PHBV (Polyhydroxylbutyrate Valerate) composite membrane with high water flux, as well as preparation method and application thereof

A composite membrane and flux technology, used in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of inability to achieve filtration, poor mechanical properties, poor pressure resistance, etc. Filtration separation ability, the effect of improving feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

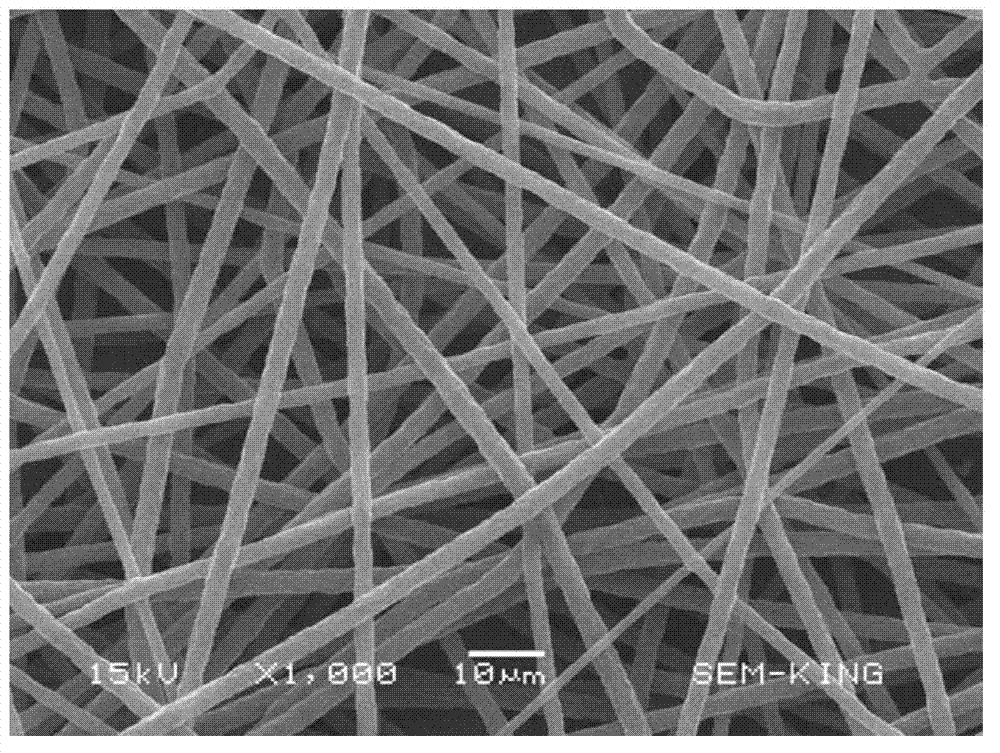

Embodiment 1

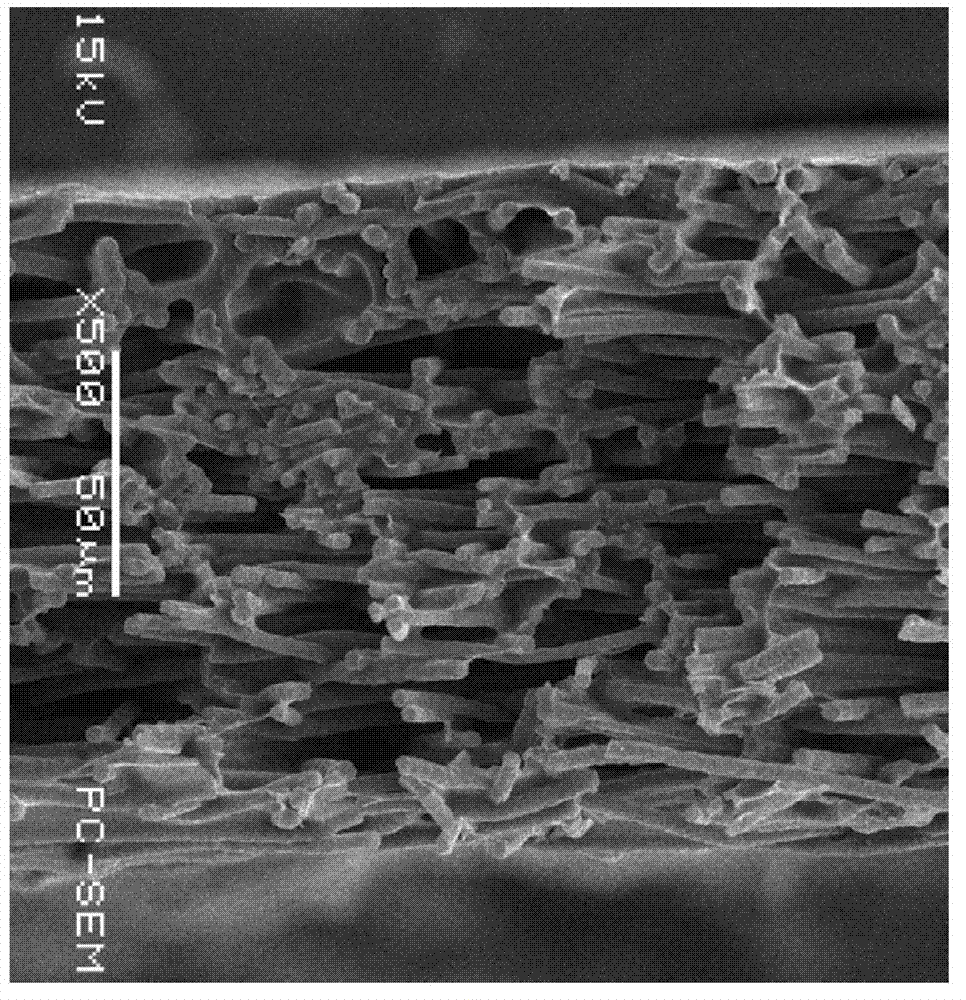

[0026] Weigh 2g PHBV and dissolve it in 40ml chloroform / absolute ethanol mixed solution, adjust the volume ratio of chloroform / absolute ethanol to 3 / 1, heat it in a water bath thermostat at 60℃ for 2.5h, and configure the concentration to 5wt% Electrospinning was performed with the PHBV solution, the spinning solution advancing speed was 4mL / h, the voltage was 8kV, the receiving distance was 10cm, and PHBV fibers with an average diameter of 0.5μm were obtained, and the average fiber membrane thickness was 100μm. Weigh 0.36g of PVA and dissolve it in 1.64mL of distilled water, heat to dissolve in a water bath at 95°C, add 0.5wt% of glycerol and 0.5wt% of PEG, stir and dissolve with a magnetic stirrer, after fully dissolving, stand for defoaming to obtain A PVA solution with a concentration of 18 wt%. The PVA solution is coated on the prepared PHBV electrospun fiber membrane to obtain a PHBV / PVA composite membrane with a smooth and uniform surface. Among them, the volume ratio o...

Embodiment 2

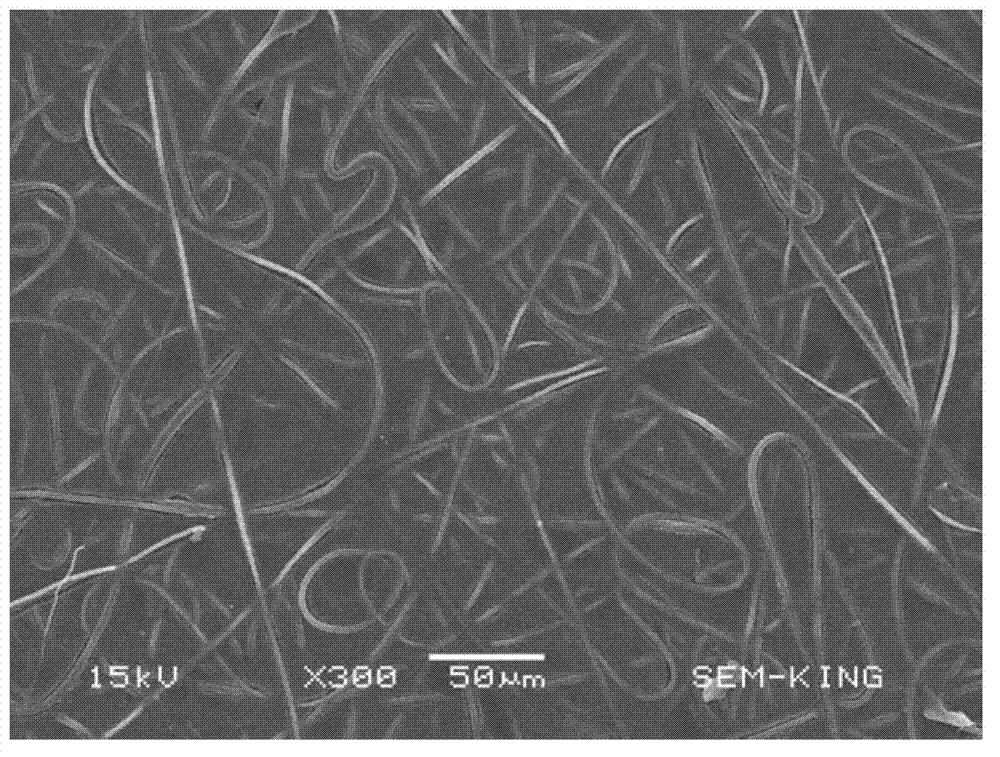

[0029] Weigh 2.4g PHBV and dissolve it in 17.6mL chloroform / anhydrous methanol mixed solution, adjust the volume ratio of chloroform / anhydrous methanol to 90 / 10, heat it in a water bath thermostat at 60℃ for 2.5h, and configure the concentration to 12wt % PHBV solution, electrospinning, spinning solution advancing speed 1mL / h, voltage 16kV, receiving distance 25cm, to obtain PHBV fiber with a diameter of 10μm and a fiber film thickness of 150μm. Weigh 1.2g of CS and dissolve it in 28.8mL, glacial acetic acid, add 4wt% of glycerol and 3wt% of PVP, place the coating solution in a water bath at 60°C and heat to dissolve it. Under the action of a magnetic stirrer, it will be fully dissolved and statically After defoaming, a CS solution with a concentration of 4 wt% is obtained. The CS solution is coated on the prepared PHBV electrospun fiber membrane to obtain a PHBV / CS composite membrane with a smooth and uniform surface. Among them, the volume ratio of CS coating liquid to PHBV f...

Embodiment 3

[0031] Weigh 0.4g PHBV and dissolve it in 4.6mL chloroform / absolute ethanol mixed solution, adjust the volume ratio of chloroform / absolute ethanol to 5 / 1, heat it in a water bath thermostat at 60℃ for 2.5h, and configure the concentration as Electrospinning was performed with 8wt% PHBV solution, spinning solution advancing speed 1.5mL / h, voltage 12kV, receiving distance 15cm, and obtaining PHBV fiber with diameter of 6μm and fiber film thickness of 10μm. Weigh 0.1g of PVA and dissolve in 3.8mL of water; weigh 0.12g of CS and dissolve in 7mL of formic acid, add 2.5wt% glycerol and 2.5wt% PVP, heat to dissolve in a water bath at 95℃, and stir to dissolve with magnetic stirring. The bubble is left standing to obtain a PVA / CS mixed solution with a concentration of 4wt%. The PVA / CS mixture solution is coated on the prepared PHBV electrospun fiber membrane by a casting method, wherein the volume ratio of the PVA / CS coating solution to the PHBV fiber layer is 7:3. Put the coated PHBV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com