A kind of duplex stainless steel material and its preparation method and its application in submersible oil pump vanes and guide wheels

A technology of duplex stainless steel and submersible electric pumps, which is applied to components, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as difficulties and shortage of nickel resources, and achieve high pass rate and abundant resources , good corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

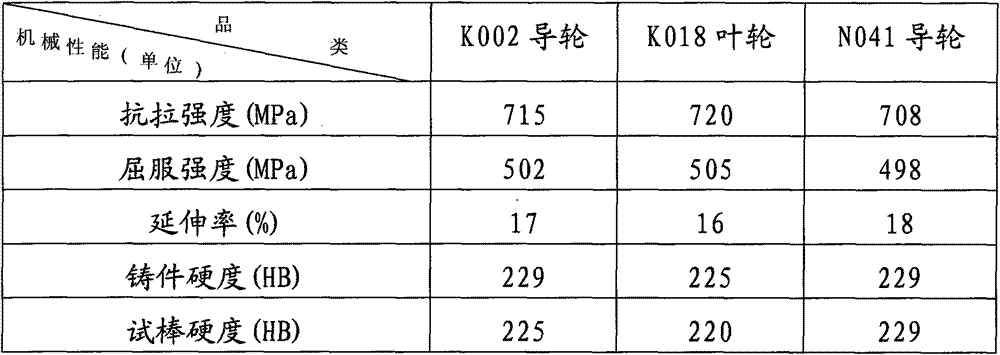

[0014] Application of a duplex stainless steel material in the K002 guide wheel of an electric submersible pump.

[0015] When making the K002 guide wheel shell, the shell is made of water glass, injected at 900°C for 4 hours and roasted, and then the high-temperature molten steel smelted with duplex stainless steel is injected into the shell, and the shell temperature is not lower than 450°C. The ladle temperature was not lower than 700°C, and the pouring temperature was not lower than 1600°C. As a result, a total of 50 pieces were poured, of which 45 pieces were rough finished products, and 5 pieces had molten steel residue in the runner. After professional polishing, one piece was scrapped. 4 The parts are qualified, and the qualified rate is higher than that of similar products usually cast with high nickel cast iron.

[0016] K002 guide wheel (K series is the exclusive product of our company for the American GM company) is a casting with a very special structure in the gu...

Embodiment 2

[0018] Application of a duplex stainless steel material in K018 impeller of electric submersible pump.

[0019] When making the K018 impeller shell mold, fine quartz sand is selected for the shell mold, and it is roasted at a high temperature of 900°C for 4 hours, and then high-temperature molten steel smelted with duplex stainless steel is injected into the shell mold, and the shell mold temperature is not lower than 600°C. The pouring temperature was not lower than 1620°C. As a result, a total of 50 pieces were poured, of which 45 pieces were rough finished products, which were cleaned and polished in the subsequent process, and 45 pieces were qualified products, which basically achieved the purpose of this trial production. The rough pass rate is higher than usual. Similar products poured in cast iron are higher.

[0020] For the K018 impeller, the average thickness of the blades is 2mm and the height is 14mm. If the upper and lower cover plates are too thick, shrinkage hol...

Embodiment 3

[0022] Application of a duplex stainless steel material in N041 guide wheel of electric submersible pump.

[0023] When making the N041 guide wheel shell mold, the shell mold is made of fine quartz sand, injected at 900°C for 4 hours and roasted, and then the high-temperature molten steel melted with duplex stainless steel is injected into the shell mold, and the shell mold temperature is not lower than 450°C , the temperature of the ladle is not lower than 700°C, and the pouring temperature is not lower than 1600°C. In this example, a total of 50 products were poured. After subsequent cleaning, 48 finished products were found, and 2 were judged as waste products due to insufficient pouring of the inner shaft hub. Generally, similar products cast by high nickel cast iron are higher.

[0024] N041 guide wheel (N series is our company's exclusive product for Baker Hughes in the United States) is another example of difficult casting in the guide wheel casting. On the surface, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com