Method for pretreating to-be-recycled ternary positive plate

A cathode sheet and pretreatment technology, applied in the field of lithium ion batteries, can solve the problems of large pollution, high energy consumption and cost, poor separation effect, etc., achieve high separation rate, small equipment investment, and improve slag-liquid filtration and separation performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

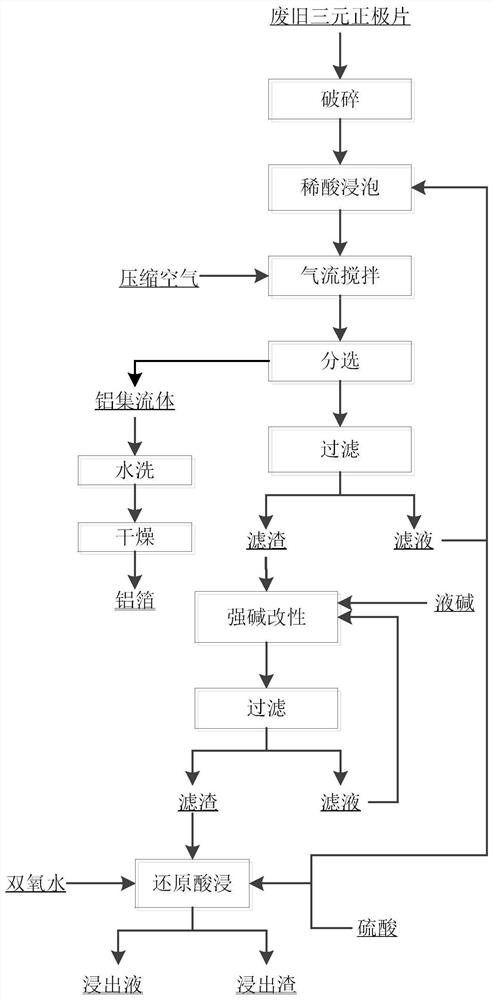

[0069] According to the method described below, the ternary positive electrode sheet to be recovered is pretreated, and the method comprises the following steps:

[0070] (1) First, the ternary positive electrode sheet to be recovered is broken into a block with a width of 5 cm;

[0071] Weigh 92.65g block-shaped positive electrode sheet, add it to 1L sulfuric acid solution with a concentration of 0.7mol / L, and soak at 25°C for 30min;

[0072] In the above system, the compressed air is introduced into the air flow stirring treatment, the position of the air flow is 3 / 4 of the liquid level of the system, the time is 5min, and the flow rate of the compressed air is 1L / min;

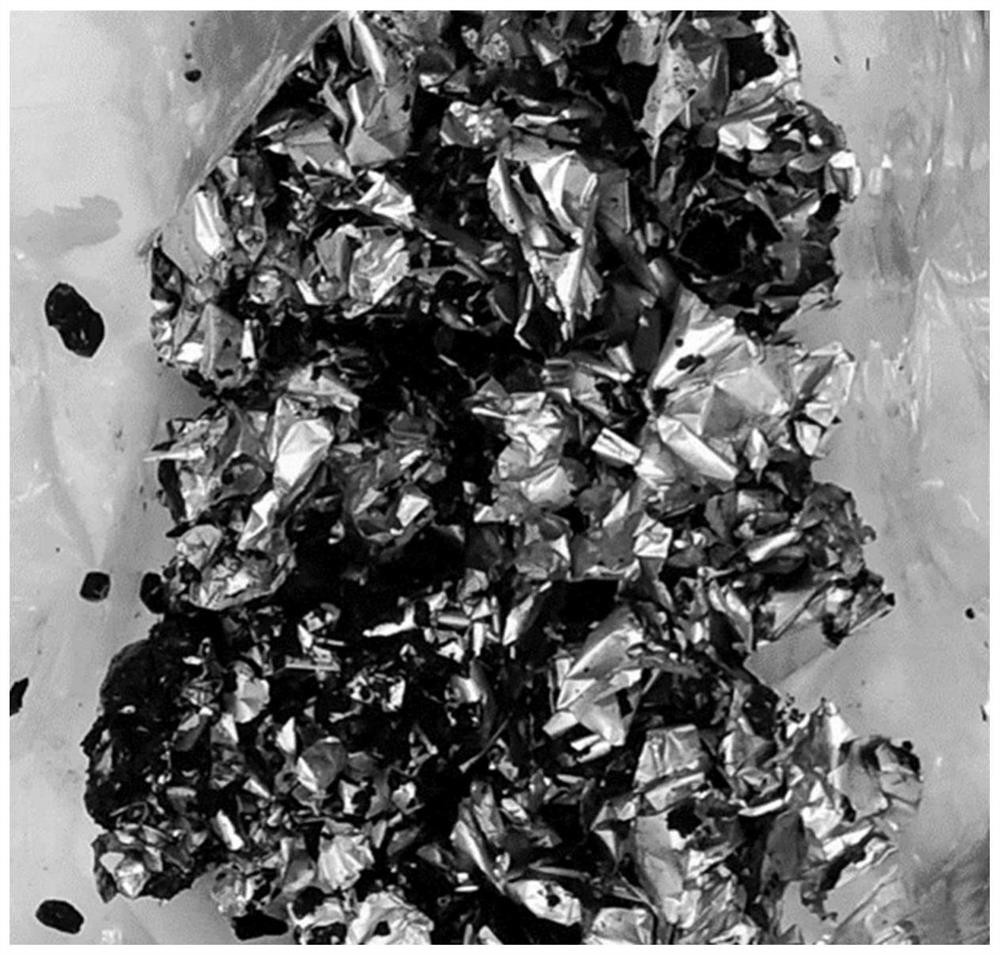

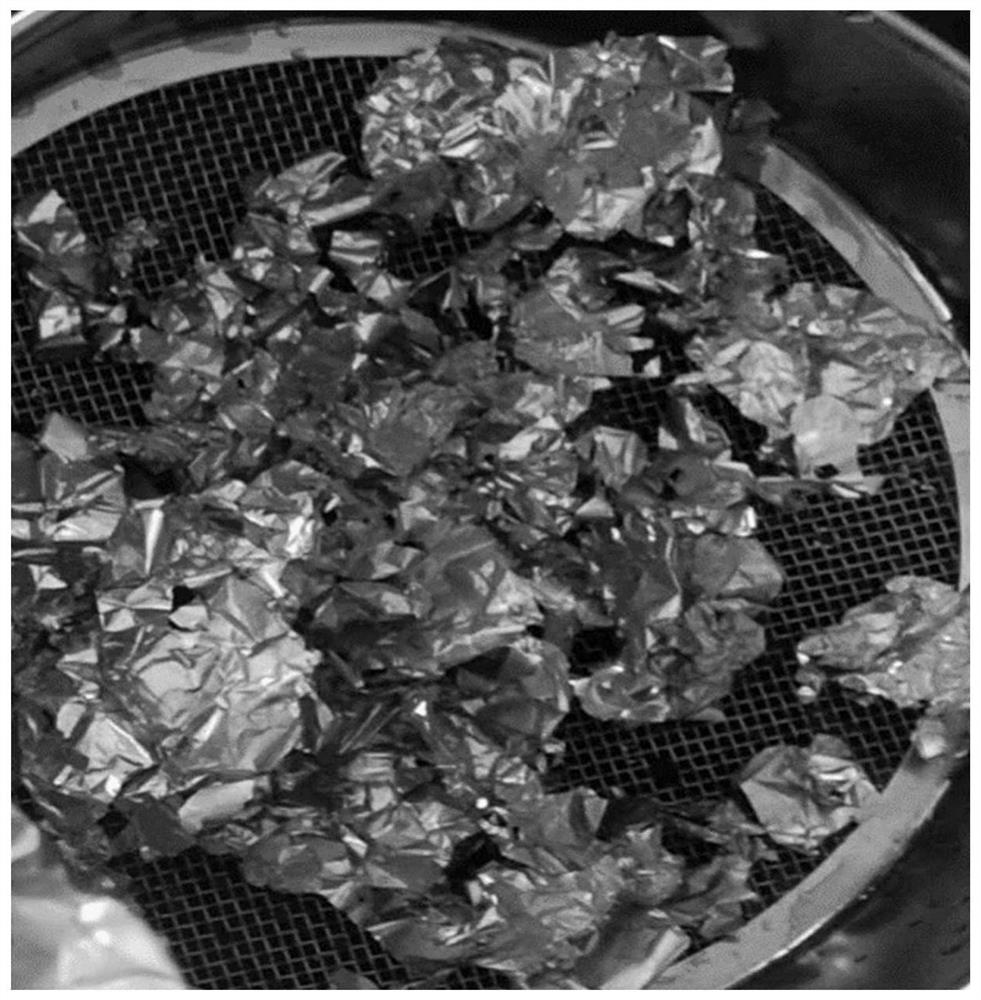

[0073] (2) Pass the product in step (1) through a primary sieve and a secondary sieve successively, the aperture of the primary sieve is 1cm, and the aperture of the secondary sieve is 2mm; The object is a large piece of aluminum foil;

[0074] Drying the first-stage sieve and then passing through the seco...

Embodiment 2

[0081] According to the method described below, the ternary positive electrode sheet to be recovered is pretreated, and the method comprises the following steps:

[0082] (1) First, the ternary positive electrode sheet to be recovered is broken into a block with a width of 5 cm;

[0083] Weigh 120.16g block-shaped positive electrode sheet, add it to 2L sulfuric acid solution with a concentration of 0.5mol / L, and soak it at 25°C for 40min;

[0084] In the above system, the compressed air is introduced into the air flow stirring process, the position of the air flow is 2 / 3 of the liquid level of the system, the time is 8min, and the flow rate of the compressed air is 2L / min;

[0085] (2) the product in step (1) is passed through a primary sieve and a secondary sieve successively, the aperture of the primary sieve is 0.5cm, and the aperture of the secondary sieve is 0.5mm; The sieve is a large piece of aluminum foil;

[0086] Drying the first-stage sieve and then passing throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com