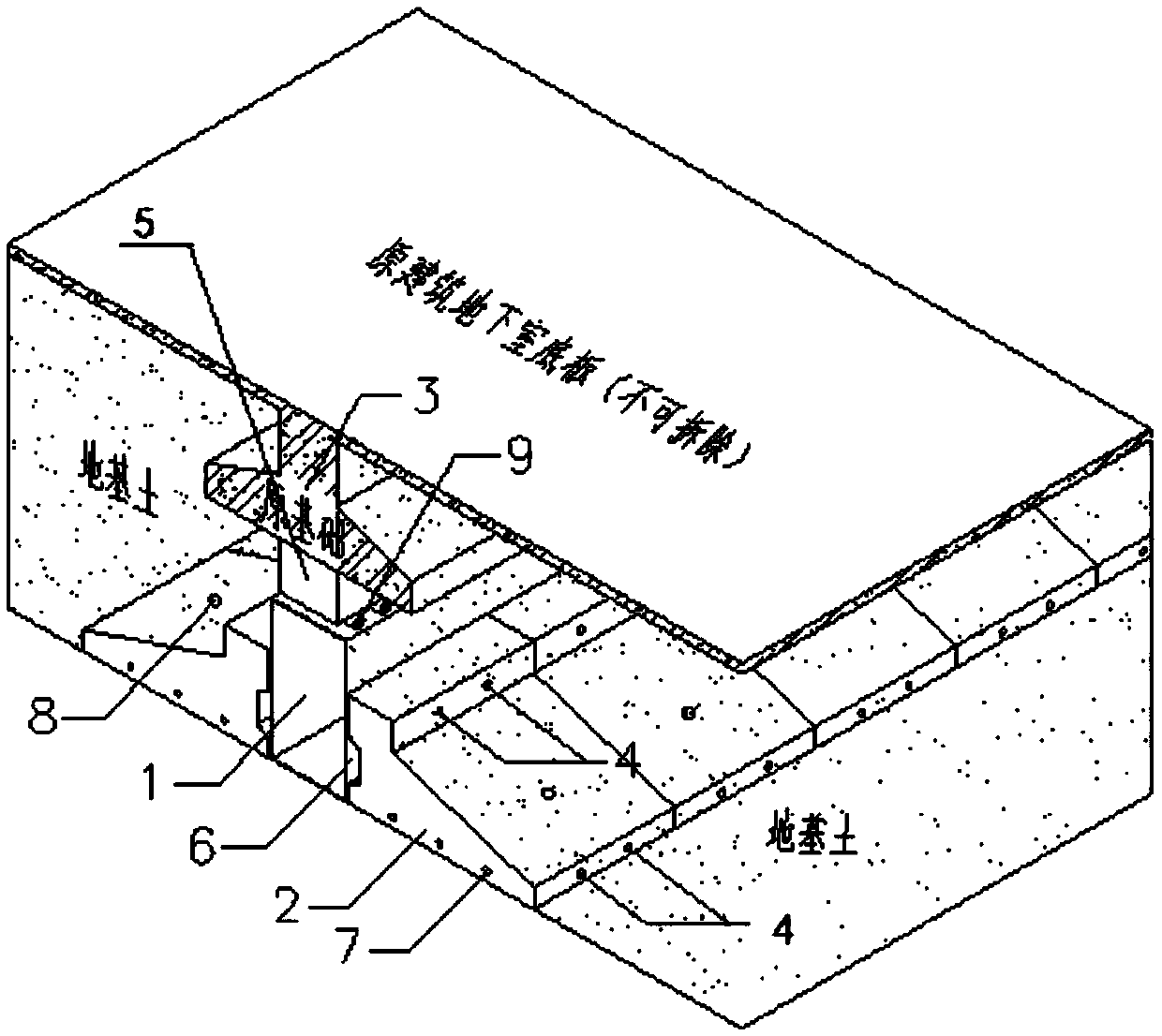

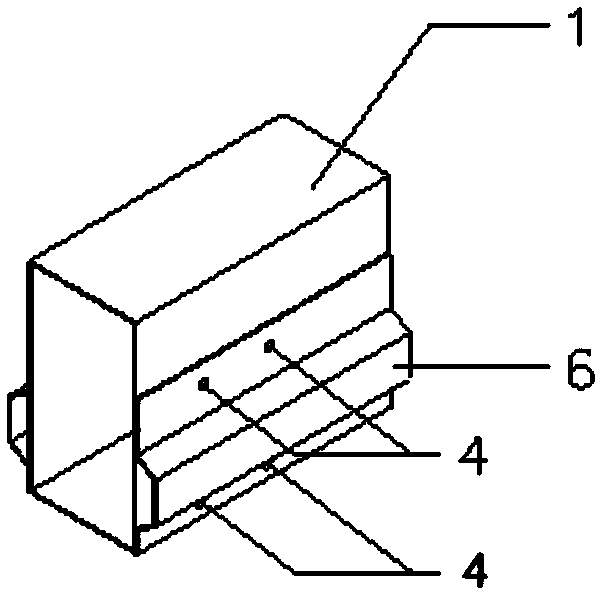

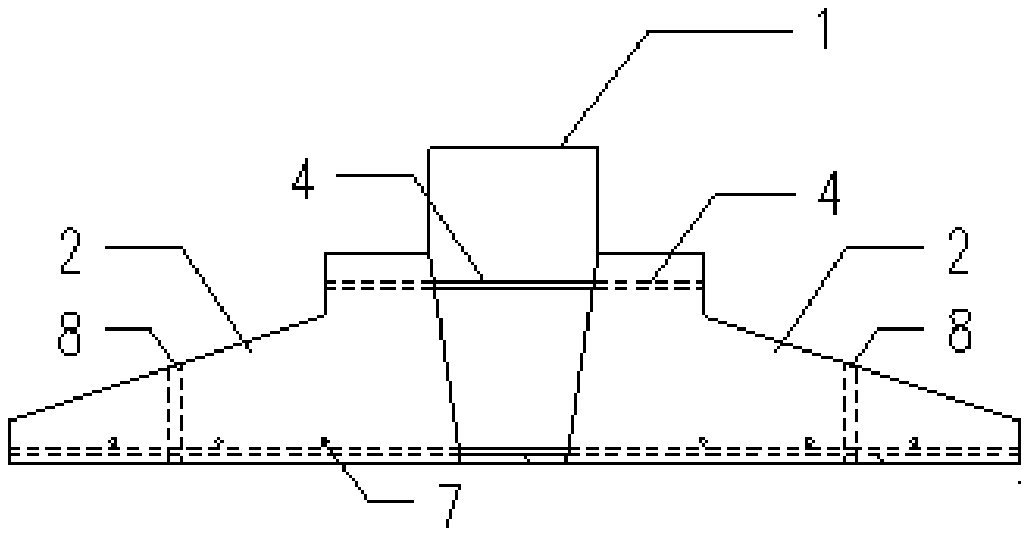

[0035] Such as Figure 1 to Figure 3 As shown, an underpinning assembled underpinning structure under the base of an existing building includes a rectangular steel pipe 1 and a prefabricated component 2. The rectangular steel pipe 1 is located at a certain depth directly below the original foundation 3 on the underside of the building base. A moving roller 9 is arranged on the rectangular steel pipe 1, and an upper joist 5 is installed on the moving roller 9. The spatial dimension of the rectangular steel pipe 1 should meet the needs of workers entering the internal construction operation. The wall thickness of the rectangular steel pipe 1 is more than 10mm, the height of the rectangular steel pipe 1 is more than 1.5m, and the width of the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com