Fiber composite and manufacturing method thereof

A technology of fiber composite materials and fibers, which is applied in the field of fiber composite materials with vibration-controlling properties and its manufacturing method, and can solve the problems of overall material rigidity and strength reduction, insufficient vibration-control reduction ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

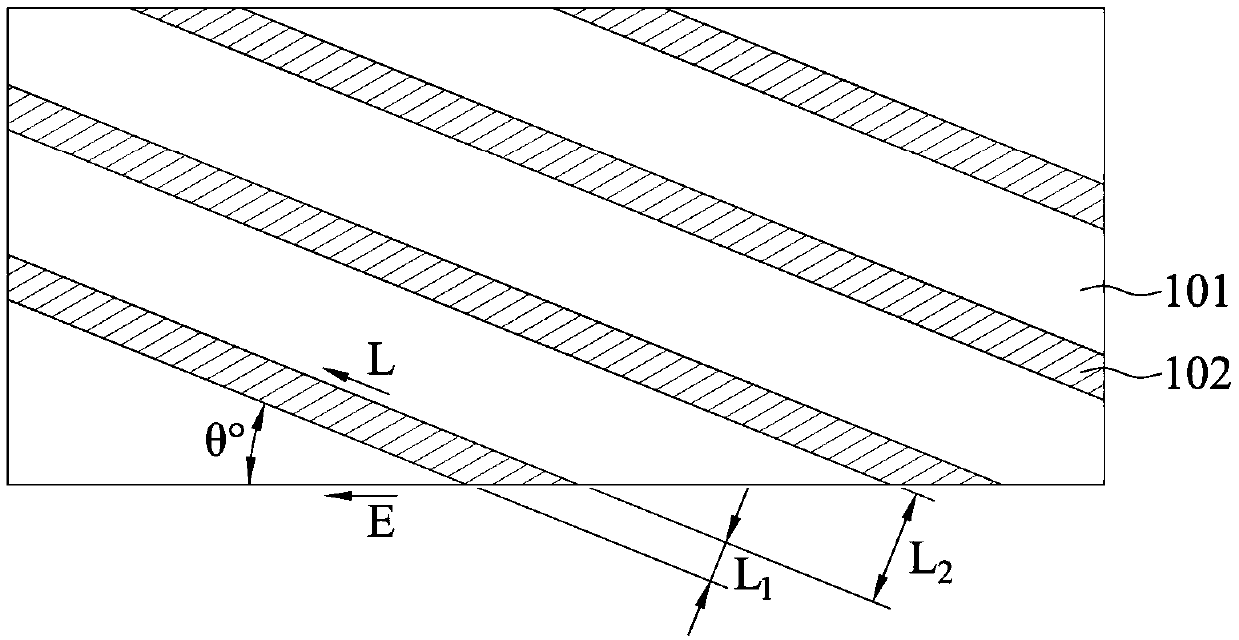

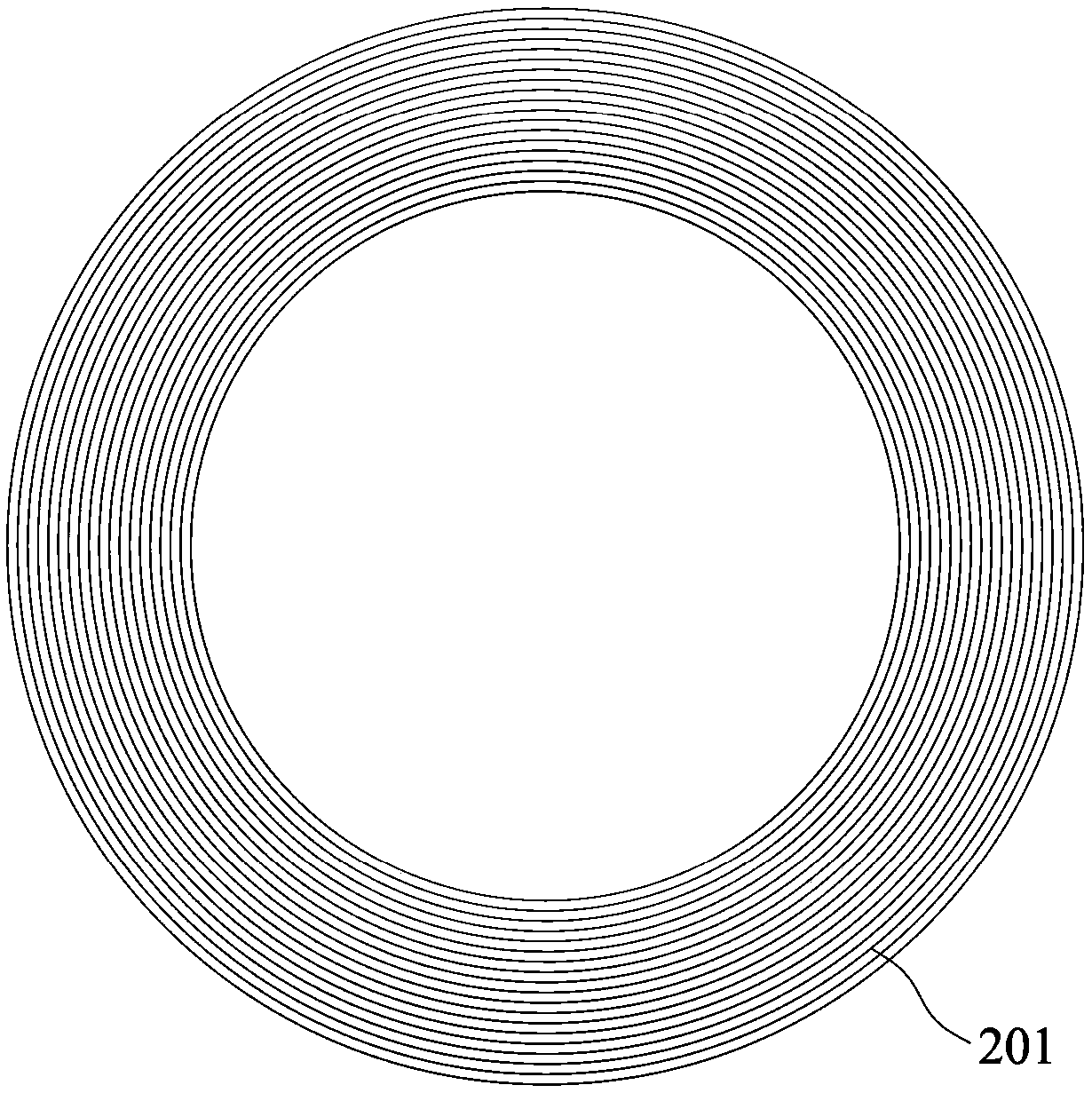

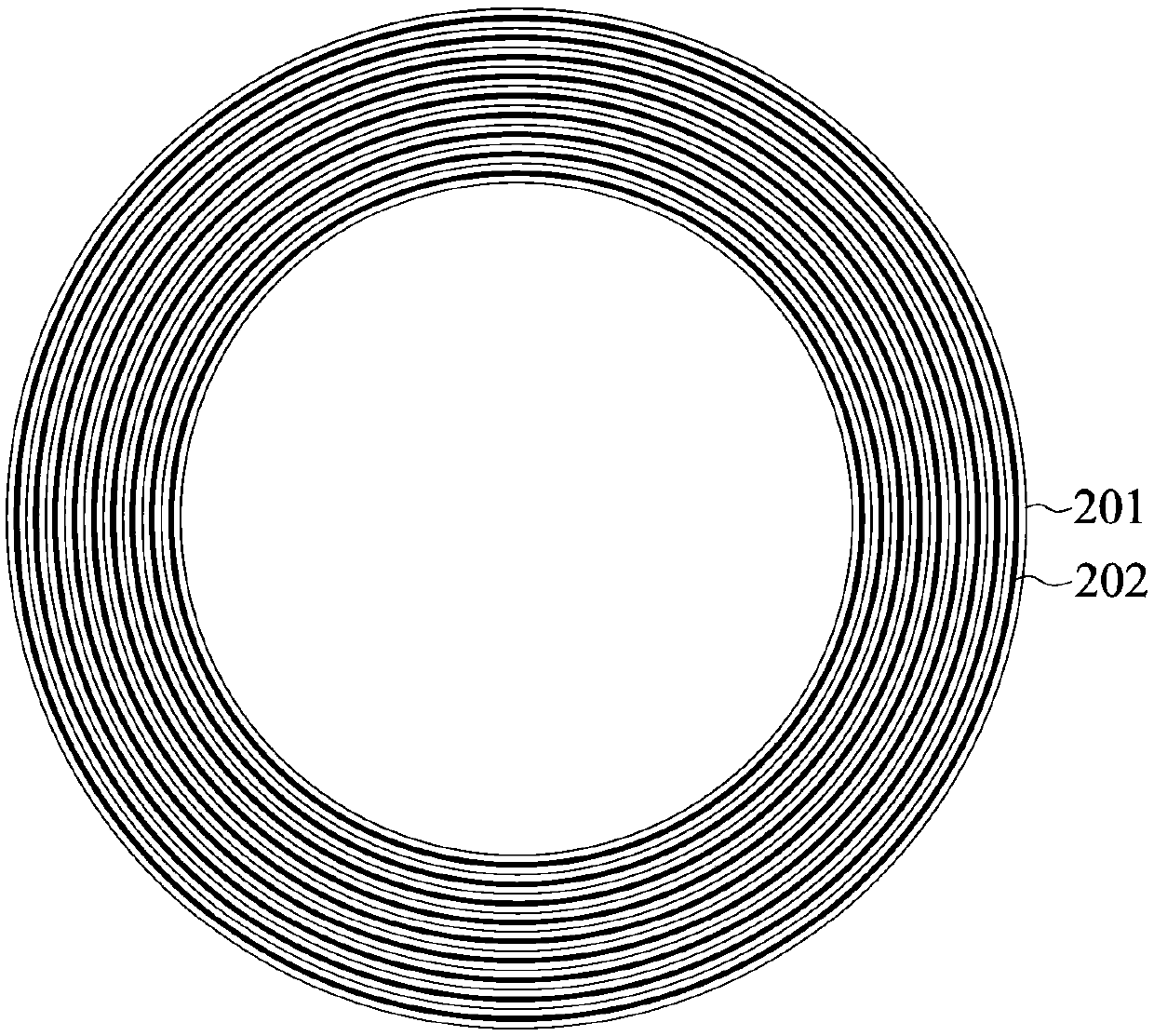

Embodiment 1

[0050] The preparation procedures and conditions of Embodiment 1 of the present invention (numbering: 4V) are as follows, and each material is described as follows, fiber: carbon fiber (Toray, T700SC, 12K); first / second resin: epoxy resin (Dow Chemical, Epon 828); multilayer carbon nanotubes: A-MWCNT1020, Xinyun Enterprise (accounting for 5wt% of composite resin layer); modified functional group: amine group (according to J.Mater.Chem.,2011,21,7337-7342 Methods). Preparation of a round tubular hollow body Taking the length 450mm X diameter 20mm and thickness 4.0mm as an example, first place 4 strip-shaped composite resin layers (thickness 70±2μm) on the fiber prepreg horizontally at an angle of 0° (θ°) On the cloth layer (thickness 80±2μm) (similar figure 1 shown, but the included angle is 0 degrees), the width L of the strip-shaped composite resin layer 1 The distance L from the plurality of strip-shaped composite resin layers 2 The ratio is 1:4. Then wrap the above-menti...

Embodiment 2

[0052] Embodiment 2 of the present invention (code number: 2V) preparation method and conditions are as described in Embodiment 1, change the width L of the composite resin layer of this strip 1 The distance L from the plurality of strip-shaped composite resin layers 2 The ratio is 1:2.

Embodiment 3

[0054] Embodiment 3 of the present invention (number: 3V) preparation method and condition are as described in embodiment 1, change the width L of the composite resin layer of this strip 1 The distance L from the plurality of strip-shaped composite resin layers 2 The ratio is 1:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com