A vacuum drying device for powder metallurgy

A vacuum drying device and powder metallurgy technology, which is used in drying cargo handling, drying solid materials, drying solid materials without heating, etc. Uniform distribution and drying efficiency, increase the convective heat transfer coefficient, and avoid the effect of condensed liquid droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

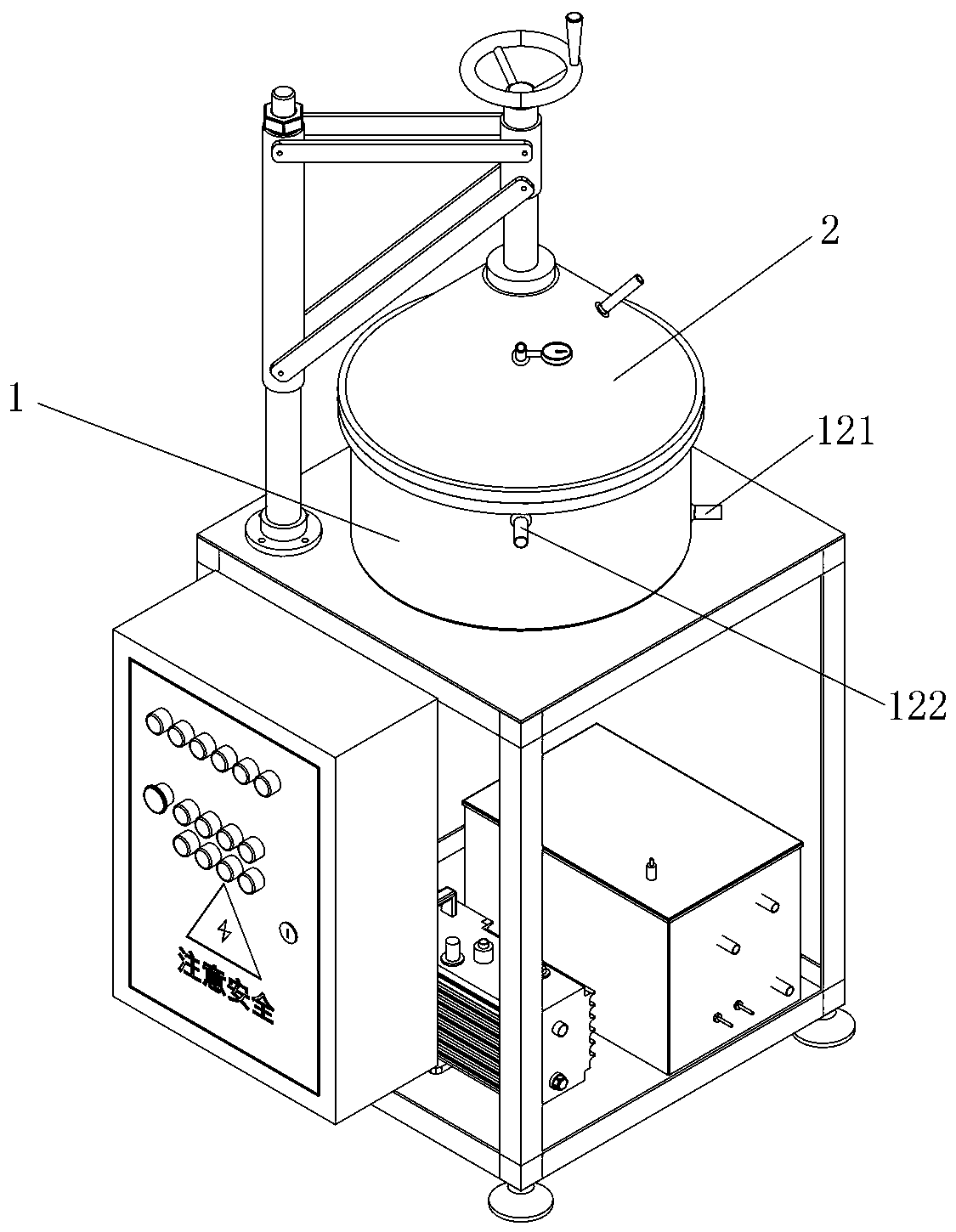

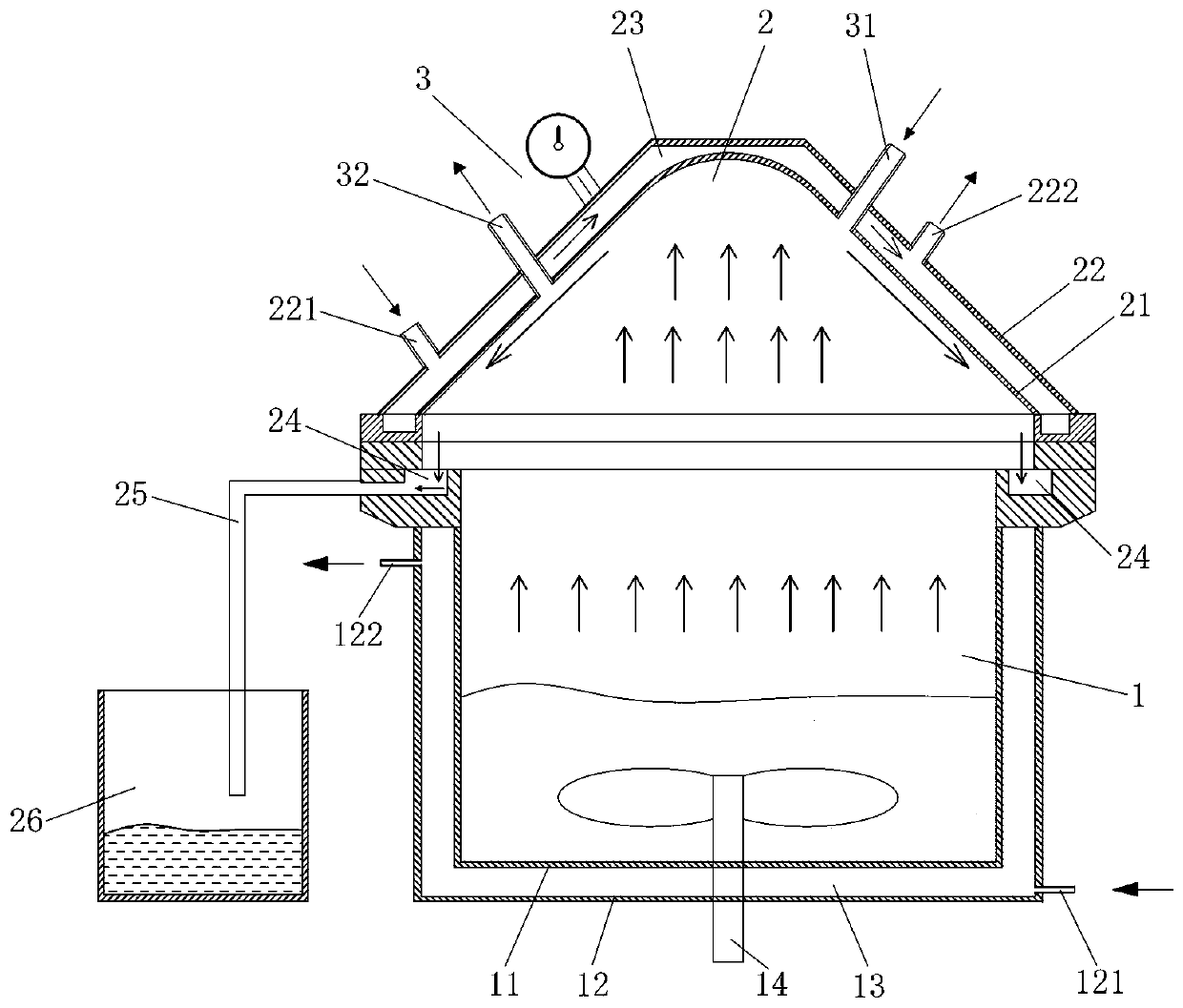

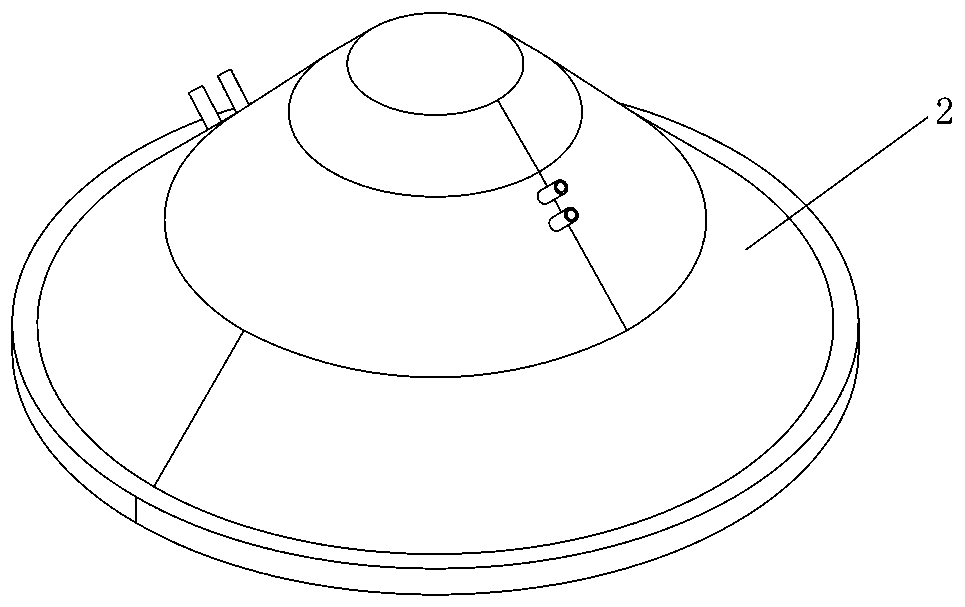

[0038] Such as Figure 1 to Figure 6 As shown, the vacuum drying device for powder metallurgy in this embodiment includes a cylinder body 1 and a top cover 2 for condensing and guiding the steam out. The cylinder body 1 and the top cover 2 are hermetically connected to form a closed cavity . Specifically, the connection between the cylinder body 1 and the top cover 2 is connected by a sealing flange to ensure good airtightness of the device as a whole. By inducing the rapid condensation and discharge of steam at the top cover, the drying efficiency and quality are greatly improved.

[0039] In this embodiment, the top cover 2 includes a top cover inner wall 21, a top cover outer wall 22, and a cooling medium circulation channel 23 interlayered between the top cover inner wall 21 and the top cover outer wall 22, and a cooling medium inlet 221 is opened on the top cover outer wall 22. And the cooling medium outlet 222 , the cooling medium inlet 221 and the cooling medium outle...

Embodiment 2

[0056] The vacuum drying device of this embodiment is basically the same as that of Embodiment 1, the main difference is that: in this embodiment, the inner wall 21 of the top cover is in the shape of a spherical surface with the middle protruding upward.

[0057] In this embodiment, the diameter of the bottom of the top cover 2 is 800 mm, and the angle α between the wall surface of the top cover inner wall 21 and the horizontal plane is 46°.

[0058] In this embodiment, the included angle β between the line connecting the cross-section points adjacent to and located on both sides of the top cover 2 and the horizontal plane is 2.5°.

[0059] In this embodiment, the depth h of the arc-shaped inner concave surface on the upper surface of the diversion groove 211 is 2.5mm, the width w of the arc-shaped inner concave surface is 6mm, and the cooling medium between the top cover inner wall 21 and the top cover outer wall 22 The circulation channel 23 has a thickness of 23mm.

[006...

Embodiment 3

[0063] The vacuum drying device of this embodiment is basically the same as that of Embodiment 1, the main difference being that: in this embodiment, the inside of the diversion groove 211 is a hollow structure, and the inner cavity of the diversion groove 211 is connected with the cooling mechanism on the top cover 2. The medium circulation channel 23 is connected.

[0064] In this embodiment, the axis of the cooling medium inlet 221 coincides with the tangent of the inner cavity of the guide groove 211 at the bottom.

[0065] In this embodiment, the diameter of the bottom of the top cover 2 is 650 mm, and the angle α between the inner wall 21 of the top cover and the horizontal plane is 45.5°.

[0066] In this embodiment, the included angle β between the connecting line between the adjacent cross-section points located on both sides of the top cover 2 and the horizontal plane is 2.3°.

[0067] In this embodiment, the depth h of the circular arc-shaped inner concave surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com