Polytetrafluoroethylene film

A technology of polytetrafluoroethylene and polytetrafluoroethylene powder, which is applied in the field of polytetrafluoroethylene film, can solve the problems of easy charging, easy pollution, and no wear resistance, and achieves improved electrical conductivity, good antistatic effect, and mechanical properties. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

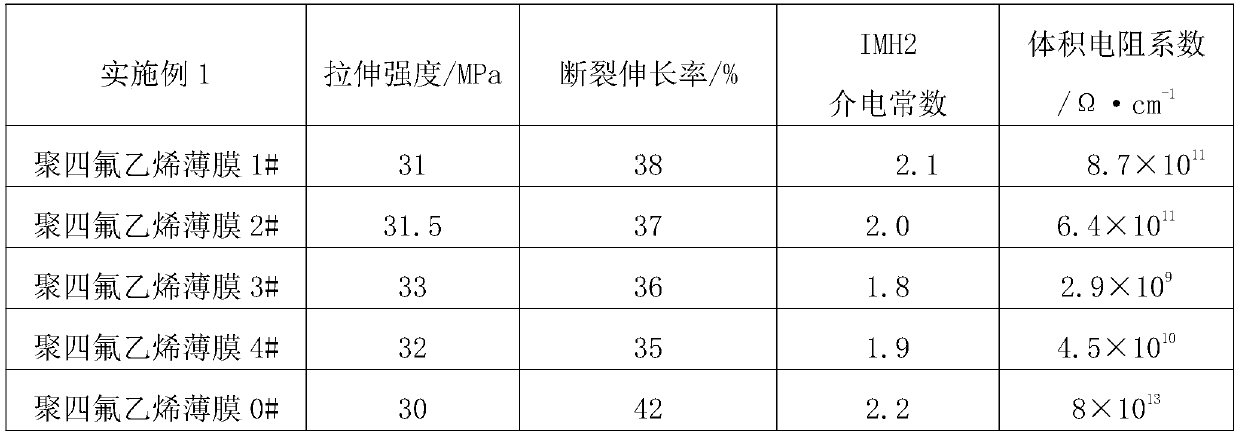

Embodiment 1

[0021] Embodiment 1 is loaded with the preparation of the mica sheet of tin dioxide

[0022] 1) calcining mica powder at 600°C for 4 hours to obtain calcined mica powder;

[0023] 2) Disperse 20g of calcined mica powder in 1L of ethanol, then use an ultrasonic crusher (250W) for ultrasonic exfoliation, collect the upper suspension, and then redisperse the remaining samples in an equal volume of ethanol to continue ultrasonic exfoliation. The upper layer is transparent, the collected upper layer suspensions are combined, centrifuged at 3000r / min, and dried to obtain nano-mica sheets;

[0024] 3) Disperse 1 g of nano-mica sheets obtained in step 2) in 100 mL of water to form a mica sheet suspension, adjust the pH to 1-2 with hydrochloric acid, add 0.4 g of SnCl 4 ·5H 2 O, stir at 80-100°C for 2-4h to form a light yellow powder, wash and dry, and calcinate at 600-800°C for 2-4h to obtain mica flakes loaded with tin dioxide;

Embodiment 2

[0026] The polytetrafluoroethylene film described in the present embodiment, by weight, is made up of following components:

[0027] 100 parts of polytetrafluoroethylene powder;

[0028] The prepared load of embodiment 1 has 2 parts of mica flakes of tin dioxide;

[0029] The preparation method of the polytetrafluoroethylene film described in this example is to mix the polytetrafluoroethylene powder in the above ratio and the mica sheet loaded with tin dioxide in a high-speed mixer, and then mold and sinter it to form a certain shape. After blanking, the oriented film is made by turning and rolling process, which is PTFE film 1#.

[0030] Example 2

[0031] The polytetrafluoroethylene film described in this embodiment consists of the following components in parts by weight:

[0032] 100 parts of polytetrafluoroethylene powder;

[0033] The prepared load of embodiment 1 has 3 parts of mica flakes of tin dioxide;

[0034] By the same preparation method as in Example 2, PTFE...

Embodiment 3

[0036] The polytetrafluoroethylene film described in this embodiment consists of the following components in parts by weight:

[0037] 100 parts of polytetrafluoroethylene powder;

[0038] The prepared load of embodiment 1 has 4 parts of mica flakes of tin dioxide;

[0039] By the same preparation method as in Example 2, PTFE film 3# was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com