Energy output system and method applied to urea plant

A technology for urea plant and energy output, which is applied in the direction of pump device, steam engine device, non-variable pump, etc., to achieve the effect of low system investment, high output efficiency and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

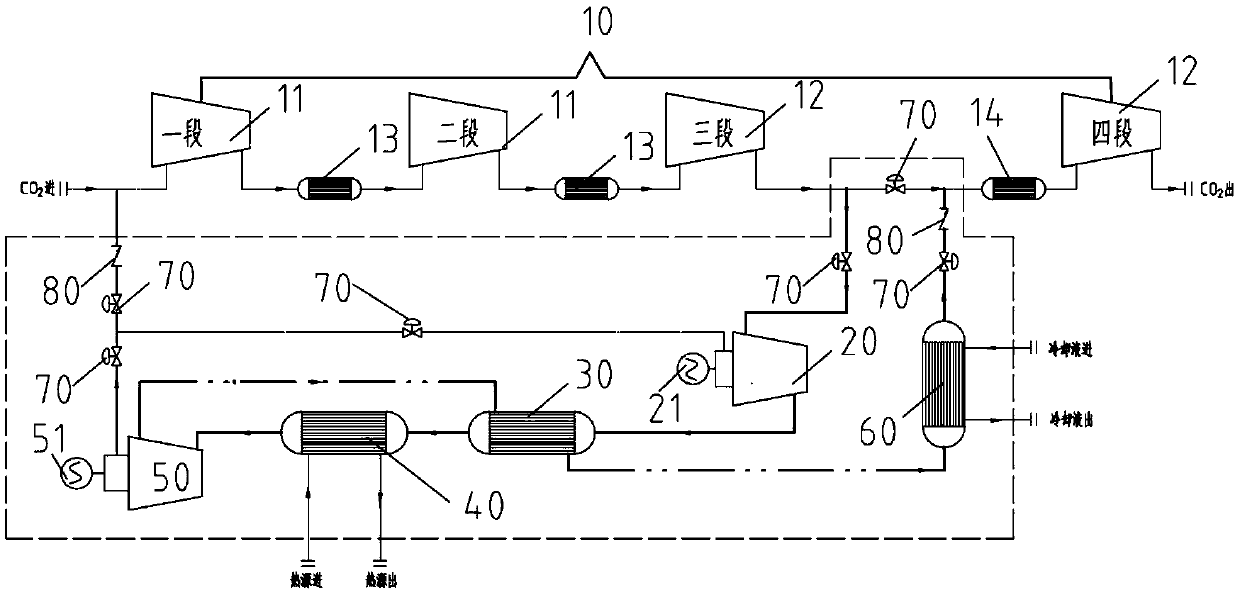

[0025] Embodiment 1: as figure 1 As shown, an energy output system applied to a urea plant, the urea plant includes a carbon dioxide multi-stage centrifugal compressor 10, the multi-stage centrifugal compressor includes several low-pressure sections 11 and several high-pressure sections 12, two adjacent sections There is an intercooler between them, and a subcritical carbon dioxide output pipeline and an input pipeline are arranged between the terminal high-pressure section and the secondary terminal high-pressure section, and the output pipeline is connected to the supercharger 20, the preheater 30, the heating 40 and expander 50, the carbon dioxide gas after the work done by the expander passes through the preheater 30, the cooler 60, the subcritical carbon dioxide input pipeline into the inter-stage cooler, and finally enters the terminal high-pressure section. The present invention utilizes the existing urea synthesis device to realize the Brayton cycle, so as to realize e...

Embodiment 2

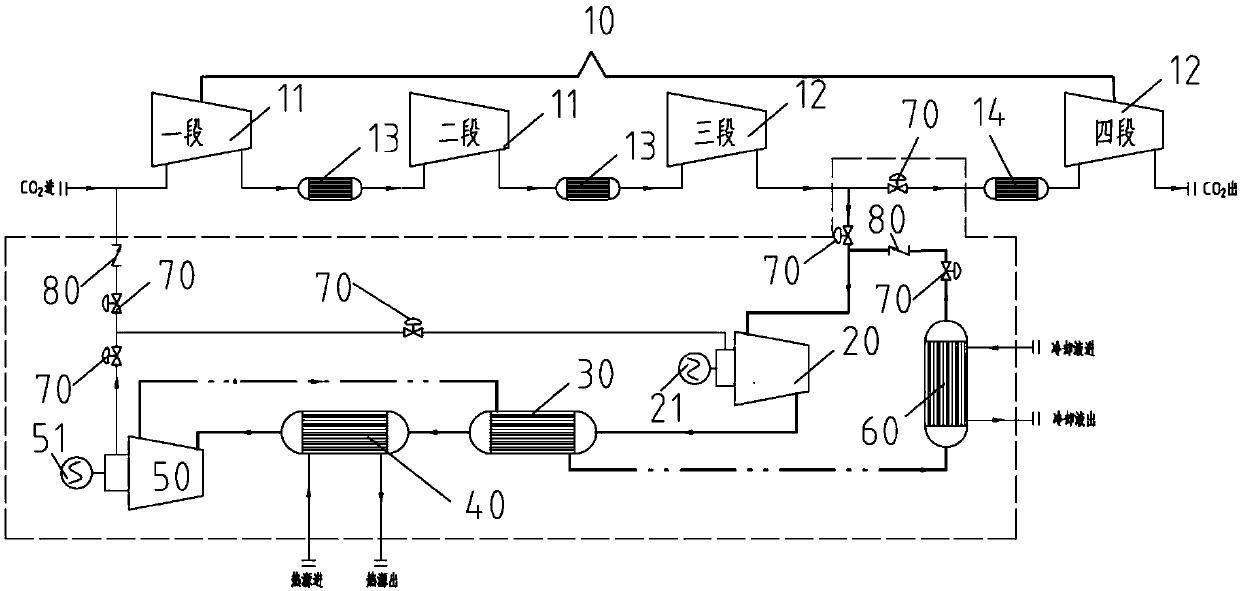

[0029] Embodiment 2: as figure 2 As shown, the only difference from Example 1 is that the carbon dioxide gas after the work done by the expander passes through the preheater 30, the cooler 60, and the subcritical carbon dioxide input pipeline to return to the supercharger 20 for recycling, that is, after the booster After pressurization, the compressor passes through the preheater 30 and the heater 40 and then enters the expander to do work. In this embodiment, after a certain amount of carbon dioxide is extracted from the urea plant, the carbon dioxide gas will no longer return to the urea synthesis system, but will be added in the newly added The system formed by the equipment is recycled, and the urea plant supplements the small amount of carbon dioxide gas lost during the operation of the system of this embodiment through the regulating valve 70.

[0030] Operation process of the present invention: the steps are as follows:

[0031] Step 1: Lead the subcritical carbon diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com