Fly ash gas-entraining product synergist and preparation method thereof

A technology of synergist and fly ash, which is applied in the field of synergist and its preparation of fly ash gas-entraining products, can solve the problems of complex production process and the great influence of raw materials on finished products, and achieve the improvement of product strength and its Uniformity, improving appearance quality, and improving the effect of product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

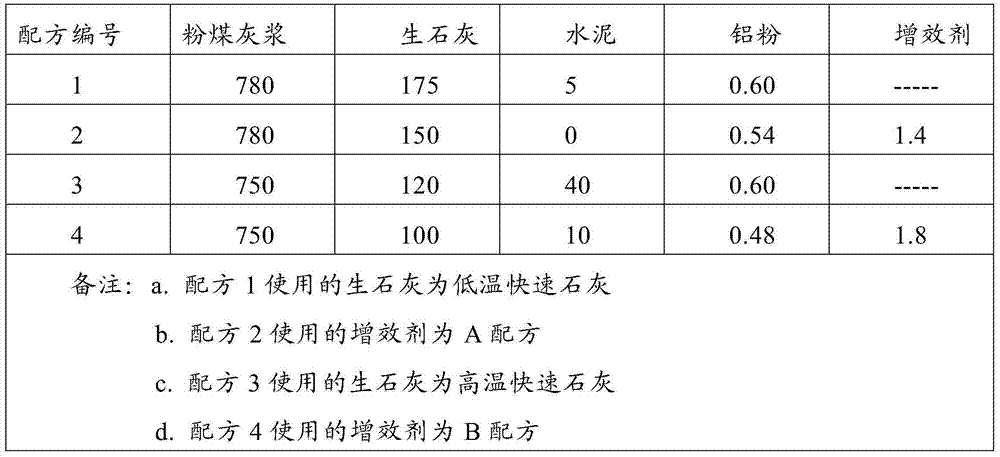

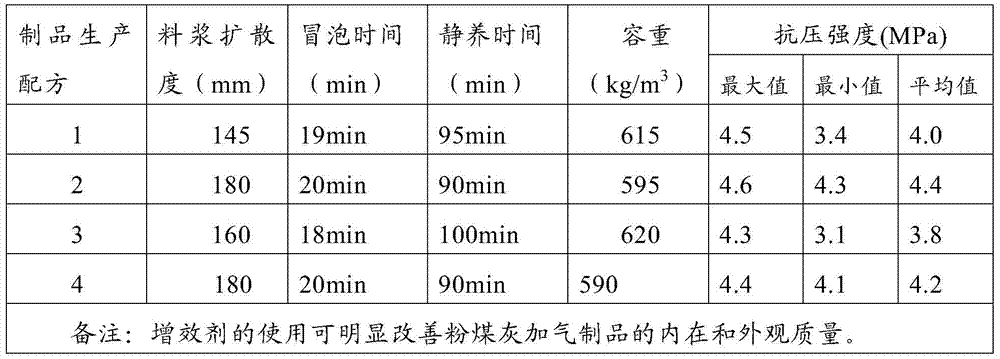

Examples

Embodiment 1

[0026] The fly ash gas-entraining product synergist of the present invention is compounded by the following raw materials:

[0027] HS-109 polycarboxylate superplasticizer: 13.0%;

[0028] Sodium carbonate: 2.0%;

[0029] Sodium tripolyphosphate: 4.0%;

[0030] Self-made modifier: 3.5%;

[0031] Tap water: 77.5%;

[0032] According to the above proportions, put sodium tripolyphosphate into tap water, and after stirring evenly and completely dissolved, add sodium carbonate, polycarboxylate high-efficiency water reducer, and self-made modifier, and then fully stir evenly.

[0033] Preparation method of self-made modifier:

[0034] (1). Base material preparation: Stir triethanolamine, oleic acid, and water at a mass ratio of 1:3:36 for 5 minutes, and keep the temperature at 20°C for about 1 hour;

[0035] (2.) Add triethanolamine having the same quality as the base material and stir for 10 minutes;

[0036] (3.) Add ethylene glycol with the same quality as the base material...

Embodiment 2

[0038] The fly ash gas-entraining product synergist of the present invention is compounded by the following raw materials:

[0039] TC-PCA type polycarboxylate superplasticizer: 15.5%;

[0040] Sodium carbonate: 3.0%;

[0041] Sodium tripolyphosphate: 5.0%;

[0042] Self-made modifier: 5.0%;

[0043] Tap water: 71.5%;

[0044] The preparation method of self-made modifier and synergist is as in Example 1.

Embodiment 3

[0046] The fly ash gas-entraining product synergist of the present invention is compounded by the following raw materials:

[0047] TC-PCA type polycarboxylate superplasticizer: 18.0%;

[0048] Sodium carbonate: 4.0%;

[0049] Sodium tripolyphosphate: 6.0%;

[0050] Self-made modifier: 6.5%;

[0051] Tap water: 65.5%;

[0052] The preparation method of self-made modifier and synergist is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com