Range hood

A range hood and oil guide technology, which is applied in the fields of oil fume removal, household heating, lighting and heating equipment, etc., can solve the problem of large noise of the range hood, poor stability of the overall structure of the range hood, and the inability to realize the filter screen Rotate speed adjustment and other issues to achieve the effect of prolonging the service life, convenient and quick disassembly and cleaning and installation and fixing, and improving purification, filtration and decomposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

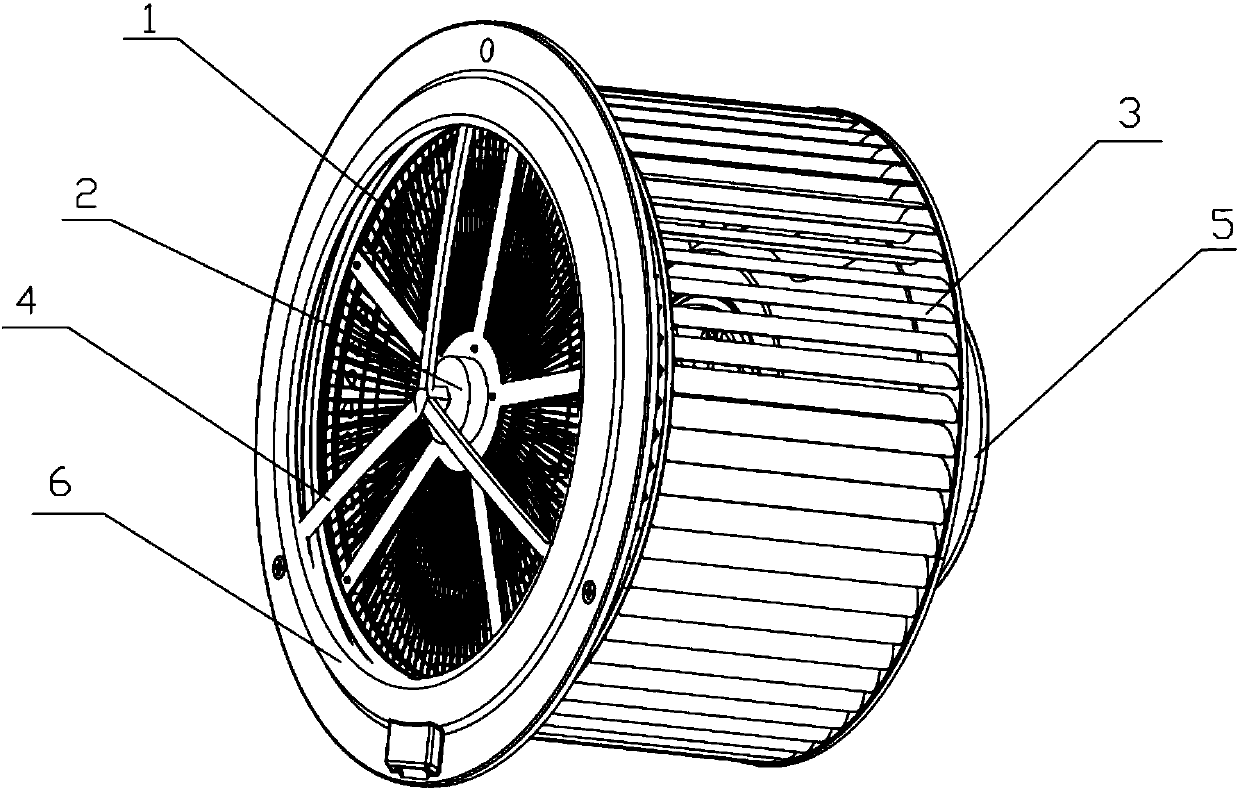

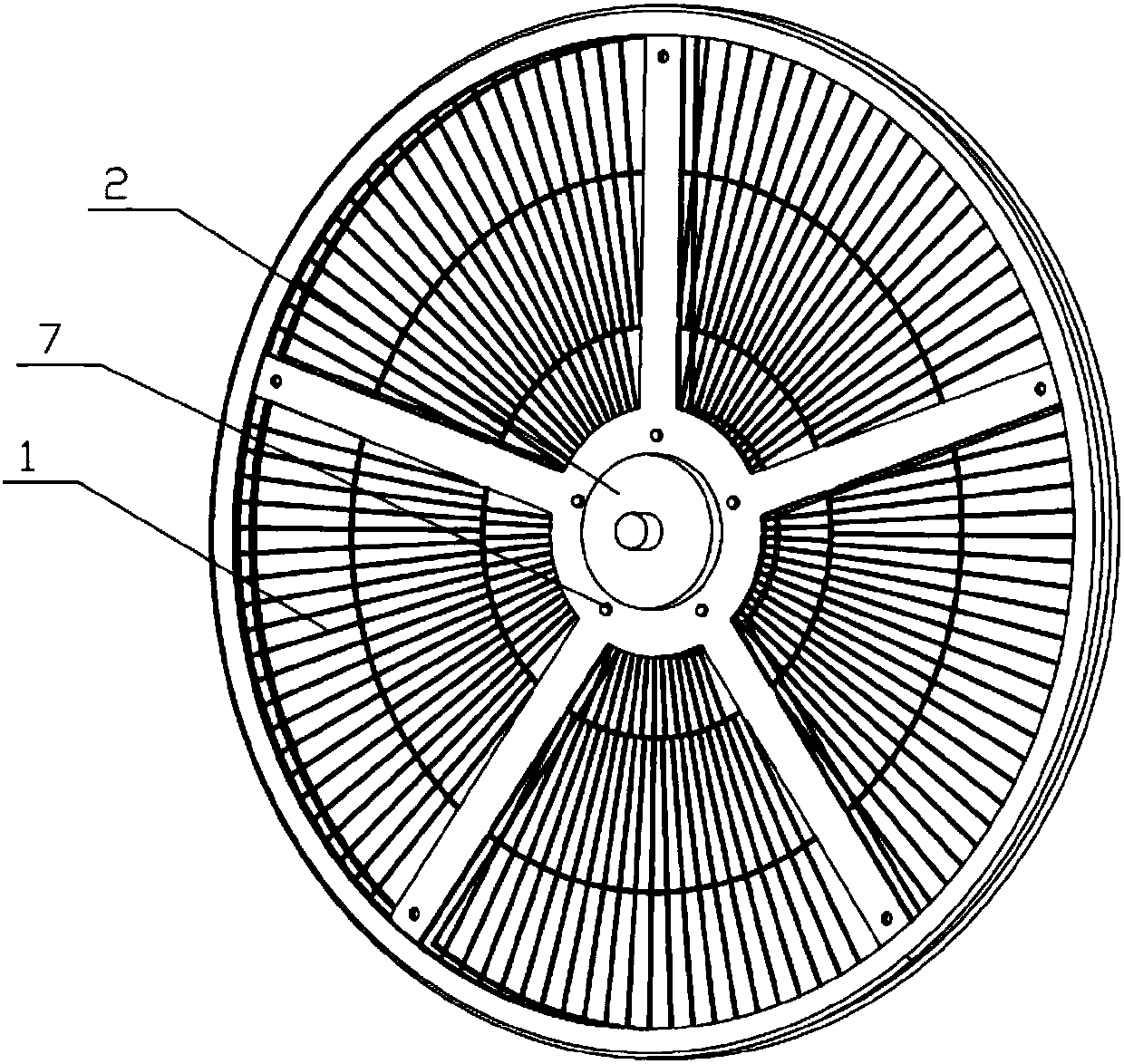

[0041] A range hood includes a motor 5, an impeller 3, a filter screen 1 installed on the front side of the impeller, an oil guide ring 6 arranged on the outer periphery of the filter screen 1, and a motor shaft 51 of the motor 5 drives the impeller 3 and the filter respectively Disk 1, the filter screen disk 1 and the motor 5 are meshed and connected via a speed change device 2, which adjusts the transmission ratio between the filter screen disk 1 and the motor shaft 51.

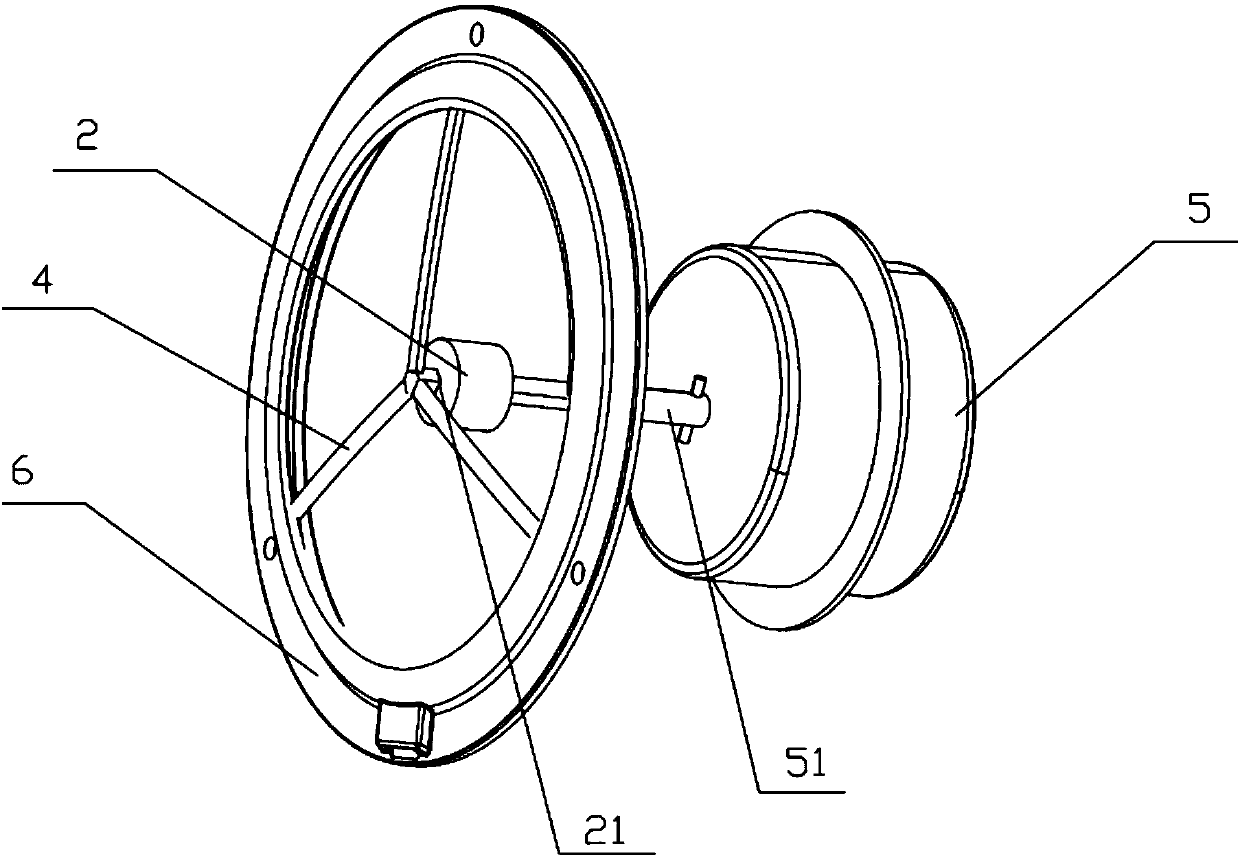

[0042] The speed change device 2 is arranged on the front side of the filter screen disc 1, the output end 21 of the speed change device 2 is connected to the oil guide ring 6, and the input end is connected to the motor shaft 51.

[0043] The filter screen 1 is fixed on the side of the speed change device 2 and is located between the speed change device 2 and the motor shaft 51.

[0044] The front side of the speed change device 2 is provided with a fixed bracket 4, the output end 21 of the speed change device 2 ...

Embodiment 2

[0060] A range hood includes a motor 5, an impeller 3, an oil guide ring 6 and a filter screen plate 1, and also includes a speed change device 2. The output end 21 of the speed change device 2 is connected to the oil guide ring 6, and the input end is connected to the motor shaft 51 , The filter screen 1 is arranged between the speed change device 2 and the motor shaft 51 and fixed on the side surface of the speed change device 2.

[0061] The transmission device 2 has a gear structure, and the motor shaft 51 is connected to the gear structure. The output end 21 of the transmission device 2 is connected to the inner side of the oil guide ring 6 via the fixed bracket 4. The transmission device 2 adjusts the filter screen 1 through the principle of harmonic gear transmission. Rotating speed.

[0062] figure 1 The partial structure of the range hood of the present invention is shown, that is, the motor 5, the impeller 3, the oil guide ring 6, the filter screen 1, the speed change dev...

Embodiment 3

[0079] A range hood includes a motor 5, an impeller 3, an oil guide ring 6 and a filter screen plate 1, and also includes a speed change device 2. The output end 21 of the speed change device 2 is connected to the oil guide ring 6, and the input end is connected to the motor shaft 51 , The filter screen 1 is arranged between the speed change device 2 and the motor shaft 51 and fixed on the side surface of the speed change device 2.

[0080] The transmission device 2 has a gear structure, and the motor shaft 51 is connected to the gear structure. The output end 21 of the transmission device 2 is connected to the inner side of the oil guide ring 6 via the fixed bracket 4. The transmission device 2 adjusts the filter screen 1 through the principle of harmonic gear transmission. Rotating speed.

[0081] The fixed bracket 4 has a symmetrical structure with a sleeve in the center, and a plurality of legs radiate outward from the sleeve. The ends of the legs extend to the inner side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com