Two-dimensional layered Ti3C2 film and preparation method and application thereof

A two-dimensional layered and embedded technology, which is applied in the direction of chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as unusable sieving, and achieve the effects of good mechanical properties, good stability, and high application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

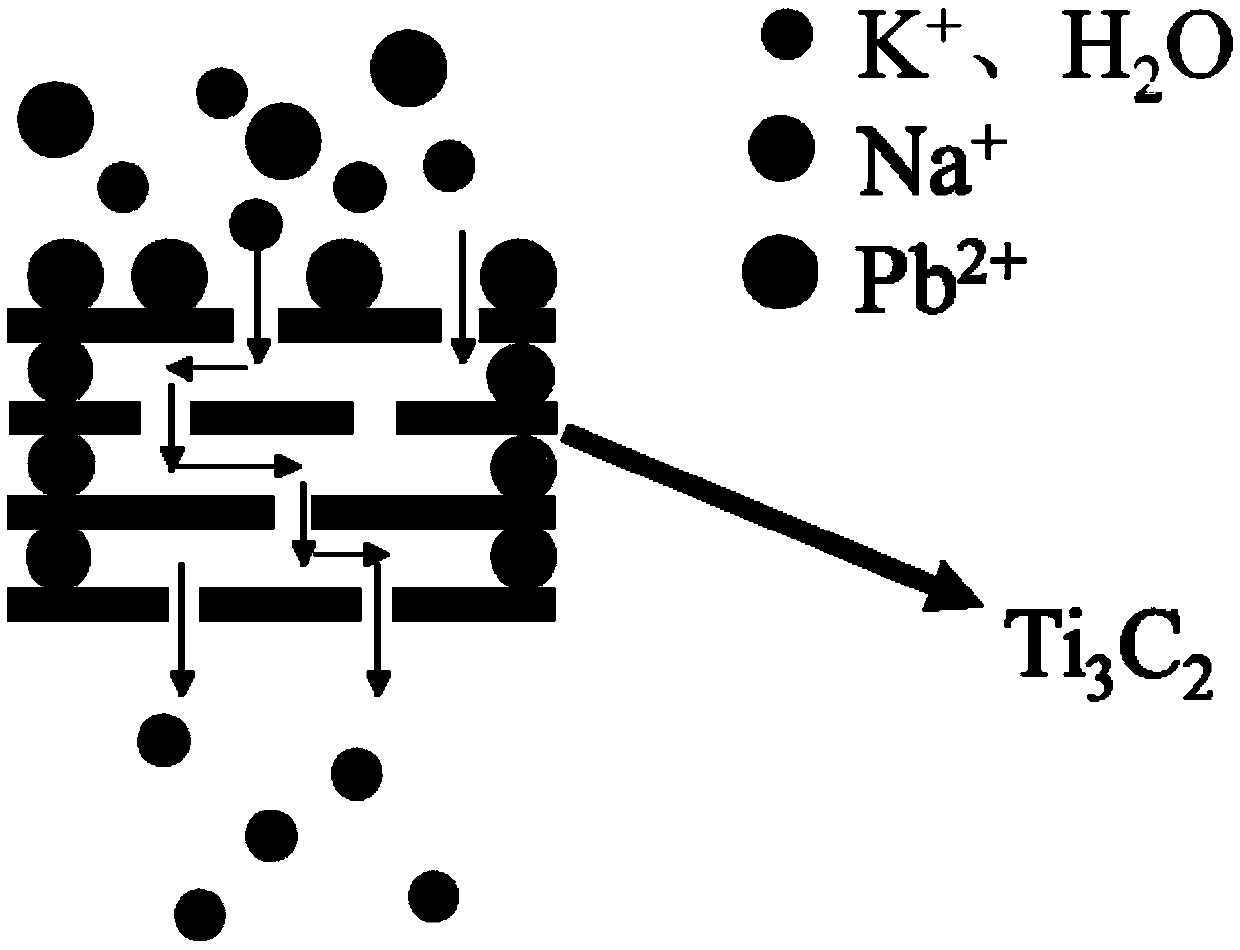

[0037] (1) Under the condition of magnetic stirring, take 8g Ti 3 AlC 2 Slowly add 80ml of HF (40wt.%) solution, react at 50°C for 24h, take it out, and use deionized water to wash centrifugally (5000rpm / min, 10min) until the supernatant pH ≈ 6, and keep the lower layer of solid to obtain Ti 3 C 2 ;

[0038] (2) Take 1g Ti 3 C 2 Mix it with 20ml NaOH solution (5wt.%), stir it magnetically for 12h, take it out, wash it by centrifugation (5000rpm / min, 10min), and wash it 5 times to get the intercalated Ti 3 C 2 ;

[0039] (3) Inlay Ti 3 C 2 Add it into 100ml deionized water, sonicate for 30min (ultrasonic power is 300w), and then centrifuge (5000rpm / min, 30min) to obtain Ti 3 C 2 Colloidal solution;

[0040] (4) Under vacuum assistance, the Ti 3 C 2 The colloidal solution was deposited on a mixed cellulose ester microporous filter membrane, and dried naturally at room temperature for 5 min to obtain a two-dimensional layered Na-Ti 3 C 2 membrane.

[0041] Two-dim...

Embodiment 2

[0043] (1) Under the condition of magnetic stirring, take 8g Ti 3 AlC 2 Slowly add 100ml HF (40wt.%) solution, react at 50°C for 24h, take it out, and use deionized water to wash centrifugally (5000rpm / min, 10min) until the supernatant pH ≈ 6, and keep the lower layer solid to obtain Ti 3 C 2 ;

[0044] (2) Take 1g Ti 3 C 2 Mix with 30ml NaOH solution (5wt.%), stir magnetically for 24h, take it out, wash by centrifugation (5000rpm / min, 10min), and wash 5 times to obtain intercalated Ti 3 C 2 ;

[0045] (3) Inlay Ti 3 C 2 Add it into 100ml deionized water, sonicate for 60min (ultrasonic power is 300w), and then centrifuge (5000rpm / min, 35min) to obtain Ti 3 C 2 Colloidal solution;

[0046] (4) Under vacuum assistance, the Ti 3 C 2 The colloidal solution was deposited on a mixed cellulose ester microporous filter membrane, and dried naturally at room temperature for 5 min to obtain a two-dimensional layered Na-Ti 3 C 2 membrane.

Embodiment 3

[0048] (1) Under the condition of magnetic stirring, take 8g Ti 3 AlC 2 Slowly add 100ml HF (40wt.%) solution, react at 50°C for 30h, take it out, and use deionized water to wash centrifugally (5000rpm / min, 10min) until the supernatant pH ≈ 6, and keep the lower layer solid to obtain Ti 3 C 2 ;

[0049] (2) Take 1g Ti 3 C 2 Mix with 20ml NaOH solution (5wt.%), stir magnetically for 24h, take it out, wash by centrifugation (5000rpm / min, 10min), and wash 5 times to obtain intercalated Ti 3 C 2 ;

[0050] (3) Inlay Ti 3 C 2 Add it into 150ml deionized water, ultrasonicate for 60min (ultrasonic power is 300w), and then centrifuge (5000rpm / min, 40min) to obtain Ti 3 C 2 Colloidal solution;

[0051] (4) Under vacuum assistance, the Ti 3 C 2 The colloidal solution was deposited on a mixed cellulose ester microporous filter membrane, and dried naturally at room temperature for 5 min to obtain a two-dimensional layered Na-Ti 3 C 2 membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com