Efficient prefabricated concrete shield segment steam-curing kiln and application method thereof

A technology of prefabricated concrete and shield segment, which is applied in the direction of manufacturing tools, auxiliary forming equipment, ceramic forming machines, etc., can solve problems such as insufficient resting time, poor production quality of segments, and irregular shape of the outer arc surface, etc., to achieve The effect of prolonging resting time, significant economic effect, and improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

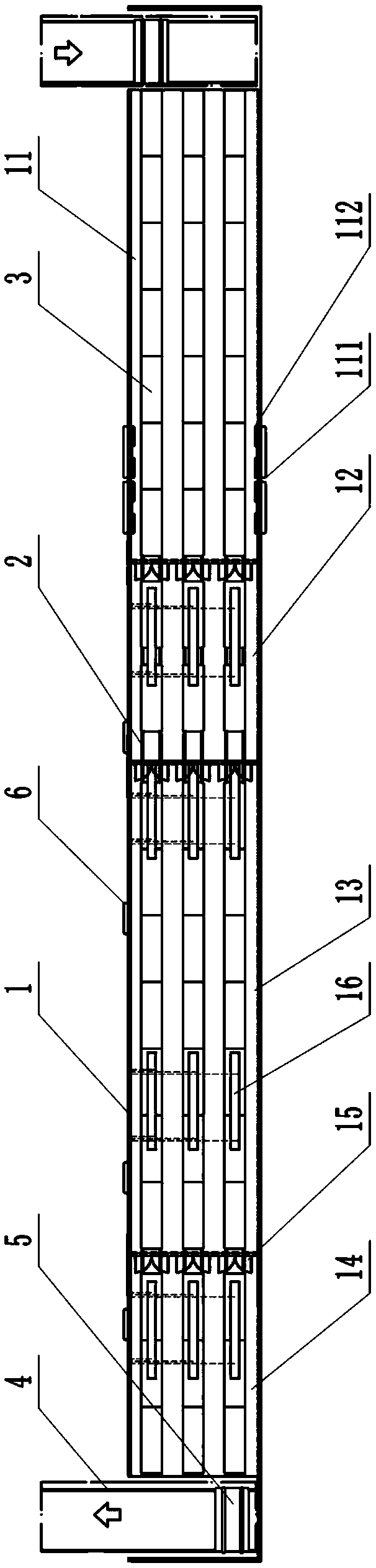

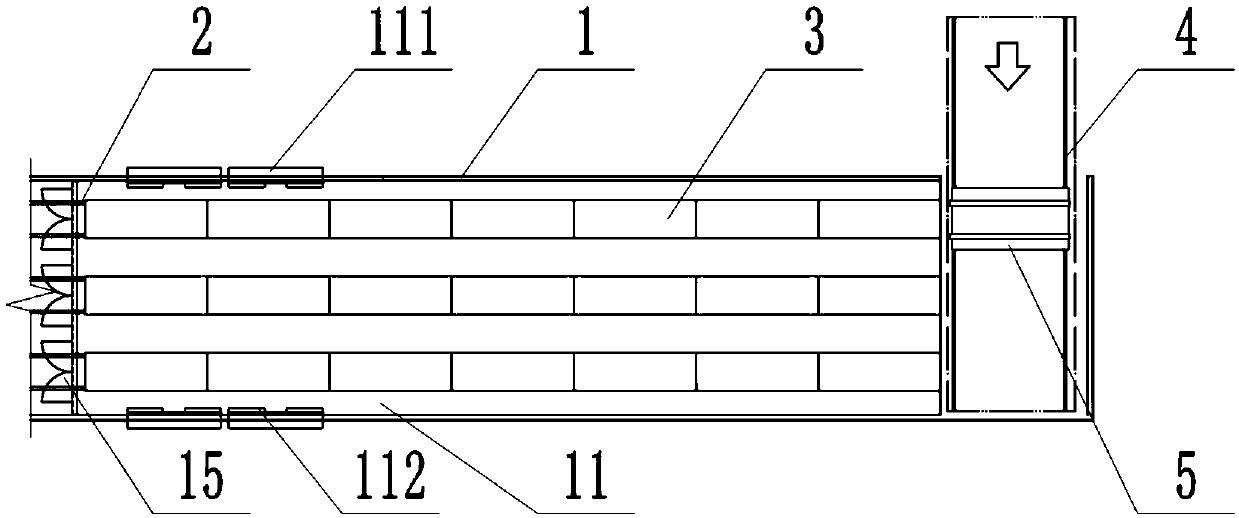

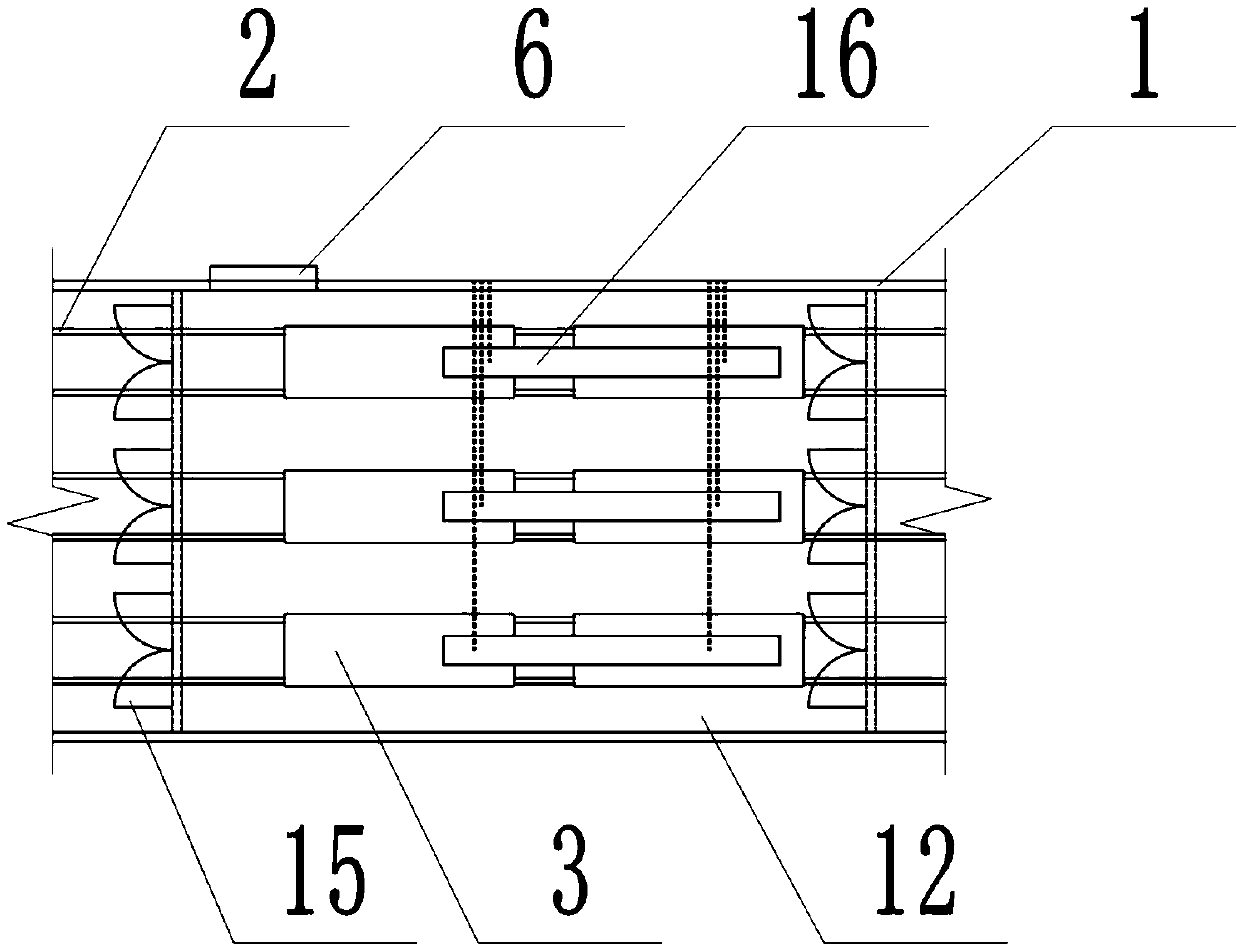

[0042] A high-efficiency prefabricated concrete shield segment steam-curing cellar, comprising a kiln body 1 arranged in a straight line, inside the kiln body 1 there are several maintenance tracks 2 along the kiln body 1, and on the maintenance track 2 there are several maintenance tracks 2 for curing The maintenance vehicle 3 driving on the rail 2 and carrying the segment mold, the entrance and exit of the kiln body 1 is provided with a ferry rail 4, and the ferry rail 4 is provided with a ferry vehicle 5 for driving on the ferry rail 4 and transporting the maintenance vehicle 3 ,

[0043]The interior of the kiln body 1 includes a resting heat preservation area 11, a steaming heating area 12, a steaming constant temperature area 13, and a steaming cooling area 14 from the entrance to the exit, and the adjacent areas are separated by insulation walls. Passing place is all provided with the spring door 15 that is convenient to maintenance car 3 to pass through, and the surface...

Embodiment 2

[0055] A high-efficiency prefabricated concrete shield segment steam-curing cellar, comprising a kiln body 1 arranged in a straight line, inside the kiln body 1 there are several maintenance tracks 2 along the kiln body 1, and on the maintenance track 2 there are several maintenance tracks 2 for curing The maintenance vehicle 3 driving on the rail 2 and carrying the segment mold, the entrance and exit of the kiln body 1 is provided with a ferry rail 4, and the ferry rail 4 is provided with a ferry vehicle 5 for driving on the ferry rail 4 and transporting the maintenance vehicle 3 ,

[0056] The interior of the kiln body 1 includes a resting heat preservation area 11, a steaming heating area 12, a steaming constant temperature area 13, and a steaming cooling area 14 from the entrance to the exit, and the adjacent areas are separated by insulation walls. Passing place is all provided with the spring door 15 that is convenient to maintenance car 3 to pass through, and the surfac...

Embodiment 3

[0068] A high-efficiency prefabricated concrete shield segment steam-curing cellar, comprising a kiln body 1 arranged in a straight line, inside the kiln body 1 there are several maintenance tracks 2 along the kiln body 1, and on the maintenance track 2 there are several maintenance tracks 2 for curing The maintenance vehicle 3 driving on the rail 2 and carrying the segment mold, the entrance and exit of the kiln body 1 is provided with a ferry rail 4, and the ferry rail 4 is provided with a ferry vehicle 5 for driving on the ferry rail 4 and transporting the maintenance vehicle 3 ,

[0069] The interior of the kiln body 1 includes a resting heat preservation area 11, a steaming heating area 12, a steaming constant temperature area 13, and a steaming cooling area 14 from the entrance to the exit, and the adjacent areas are separated by insulation walls. Passing place is all provided with the spring door 15 that is convenient to maintenance car 3 to pass through, and the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com