Prestressed pipe grouting agent

A prestressed pipeline and grouting agent technology, applied in the field of grouting agent preparation, can solve the problems of poor stability, poor fluidity, and high bleeding rate of the grouting agent, and achieve low cost, pollution-free access, and good expansibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

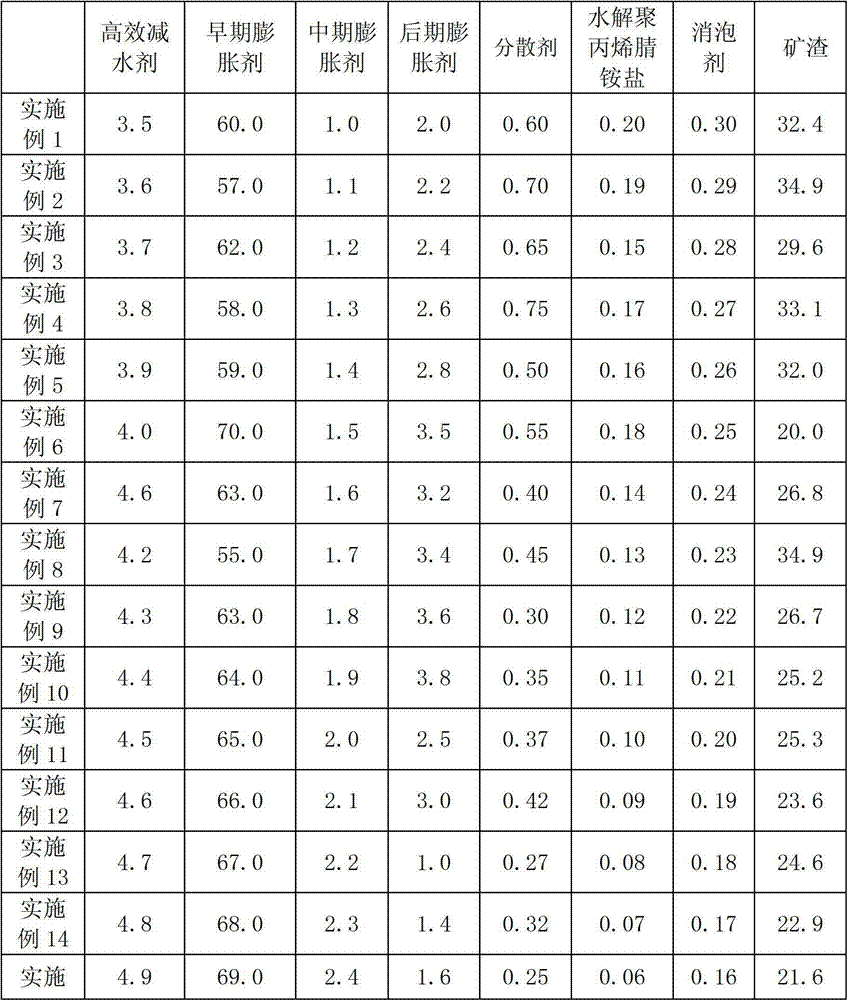

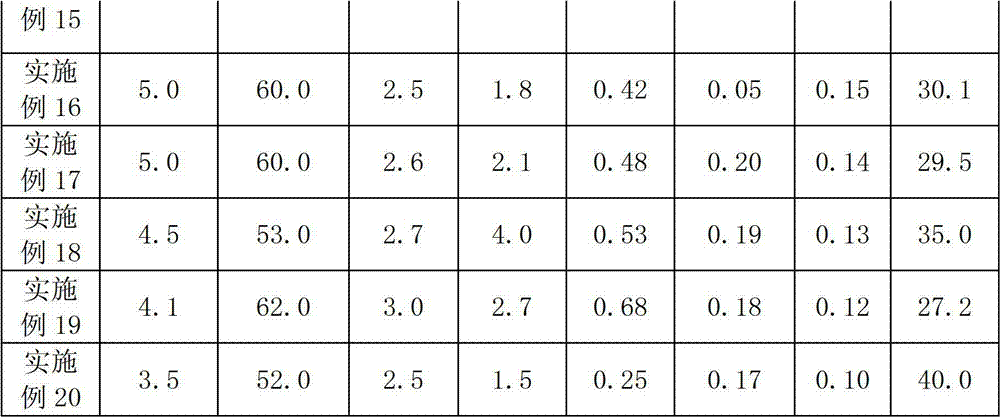

[0029] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

[0030] The invention discloses a prestressed pipeline grouting agent, which comprises the following components and contents:

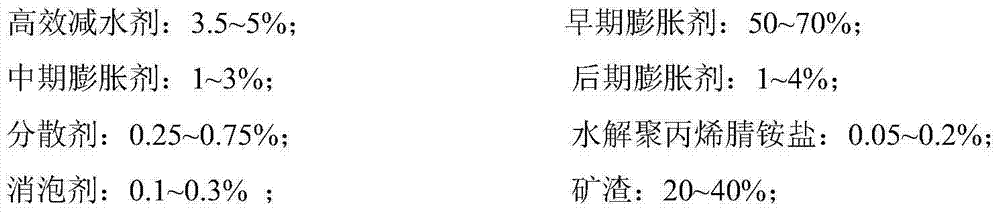

[0031] High-efficiency water reducer: 3.5-5%; early expansion agent: 50-70%;

[0032] Mid-term expansion agent: 1~3%; Post-expansion agent: 1-4%;

[0033] Dispersant: 0.25~0.75%; Hydrolyzed polyacrylonitrile ammonium salt: 0.05~0.2%;

[0034] Defoamer: 0.1-0.3%; Slag: 20-40%.

[0035] Among them, high-efficiency water reducer is an admixture that keeps the cement paste, mortar and concrete workability unchanged and significantly reduces its mixing water consumption; by dispersing cement particles, and forming a water film and a hydrophilic three-dimensional adsorption layer on the surface of the particles, It can significantly increase the strength of concrete, improve the frost resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com