Bundled fiber fracture sound measuring device and method adopting symmetric displacement of tandem pickups

A technology of fiber breakage and sound pick-up, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to measure, inability to determine the degree of damage, inability to apply bundle fiber collection and detection, etc., to overcome inconsistencies in propagation and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: hemp fiber bundle

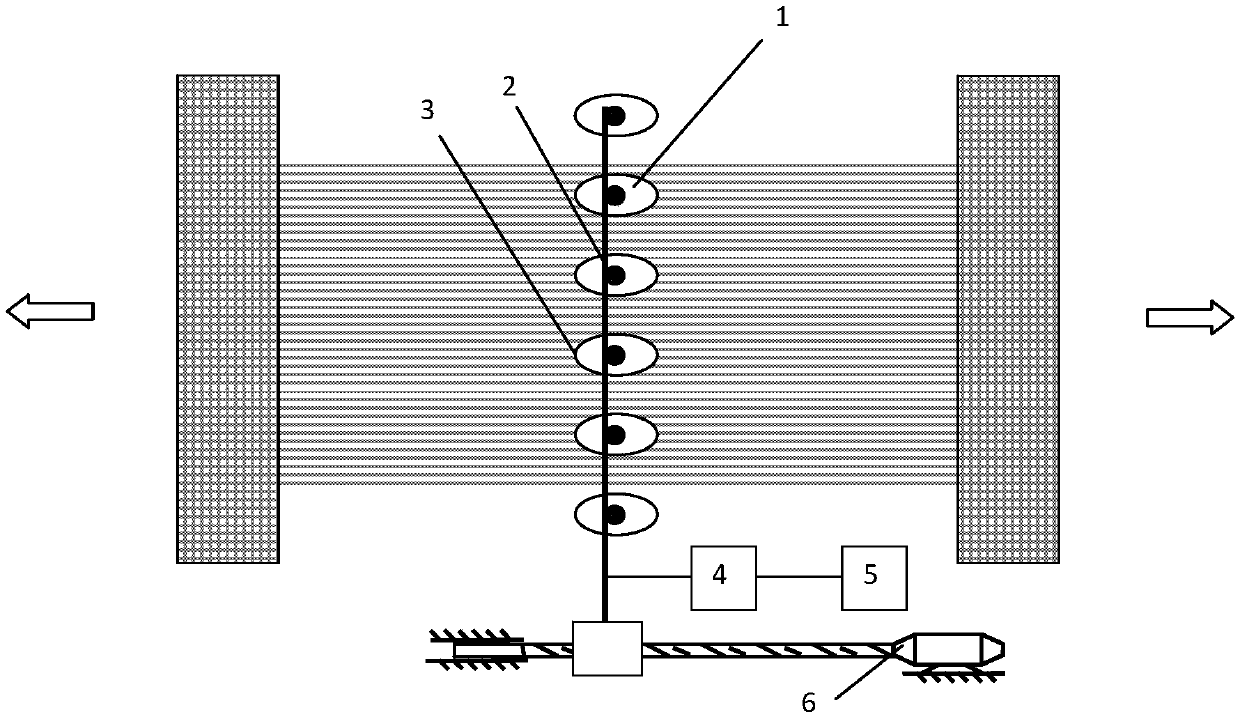

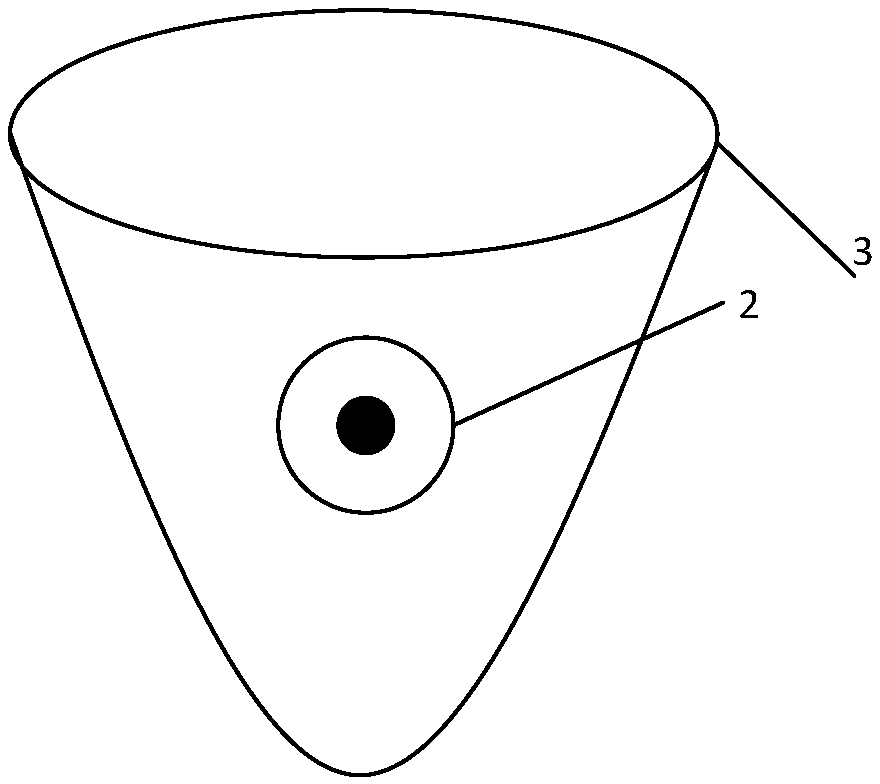

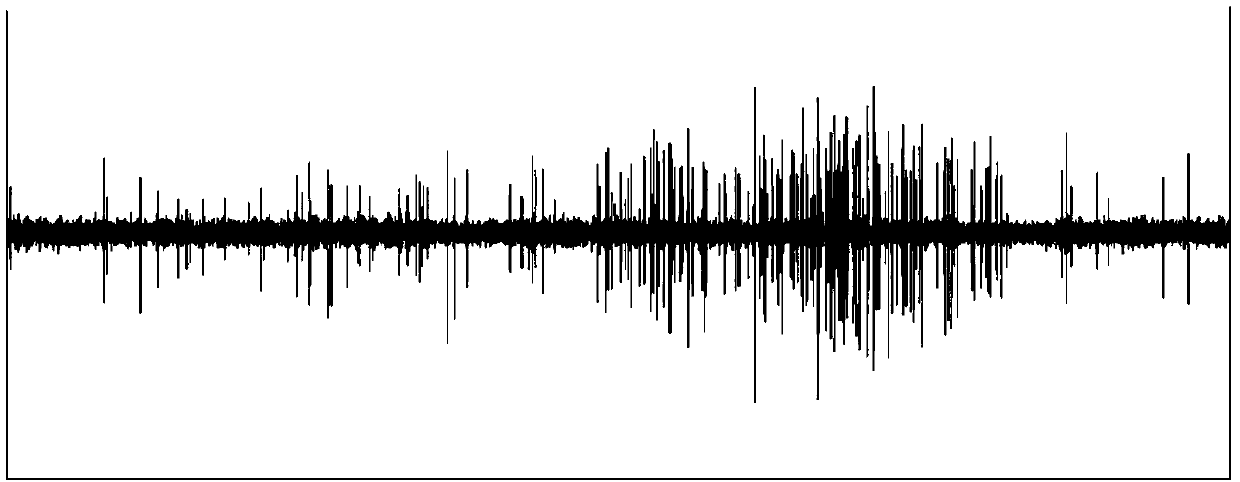

[0027] The bundle fiber is clamped at both ends of the holder, and several pickups 1 are arranged in a longitudinal array to form a pickup array, and the pickup array is arranged in the bundle fiber and completely covered by the bundle fiber. The sound pickup 1 is connected with the acquisition module 4 and the analysis system 5 on the computer. When the fiber bundle is stretched, the fiber is damaged, and the acquisition module 4 collects the fiber fracture acoustic signal through the pickup array, and the analysis system 5 forms a signal waveform through the received fiber fracture acoustic signal, and displays the signal waveform on the computer. When the fiber breaks, the signal waveform has obvious peaks and troughs. By analyzing and calculating the characteristics of the signal waveform of the fiber fracture acoustic signal collected by each pickup, the internal force, damage, and fracture of the bundle fiber during the stretchin...

Embodiment 2

[0028] Example 2: Carbon Fiber Bundle

[0029] The bundle fiber is clamped at both ends of the holder, and several pickups 1 are arranged in a longitudinal array to form a pickup array, and the pickup array is arranged in the bundle fiber and completely covered by the bundle fiber. The sound pickup 1 is connected with the acquisition module 4 and the analysis system 5 on the computer. When the fiber bundle is stretched, the fiber is damaged, and the acquisition module 4 collects the fiber fracture acoustic signal through the pickup array, and the analysis system 5 forms a signal waveform through the received fiber fracture acoustic signal, and displays the signal waveform on the computer. When the fiber breaks, the signal waveform has obvious peaks and troughs. By analyzing and calculating the characteristics of the signal waveform of the fiber fracture acoustic signal collected by each pickup, the internal force, damage, and fracture of the bundle fiber during the stretching...

Embodiment 3

[0030] Example 3: wool fibers

[0031] The bundle fiber is clamped at both ends of the holder, and several pickups 1 are arranged in a longitudinal array to form a pickup array, and the pickup array is arranged in the bundle fiber and completely covered by the bundle fiber. The sound pickup 1 is connected with the acquisition module 4 and the analysis system 5 on the computer. When the fiber bundle is stretched, the fiber is damaged, and the acquisition module 4 collects the fiber fracture acoustic signal through the pickup array, and the analysis system 5 forms a signal waveform through the received fiber fracture acoustic signal, and displays the signal waveform on the computer. When the fiber breaks, the signal waveform has obvious peaks and troughs. By analyzing and calculating the characteristics of the signal waveform of the fiber fracture acoustic signal collected by each pickup, the internal force, damage, and fracture of the bundle fiber during the stretching process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com