Acid-resistant cream

An acid-resistant and butter-resistant technology, which is applied to the preservation of edible oil/fat containing fatty acid esters, edible oil/fat components, and edible oil/fat finished products. and other problems, to achieve the effect of prolonging the storage time, increasing the foaming rate, and enhancing the acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

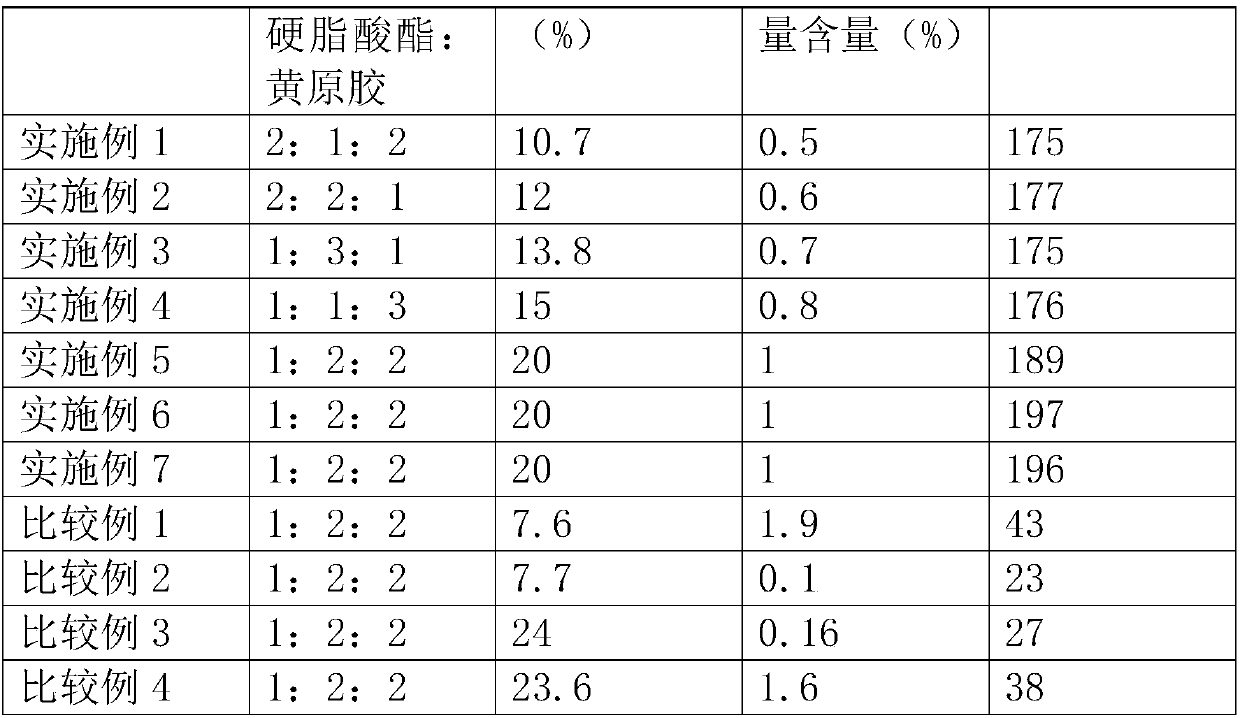

Embodiment 1

[0059] A kind of sour cream, comprising the following components in parts by mass:

[0060] Drinking water 40kg; Milk fat 40kg; Refined vegetable oil 11kg; Glucose 5kg; Glucose syrup 5kg; Sodium caseinate 0.5kg; , xanthan gum 0.2kg; salt 1kg.

[0061] Sour cream is prepared as follows:

[0062] S1, mix evenly, as follows:

[0063] Add 40kg of drinking water to a 150L stirred tank, stir at a speed of 120r / min, add 40kg of milk fat, 11kg of refined vegetable oil, 5kg of glucose, 5kg of glucose syrup, 0.5kg of sodium caseinate, 0.2kg of soybean lecithin, Triglycerol monostearate 0.1kg, xanthan gum 0.2kg, salt 1kg, stir well, obtain mixture;

[0064] S2, emulsification sterilization, specifically as follows:

[0065] Put the mixture obtained in S1 into the emulsifier for emulsification, then pass the emulsified mixture through the sterilizer, and use steam to sterilize, control the temperature of the steam to 70°C, and control the sterilization time to 8 minutes;

[0066] S3,...

Embodiment 2

[0073] A kind of sour cream, comprising the following components in parts by mass:

[0074] Drinking water 48kg; Milk fat 45kg; Refined vegetable oil 15kg; Glucose 7kg; Glucose syrup 6kg; Sodium caseinate 0.7kg; , xanthan gum 0.16kg; salt 1.5kg.

[0075] Sour cream is prepared as follows:

[0076] S1, mix evenly, as follows:

[0077] Add 48kg of drinking water to a 150L stirred tank, stir at a speed of 120r / min, add milk fat 45kg, refined vegetable oil 15kg, glucose 7kg, glucose syrup 6kg, sodium caseinate 0.7kg, soybean lecithin 0.32kg, Triglycerol monostearate 0.32kg, xanthan gum 0.16kg, salt 1.5kg, stir well, obtain mixture;

[0078] S2, emulsification sterilization, specifically as follows:

[0079] Put the mixture obtained in S1 into an emulsifier for emulsification, then pass the emulsified mixture through a sterilizer, and use steam to sterilize, control the temperature of the steam to 80°C, and control the sterilization time to 7 minutes;

[0080] S3, homogeneous,...

Embodiment 3

[0087] A kind of sour cream, comprising the following components in parts by mass:

[0088] Drinking water 55kg; Milk fat 50kg; Refined vegetable oil 20kg; Glucose 8kg; Glucose syrup 7kg; Sodium caseinate 1kg; Raw gum 0.2kg; salt 2kg.

[0089] Sour cream is prepared as follows:

[0090] S1, mix evenly, as follows:

[0091] Add 55kg of drinking water into a 150L stirring tank, stir at a speed of 120r / min, add 50kg of milk fat, 20kg of refined vegetable oil, 8kg of glucose, 7kg of glucose syrup, 1kg of sodium caseinate, 0.2kg of soybean lecithin, and three 0.6kg of polyglycerol monostearate, 0.2kg of xanthan gum, and 2kg of salt were stirred evenly to obtain a mixture;

[0092] S2, emulsification sterilization, specifically as follows:

[0093] Put the mixture obtained in S1 into the emulsifier for emulsification, then pass the emulsified mixture through the sterilizer, and use steam to sterilize, control the temperature of the steam to 90°C, and control the sterilization ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com