Concrete beam and section steel concrete column anchoring structure and construction method

A technology for concrete columns and concrete beams, applied in building construction, building material processing, construction, etc., can solve problems such as bond splitting damage, and achieve the effects of improving tensile capacity, facilitating construction, and reducing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

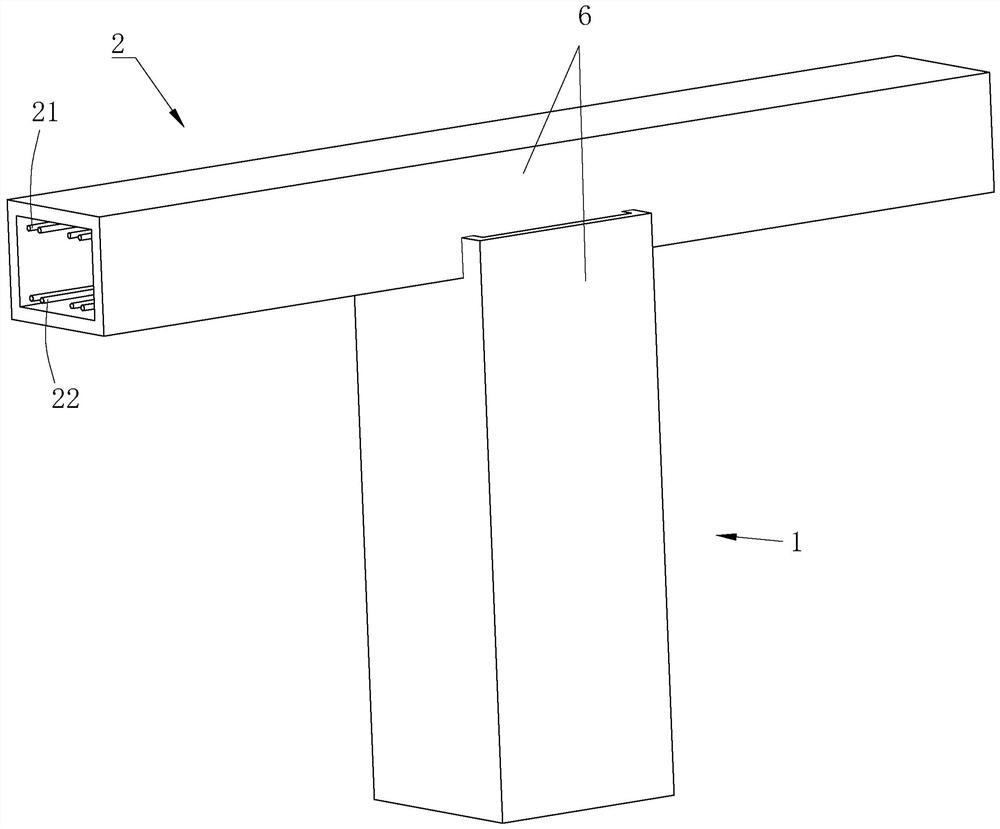

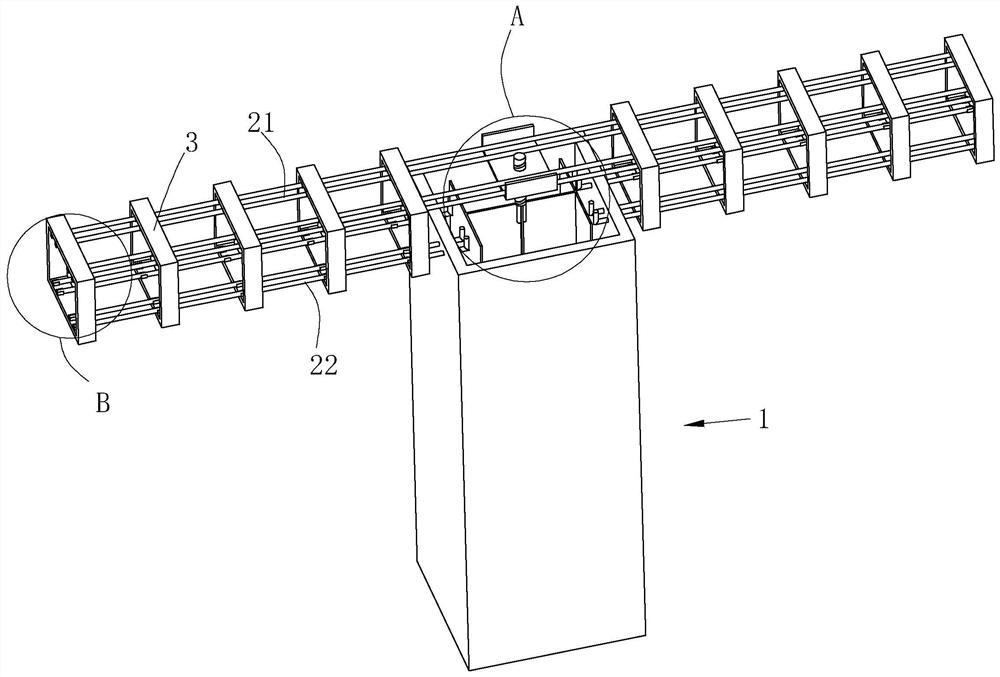

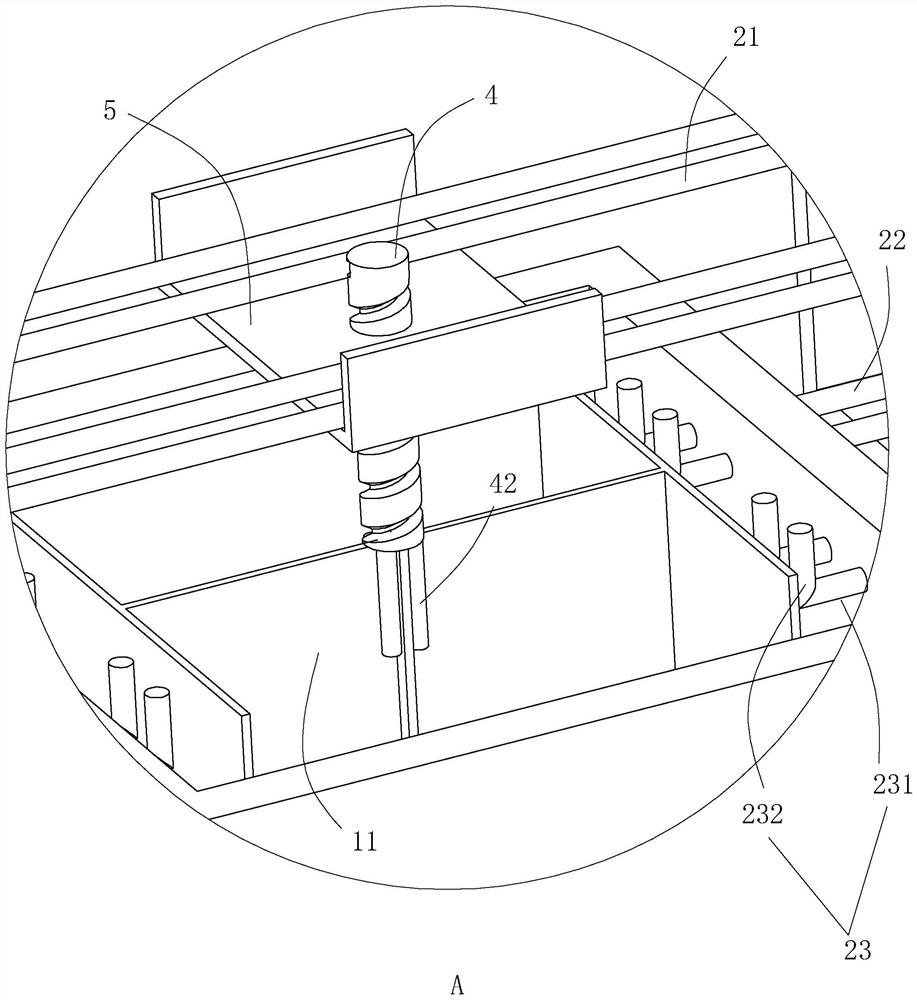

[0047] Such as Figure 1 to Figure 2 As shown, the anchorage structure of a concrete beam and a steel concrete column disclosed by the present invention includes a concrete column 1, a section steel 11 is embedded in the concrete column 1, a concrete beam 2 is connected between adjacent concrete beams 2, and the inner edge of the concrete beam 2 The concrete beam 2 is horizontally buried with an upper through-bar 21 and a lower longitudinal bar 22 , wherein the upper through-bar 21 is located above the lower longitudinal bar 22 . The upper through-bar 21 runs through the upper end of the concrete column 1 , and the height of the upper end of the shaped steel 11 is lower than that of the upper through-bar 21 so that the upper through-bar 21 does not contact the shaped steel 11 .

[0048] Such as image 3 As shown, the end of the lower longitudinal reinforcement 22 close to the concrete column 1 is fixed with a vertically upward curved hook 23, the bending angle of the hook 23 ...

Embodiment 2

[0059] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the bending section 232 is wave-shaped, thereby increasing the bonding area between the bending section 232 and the concrete of the concrete column 1 at the same height, and further The tensile performance of the concrete beam 2 is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com