Lifting balance monitoring control system for heavy-duty dump trucks and monitoring control method

A monitoring and control, dump truck technology, applied in the direction of loading and unloading vehicles, motor vehicles, vehicle parts, etc., can solve the problems of rough road, dump trucks prone to rollover accidents, and poor unloading environment for heavy dump trucks, to avoid side effects. The effect of a rollover accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The core of the present invention is to provide a lifting balance monitoring control system and monitoring control method for heavy-duty dump trucks. In order to enable those skilled in the art to better understand the solution of the present invention, the following describes the present invention in conjunction with the accompanying drawings and specific embodiments. For further details.

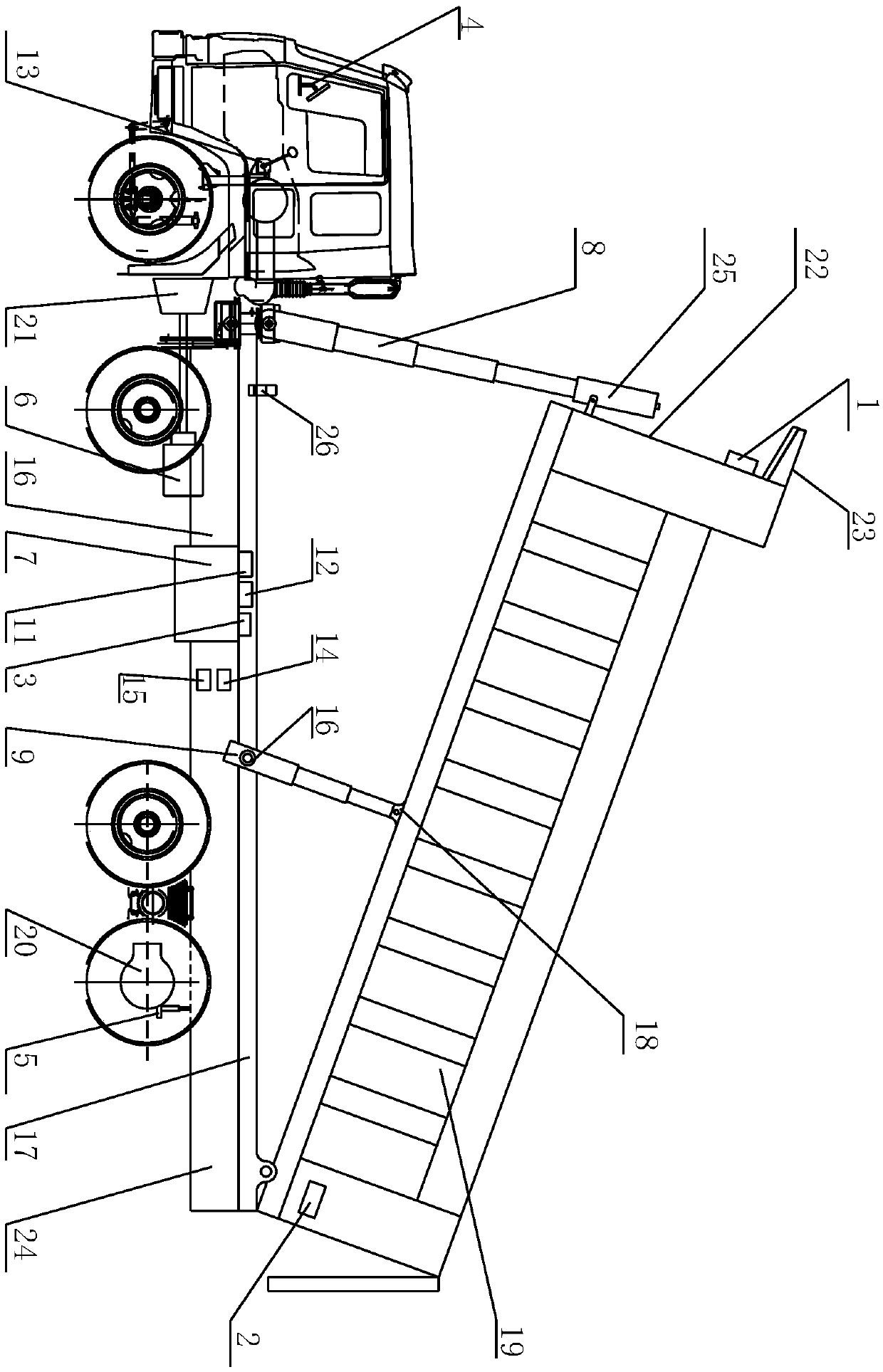

[0036] Please refer to figure 1 , figure 1 It is a structural schematic diagram of the present invention.

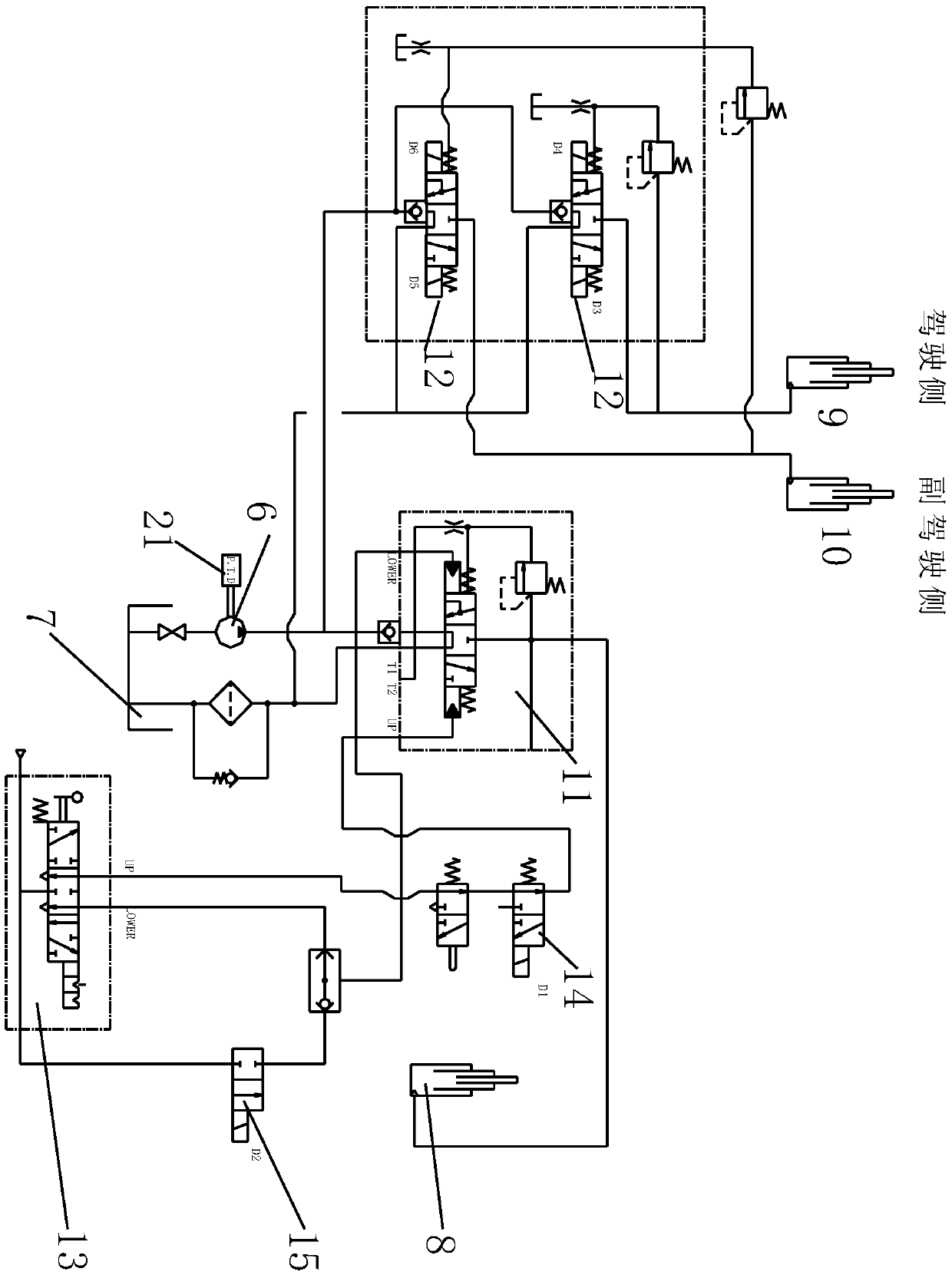

[0037] A lifting balance monitoring control system of a heavy dump truck, comprising a PLC control correction system and a hydraulic system.

[0038] 1. The PLC control correction system includes a roll angle sensor 1 , a lift angle sensor 2 , a PLC controller 3 , a liquid crystal display 4 and a displacement sensor 5 .

[0039] 2. The hydraulic system includes hydraulic oil pump 6, hydraulic oil tank 7, front straight top hydraulic cylinder 8, correcting hydraulic cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com