Inner lining suspension type low temperature liquid storage and transportation vessel

A technology for cryogenic liquids and transport containers, applied in gas/liquid distribution and storage, pressure vessels, container filling methods, etc., can solve the problems of increasing safety hazards, short storage time of cryogenic liquids, etc., to reduce thermal bridges and reduce heat conduction leakage hot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

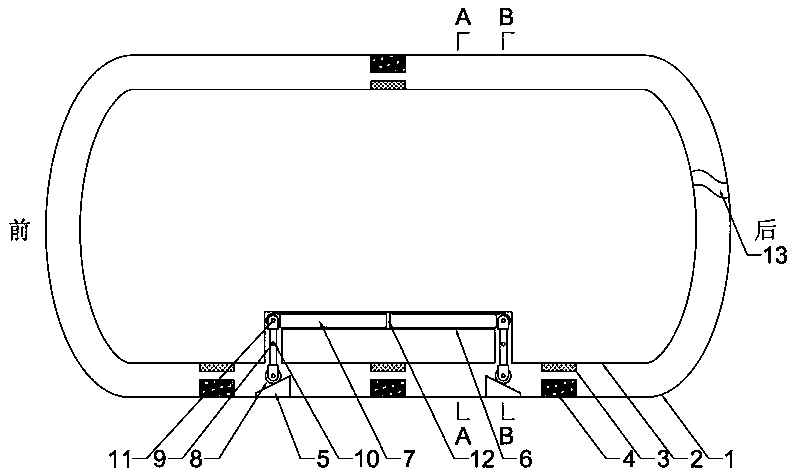

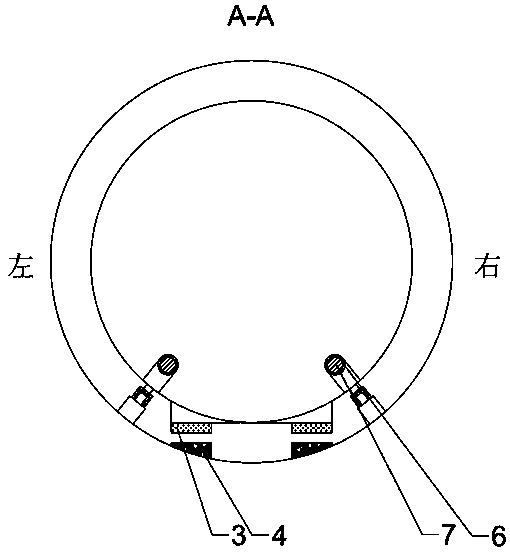

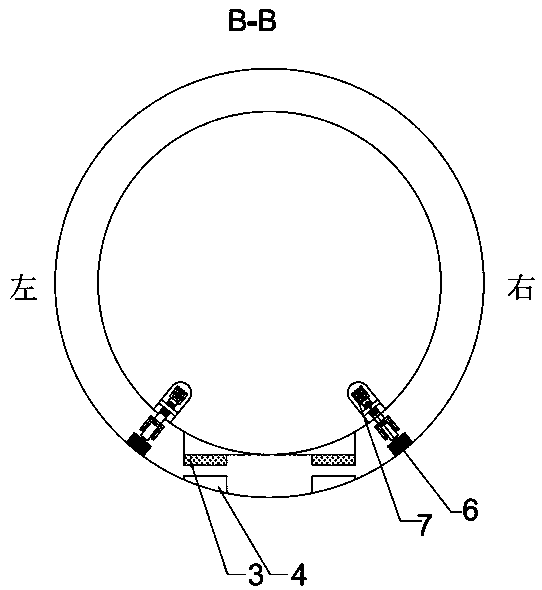

[0018] The following is a detailed elaboration and description of the inner tank suspension type cryogenic liquid storage and transportation container of the present invention in conjunction with the accompanying drawings and embodiments.

[0019] like figure 1 As shown, the container body of the inner tank suspension type cryogenic liquid storage and transportation container of the present invention is composed of an outer tank 1 and an inner tank 2 . A vacuum cavity is formed between the outer bladder 1 and the inner bladder 2 . The liner 2 is a non-magnetic material. On its outer wall, in addition to arranging traditional heat insulating materials, there are also a number of discrete superconductors 3 fixed on its lower and upper individual positions through structures with high thermal conductivity. The superconductors 3 and Liner 2 has good thermal contact. On the inner wall of the outer bladder 1 , a permanent magnet 4 is arranged at a position corresponding to the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com