Method for removing teeth of sea mushroom

A sea ling mushroom detooth technology, applied in the field of hai ling mushroom detoxification, can solve the problems of hindering the development of hai ling mushroom products, reducing the added value of hai ling mushroom products, and low operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for detoxification of Hailing mushroom, which comprises the following steps:

[0023] (1) Raw material processing: thaw the frozen Hailing mushroom blocks under running water at 4°C to a semi-thawed state.

[0024] (2) Rolling treatment: Carry out rolling treatment on the Hailing mushroom in the semi-thawed state, the rolling pressure is 0.5MPa, and the time is 15-30s;

[0025] (3) Ultrasonic treatment: Ultrasonic treatment was carried out on the Hailing mushroom after the rolling treatment, the ultrasonic power was 400W, the ultrasonic frequency was 35KHz, the ultrasonic time was 30min, and the ultrasonic temperature was 4°C.

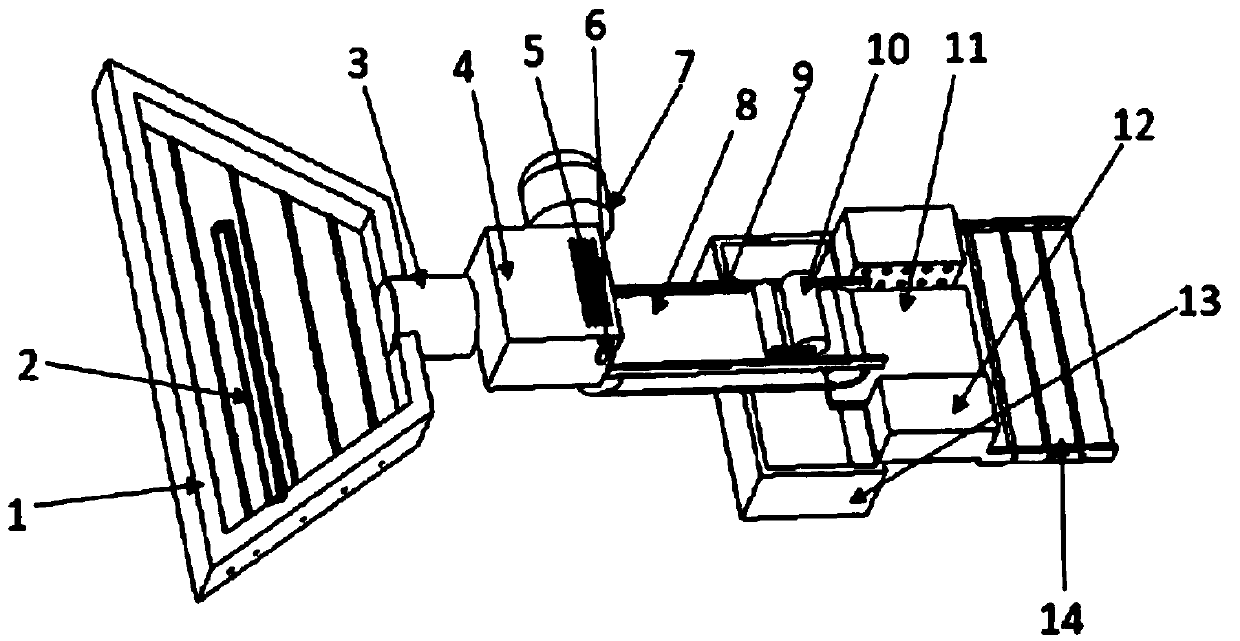

[0026] (4) Detooth removal by rolling: use a detooth device to process the Hailing mushroom after ultrasonic treatment. Such as figure 1 As shown, the gear removal device includes a feed bin 1, a siphon pipe 3, a condenser 4, a conveyor belt 8, a rolling wheel set 10, a cleaning platform 11, and a discharge bin 14, and one end of the ...

Embodiment 2

[0034] A method for detoxification of Hailing mushroom, which comprises the following steps:

[0035] (1) Raw material processing: thaw the frozen Hailing mushroom blocks under running water at 4°C to a semi-thawed state.

[0036] (2) Rolling treatment: Carry out rolling treatment on the Hailing mushroom in the semi-thawed state, the rolling pressure is 1MPa, and the time is 20s;

[0037] (3) Ultrasonic treatment: Ultrasonic treatment was carried out on the sea ling mushroom after the rolling treatment, the ultrasonic power was 800W, the ultrasonic frequency was 40KHz, the ultrasonic time was 40min, and the ultrasonic temperature was 10°C.

[0038] (4) Detooth removal by rolling: use a detooth device to process the Hailing mushroom after ultrasonic treatment. Such as figure 1 As shown, the gear removal device includes a feed bin 1, a siphon pipe 3, a condenser 4, a conveyor belt 8, a rolling wheel set 10, a cleaning platform 11, and a discharge bin 14, and one end of the sip...

Embodiment 3

[0046] A method for detoxification of Hailing mushroom, which comprises the following steps:

[0047] (1) Raw material processing: thaw the frozen Hailing mushroom blocks under running water at 4°C to a semi-thawed state.

[0048] (2) Rolling treatment: Carry out rolling treatment on the Hailing mushroom in the semi-thawed state, the rolling pressure is 0.7MPa, and the time is 30s;

[0049] (3) Ultrasonic treatment: Ultrasonic treatment was carried out on the sea ling mushroom after the rolling treatment, the ultrasonic power was 600W, the ultrasonic frequency was 37KHz, the ultrasonic time was 35min, and the ultrasonic temperature was 7°C.

[0050] (4) Detooth removal by rolling: use a detooth device to process the Hailing mushroom after ultrasonic treatment. Such as figure 1 As shown, the gear removal device includes a feed bin 1, a siphon pipe 3, a condenser 4, a conveyor belt 8, a rolling wheel set 10, a cleaning platform 11, and a discharge bin 14, and one end of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com