Method for manufacturing furniture using polymer extrusion profiles

A technology of extruded profiles and polymers, which is applied in household appliances, furniture parts, furniture connections, etc., to achieve the effects of easy assembly, protection of natural resources, and increased transportation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

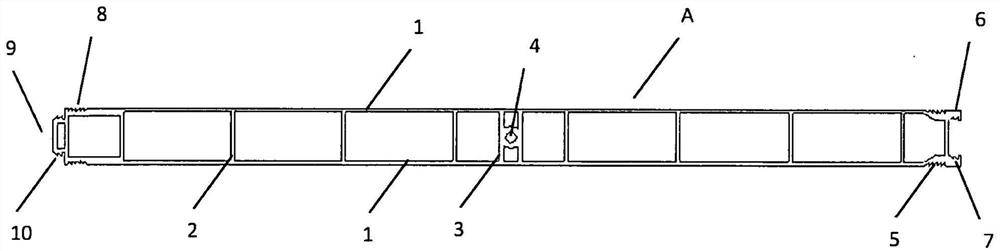

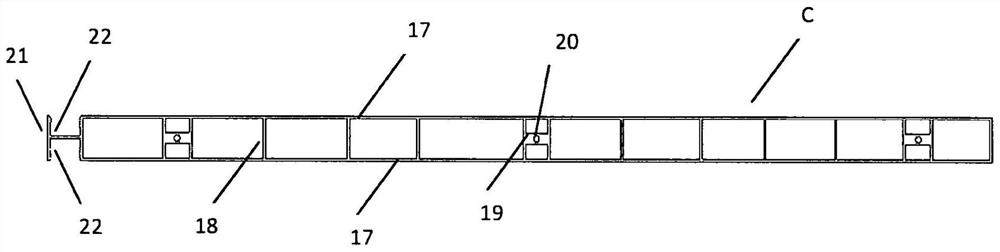

[0032] according to Figures 1 to 10 , the proposed furniture manufacturing method consists of extruding profiles using three pieces of honeycomb polymer, the first profile A is formed by a thin elongated shape, which is provided with a first outer wall 1 supported by a first inner structural wall 2, showing In the center the first support 3 can receive a screw through a first hole 4 . The lateral end of the first profile A has a first outer flexible flap 5 on one side, a flange 6 provided with a first inner flexible flap 7 . The opposite side has an opposite side outer flexible flap 8 and a fitting 9 provided with a further outer flexible flap 10 .

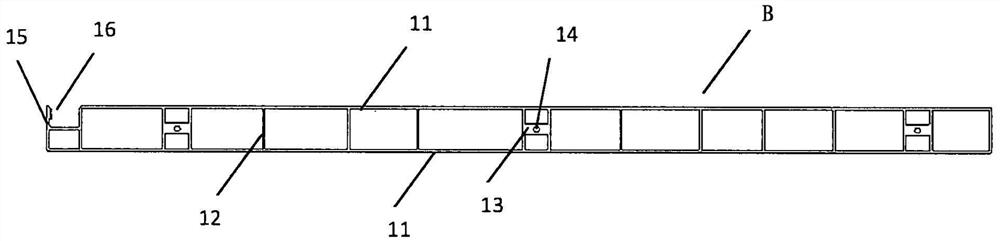

[0033] The second profile B is formed of a thin elongated shape provided with a second outer wall 11 supported by a second inner structural wall 12 showing in the center a second support 13 capable of receiving a screw through a second hole 14 . The side end of the second profile B shows an angled structure 15 internally provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com