Semiconductor wafer grinding device with cleaning function

A grinding device and cleaning device technology, which is applied in the direction of grinding devices, semiconductor/solid-state device manufacturing, grinding machine tools, etc., can solve the problems that affect the service life of grinding discs, cannot handle sludge, and fix wafers, etc., so as to improve the service life, Easy to disassemble and contribute to the effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

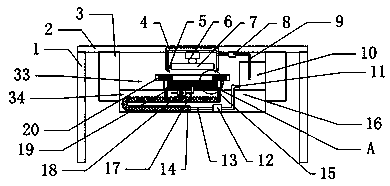

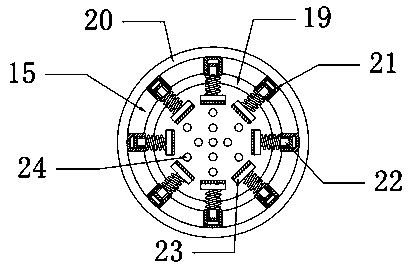

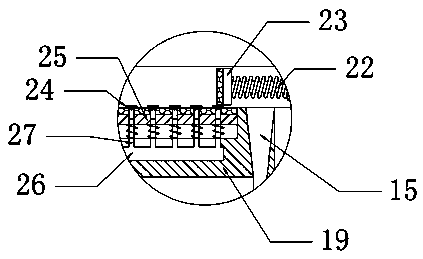

[0026] see Figure 1~4 , in an embodiment of the present invention, a semiconductor wafer grinding device with a cleaning function includes a support rod 1, a top plate 2, a cleaning device 16 and a fixing device 33, and support rods 1 are provided on both sides of the bottom of the top plate 2, and the The support rod 1 is fixedly connected with the top plate 2, the inner side of the support rod 1 is provided with a connecting rod 3 fixedly connected with the top plate 2, the inner side of the connecting rod 3 is provided with a fixing seat 34, and the top of the fixing seat 34 is provided with a fixing device 33 , the upper side of the fixing device 33 is provided with a motor 6, the motor 6 is fixedly connected to the top plate 2, the output end of the lower side of the motor 6 is connected to the grinding disc 7, and the outer side of the grinding disc 7 is provided with a cleaning device 16, so The cleaning device 16 is fixedly connected with the fixing base 34 .

[0027...

Embodiment 2

[0031] A grinding device, comprising the semiconductor wafer grinding device with cleaning function described in Embodiment 1.

[0032] The semiconductor wafer grinding device with cleaning function can realize longitudinal absorption and fixation of the wafer by setting the first fixing block 19, and can carry out lateral extrusion and fixing of the wafer by setting the second fixing block 20, effectively reducing the The circle may slip during grinding. The coarse grinding teeth 30 and the fine grinding teeth 31 are made of diamond, which can improve the service life of the grinding teeth. By setting the coarse grinding teeth 30 and the fine grinding teeth 31, the grinding disc can be used Coarse grinding can also be finely ground, which is conducive to improving the grinding quality. By setting the elbow 14, the fine dust generated during the grinding process can be absorbed, so that water resources can be recycled. By setting the cleaning device 16, it can be cleaned during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com