A kind of preparation technology of lithium ion battery conductive agent based on modified graphene

A lithium ion battery and a preparation process technology, which is applied in the field of preparation technology of a lithium ion battery conductive agent based on modified graphene, can solve problems such as poor dispersion effect and poor conductivity, and achieve stable performance, improved conductivity, and combined effect. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

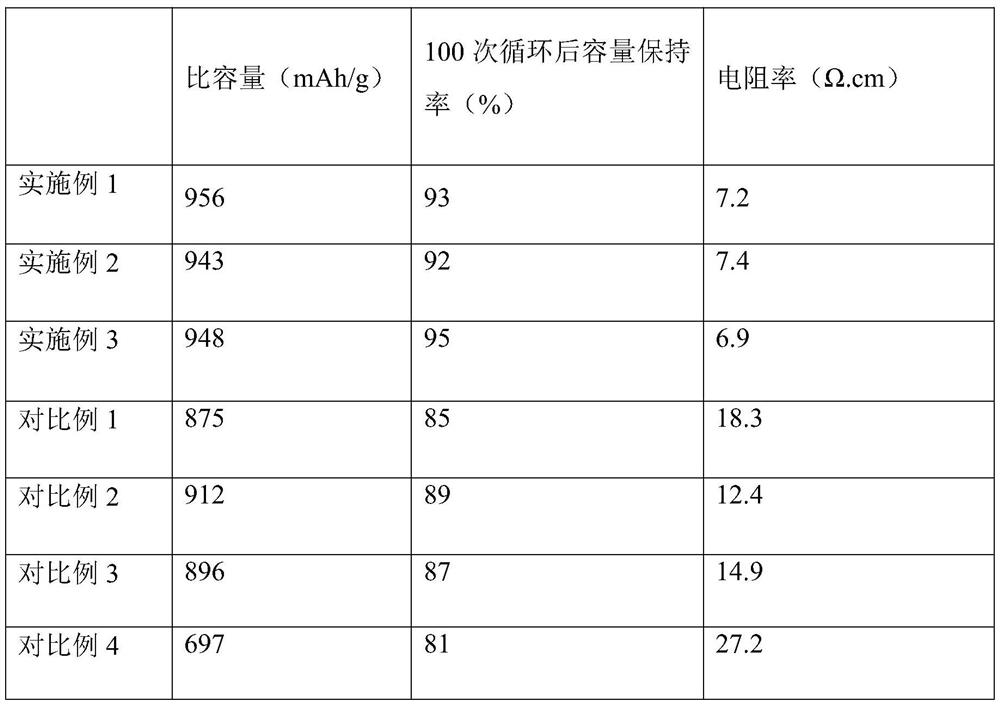

Examples

Embodiment 1

[0026] A kind of lithium-ion battery conductive agent preparation process based on modified graphene of the present embodiment comprises the following steps:

[0027] In step 1, 55 parts of graphene are first activated, then mixed with aluminum-based rare earth liquid according to the weight ratio of 1:1.2 and sent into the high-pressure reactor, and adopt 60 co r Radiation source irradiation treatment, the total radiation dose is 4.0Gy, and the irradiation time is 40min. After the reaction is completed, it is washed twice with deionization, and then the surface is modified, and then it is ready for use;

[0028] Step 2: ultrasonically disperse the spare graphene and 30 parts of ethanol in step 1 for 10 minutes, then add 15 parts of carbon black and 3 parts of functionalized cellulose nanospheres, continue to ultrasonically disperse for 20 minutes, finally add 5 parts of polyaniline, and then Send the mixed solution into a high-speed disperser and stir for 1 hour at a stirrin...

Embodiment 2

[0040] A kind of lithium-ion battery conductive agent preparation process based on modified graphene of the present embodiment comprises the following steps:

[0041] In step 1, 65 parts of graphene are first activated, and then mixed with aluminum-based rare earth liquid according to the weight ratio of 1:1.8 and sent into the high-pressure reactor, and used 60 co r Radiation source irradiation treatment, the total radiation dose is 5.0Gy, and the irradiation time is 50min. After the reaction is completed, it is washed with deionization for 3 times, and then the surface is modified, and then it is ready for use;

[0042] Step 2: ultrasonically disperse the spare graphene and 40 parts of ethanol in step 1 for 20 minutes, then add 25 parts of carbon black and 6 parts of functionalized cellulose nanospheres, continue to ultrasonically disperse for 30 minutes, and finally add 10 parts of polyaniline, and then Send the mixed solution into a high-speed disperser and stir for 2 hou...

Embodiment 3

[0054] A kind of lithium-ion battery conductive agent preparation process based on modified graphene of the present embodiment comprises the following steps:

[0055] In step 1, 60 parts of graphene are activated first, then mixed with aluminum-based rare earth liquid according to the weight ratio of 1:1.5 and sent into the high-pressure reactor, and adopt 60 co r Radiation source irradiation treatment, the total radiation dose is 4.5Gy, and the irradiation time is 45min. After the reaction is completed, it is washed with deionization for 3 times, and then the surface is modified, and then it is ready for use;

[0056] Step 2: ultrasonically disperse the spare graphene and 35 parts of ethanol in step 1 for 15 minutes, then add 20 parts of carbon black and 4.5 parts of functionalized cellulose nanospheres, continue to ultrasonically disperse for 25 minutes, and finally add 7.5 parts of polyaniline, and then Send the mixture into a high-speed disperser and stir for 1.5 hours at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com