Composite filter membrane, preparation method thereof, and industrial wastewater treatment method

A composite filtration and composite nanofiber technology, which is applied in the field of composite filtration membranes and their preparation, can solve the problems that the filtration performance and adsorption and separation performance of nanofiber filtration membranes have not been greatly improved, and the production scale is small, and the improvement is achieved. Filter separation performance, improve filter performance, increase the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

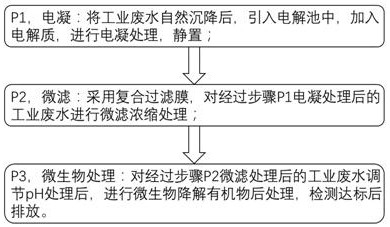

[0040] The invention provides a kind of preparation method of composite filter membrane, comprises the steps:

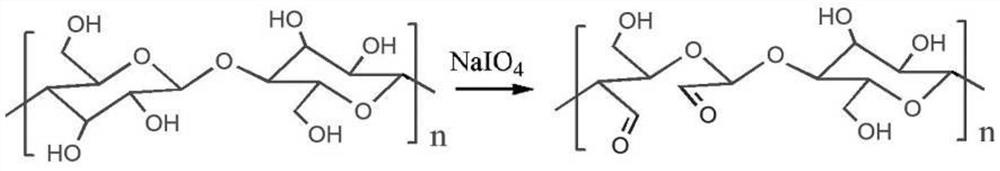

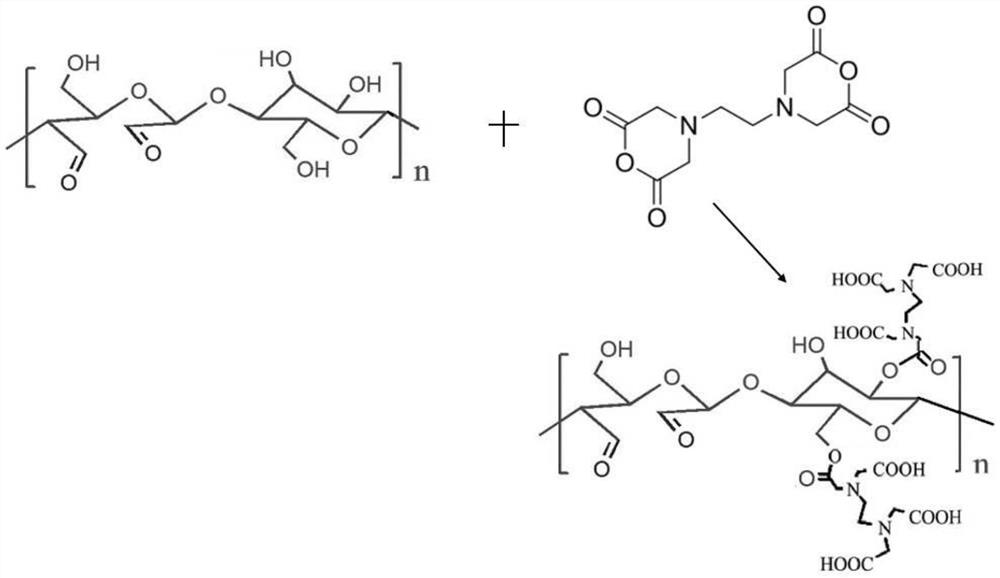

[0041] S1. Uniformly disperse cellulose nanocrystals in sodium periodate solution, react at 45-55°C for 1.5-2.5 hours, add ethanol, and perform dialysis to obtain oxidatively modified cellulose nanocrystals; Disperse the element nanocrystals in DMF to obtain the first dispersion liquid, disperse ethylenediaminetetraacetic acid dianhydride in DMF to obtain the second dispersion liquid, and slowly drop the second dispersion liquid at 70-80°C under the protection of nitrogen into the first dispersion liquid, stirred and reacted for 42 to 54 hours, centrifuged, washed, and freeze-dried to obtain cellulose nanocrystals modified by formylation and carboxylation;

[0042] S2. Mix the modified cellulose nanocrystals prepared in step S1 and the thermoplastic polymer in a predetermined ratio and uniformly melt and granulate to obtain a blended masterbatch; perform a two-compon...

Embodiment 1

[0055] Embodiment 1 of the present invention provides a kind of preparation method of composite filter membrane:

[0056] S1. Uniformly disperse 1g of cellulose nanocrystals (CNC) in 100ml of sodium periodate solution (sodium periodate content is 1g), ultrasonically disperse for 10min, react at 40°C for 2h, and add 20ml of ethanol to terminate the reaction. Then put the suspension into a dialysis bag with a molecular weight cut-off of 1000, and dialyze it with a large amount of deionized water for 2 days until the pH value of the suspension is neutral, and obtain aldehyde-modified cellulose nanocrystals;

[0057] Disperse the aldehyde-modified cellulose nanocrystals in 50mlDMF and ultrasonically disperse for 10min to obtain the first dispersion, disperse ethylenediaminetetraacetic dianhydride in 50mlDMF and ultrasonically disperse for 5min to obtain the second dispersion, wherein , the molar ratio of ethylenediaminetetraacetic dianhydride to the hydroxyl groups on the surface ...

Embodiment 2-3

[0079] The difference with Example 1 is: in step S1, cellulose nanocrystal (CNC) and sodium periodate (NaIO 4 ) The mass ratio setting is different, and other steps are all the same as in Example 1, and are not repeated here.

[0080] Table 1 is the parameter setting in embodiment 1-3 and comparative example 1

[0081] Example CNC and NaIO 4 mass ratio

Example 1 1:1 Example 2 1:0.5 Example 3 1:1.5

[0082] With the increase of the mass ratio of cellulose nanocrystals (CNC) to sodium periodate (NaIO4), the content of aldehyde groups in cellulose nanocrystals gradually increases, but the yield of aldylated cellulose nanocrystals will appear This is mainly due to the fact that sodium periodate oxidizes the hydroxyl groups on the cellulose nanocrystals to aldehyde groups, and at the same time, the strong oxidative properties will also cause the oxidative degradation of a part of the cellulose nanocrystals. High, the phenomenon that the yield...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com