Method for Coating Antigen/Antibody on Microwell Plate Using Flat-bed Inkjet Printer

An inkjet printer and antigen-coated technology, which is used in replication/marking methods, printing, instruments, etc., can solve the problems of inaccurate manual sample addition, error-prone operation, high price, etc., and achieve convenient qualitative analysis and quantitative detection. , high accuracy and precision, the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment is realized after refitting the Epson L805 inkjet printer. The base of the original printer is disassembled, a mobile working platform is added, and the paper pick-up motor of the printer is used to drive the movement of the working platform to convert it into a flatbed printer. The printer holds six color ink cartridges, light magenta, light cyan, yellow, magenta, cyan, black, so multiple reagents can be added at the same time.

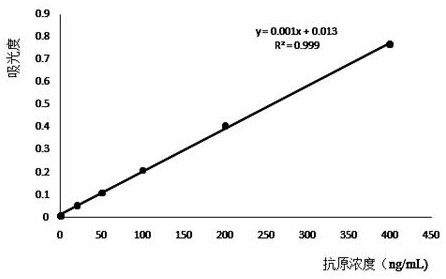

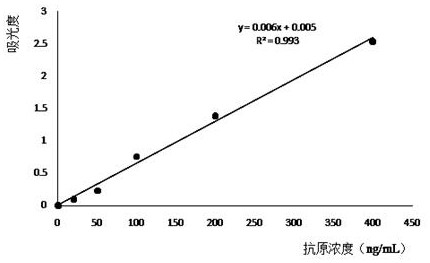

[0032] In this example, a flat-panel inkjet printer was used to coat the anti-AFP antibody on a 96-well plate. In order to save reagents and avoid inaccurate operation results caused by spraying reagents onto the walls of the wells because the holes of the standard microplate plate were too deep, this paper The embodiment is completed with a commercially purchased 96-well plate cover, which greatly reduces the amount of reagents added (100 μL / well is required for traditional ELISA coating, and only 3-10 μL is required for inkjet...

Embodiment 2

[0040] In this embodiment, add the washing liquid to the clean ink cartridge corresponding to "yellow" and then put the ink cartridge into the correct position of the printer, set the corresponding position of the micropores that need to be washed to "yellow" in the image and save it as file 3. To implement Li No. 1 Middle School 4 o After overnight C, place the microwell plate back on the printer workbench and print file 3. It can be printed several times in a row so that the amount of washing liquid added exceeds the amount of coating liquid, so as to thoroughly clean the micropores. In subsequent washing operations is also like this. After printing, shake the microplate slightly, pour off the washing solution, pat it dry, and then place the microplate on the printer workbench. In Example 1, the microwell plate after adding the blocking solution at room temperature for two hours was washed in the same way to obtain a fully coated 96-well plate.

Embodiment 3

[0042] When two or more antibodies / antigens need to be coated, if anti-AFP antibody is coated in a part of wells of the same microwell plate, and AFP antigen is coated in another part of wells, anti-AFP antibody can be added Add the AFP antigen to the clean ink cartridge corresponding to "magenta", and place the ink cartridge in the correct position of the printer, and set the corresponding position of the microwell that needs to add anti-AFP antibody in the image to " Magenta", set the microwells that need to add AFP antigen to "black" in the corresponding position in the image and save it as file 4, print file 4 to add anti-AFP antibody and AFP antigen in different microwells at the same time. It is also possible to set the colors corresponding to the image corresponding to the anti-AFP antibody and the image corresponding to the AFP antigen respectively, save and print separately, that is, add different reagents to different microwells successively. When there are more than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com