Preparation method of graphene-based composite conductive and thermally conductive fiber material with imitation shell structure

A graphene-based, composite conductive technology, which is applied to the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve the problems affecting the electrical and thermal conductivity, and the electrical and thermal conductivity is less involved, so as to achieve the improvement of electrical and thermal conductivity and increase the electrical conductivity. Effects of Conduction and Thermal Conduction Channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Using expanded graphite as raw material, graphene oxide aqueous dispersion was prepared by modified Hummers method.

[0036] Add a certain quality of plant raw materials into a 1:1 mixed solution of concentrated sulfuric acid and deionized water, heat and hydrolyze at 65°C for 1.5h, stop heating and add deionized water to dilute, let stand overnight, remove the supernatant, and centrifuge to wash , dialysis, and ultrasound to obtain a cellulose nanocrystal solution.

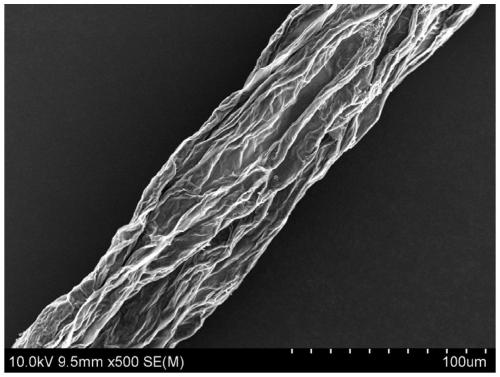

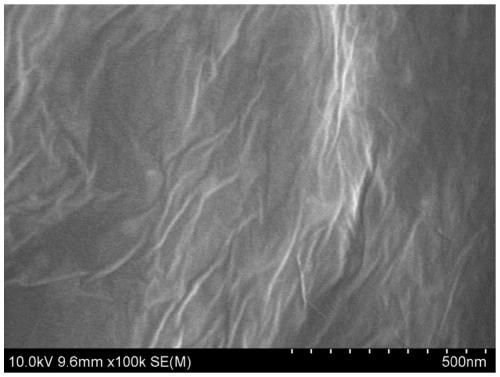

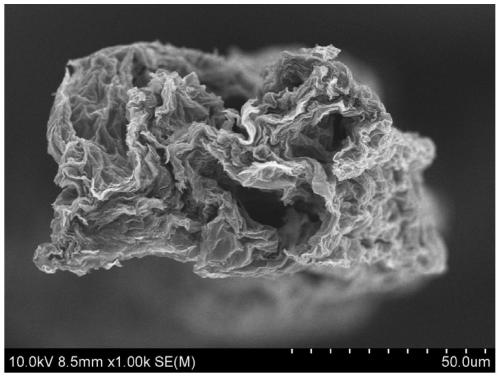

[0037] The prepared graphene oxide aqueous dispersion, cellulose nanocrystal solution, and carbon quantum dot solution are mixed with a solute mass ratio of 1:1:0.2, stirred, concentrated, and prepared into a pre-spinning solution. The pre-spinning solution is placed in isopropanol, a spinning coagulation liquid, and wet-spun at a speed of 0.5 mm / min to obtain graphene-based composite fibers or fabrics. Anneal and reduce the obtained fiber or fabric at a high temperature of 1500°C for 2 hours.

[0038] ...

Embodiment 2

[0048] Using expanded graphite as raw material, graphene oxide aqueous dispersion was prepared by modified Hummers method.

[0049] Add a certain quality of plant raw materials into a 1:1 mixed solution of concentrated sulfuric acid and deionized water, heat and hydrolyze at 65°C for 1.5h, stop heating and add deionized water to dilute, let stand overnight, remove the supernatant, and centrifuge to wash , dialysis, and ultrasound to obtain a cellulose nanocrystal solution.

[0050] The prepared graphene oxide aqueous dispersion, cellulose nanocrystal solution, and carbon quantum dot solution are mixed with a solute mass ratio of 1.6:0.4:0.2, stirred, concentrated, and prepared into a pre-spinning solution. The pre-spinning solution is placed in isopropanol, a spinning coagulation liquid, and wet-spun at a speed of 0.5 mm / min to obtain graphene-based composite fibers or fabrics. Anneal and reduce the obtained fiber or fabric at a high temperature of 1500°C for 2 hours.

Embodiment 3

[0052] Using expanded graphite as raw material, graphene oxide aqueous dispersion was prepared by modified Hummers method.

[0053] Add a certain quality of plant raw materials into a 1:1 mixed solution of concentrated sulfuric acid and deionized water, heat and hydrolyze at 65°C for 1.5h, stop heating and add deionized water to dilute, let stand overnight, remove the supernatant, and centrifuge to wash , dialysis, and ultrasound to obtain a cellulose nanocrystal solution.

[0054] The prepared graphene oxide aqueous dispersion, cellulose nanocrystal solution, and carbon quantum dot solution are mixed with a solute mass ratio of 0.4:1.6:0.2, stirred, concentrated, and prepared into a pre-spinning solution. The pre-spinning solution is placed in isopropanol, a spinning coagulation liquid, and wet-spun at a speed of 0.5 mm / min to obtain graphene-based composite fibers or fabrics. Anneal and reduce the obtained fiber or fabric at a high temperature of 1500°C for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com