Anchor cable construction method for multi-stage segmental non-continuous pipe drilling in broken ground

A technology of following the pipe drilling and construction method, which is applied in drilling equipment and methods, excavation, earthwork drilling, etc. It can improve the efficiency of extubation, reduce the use of casing, and ensure reliable construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to deepen the understanding of the present invention, reference will be made to Figure 1 to Figure 16 , the embodiments of the present invention are described in detail, the following embodiments are implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

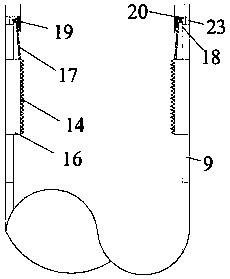

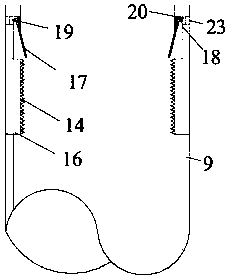

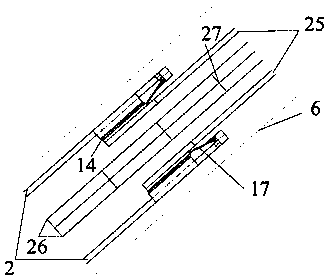

[0045] The drilling depth is 20m, the diameter of the primary casing is 15cm, and the length is 3m, the diameter of the secondary casing is 12cm, and the length is 5m, and the diameter of the third casing is 9cm, and the length is 4m. 7m, the rod body adopts 1860 grade steel strands, the connection strength of a single steel strand is greater than 200kN, and a spacer is set every 2m along the axis of the rod body, and the grouting material is pure cement slurry with a water-cement ratio of 0.45~0.50. The drilling tool adopts TY210, and the eccentric d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap