Composite material pultrusion die, equipment and method, profile and application

A composite material and pultrusion die technology, which is applied in the field of forming equipment and composite material pultrusion die, can solve the problems of too many mold fastening screws, large contact surface of profiles, and large internal stress of profiles, etc., to achieve short manufacturing cycle and high surface quality Good, uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

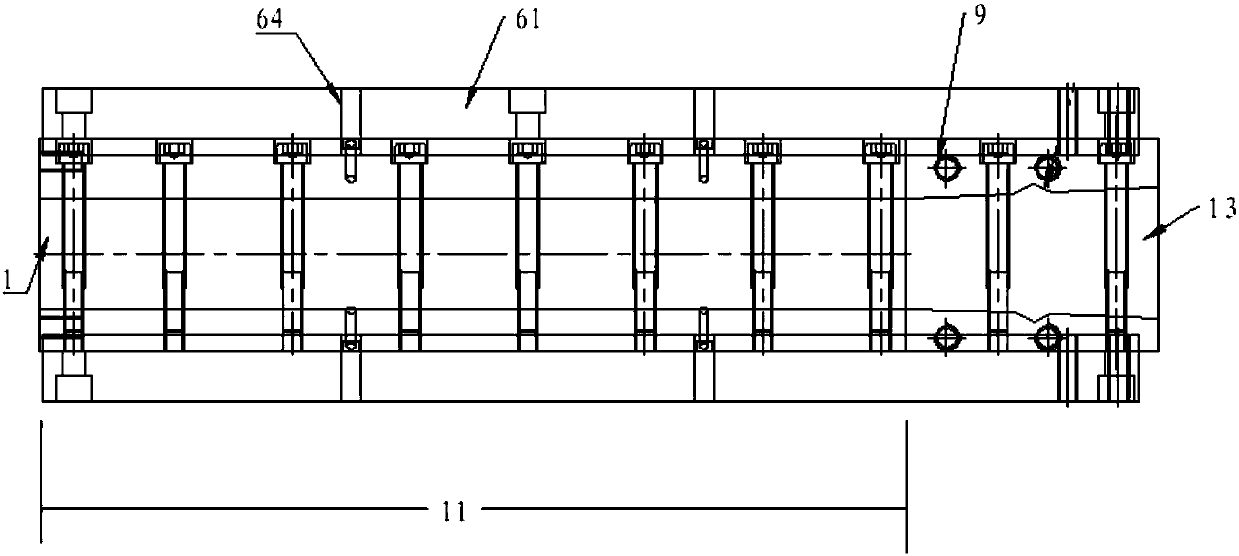

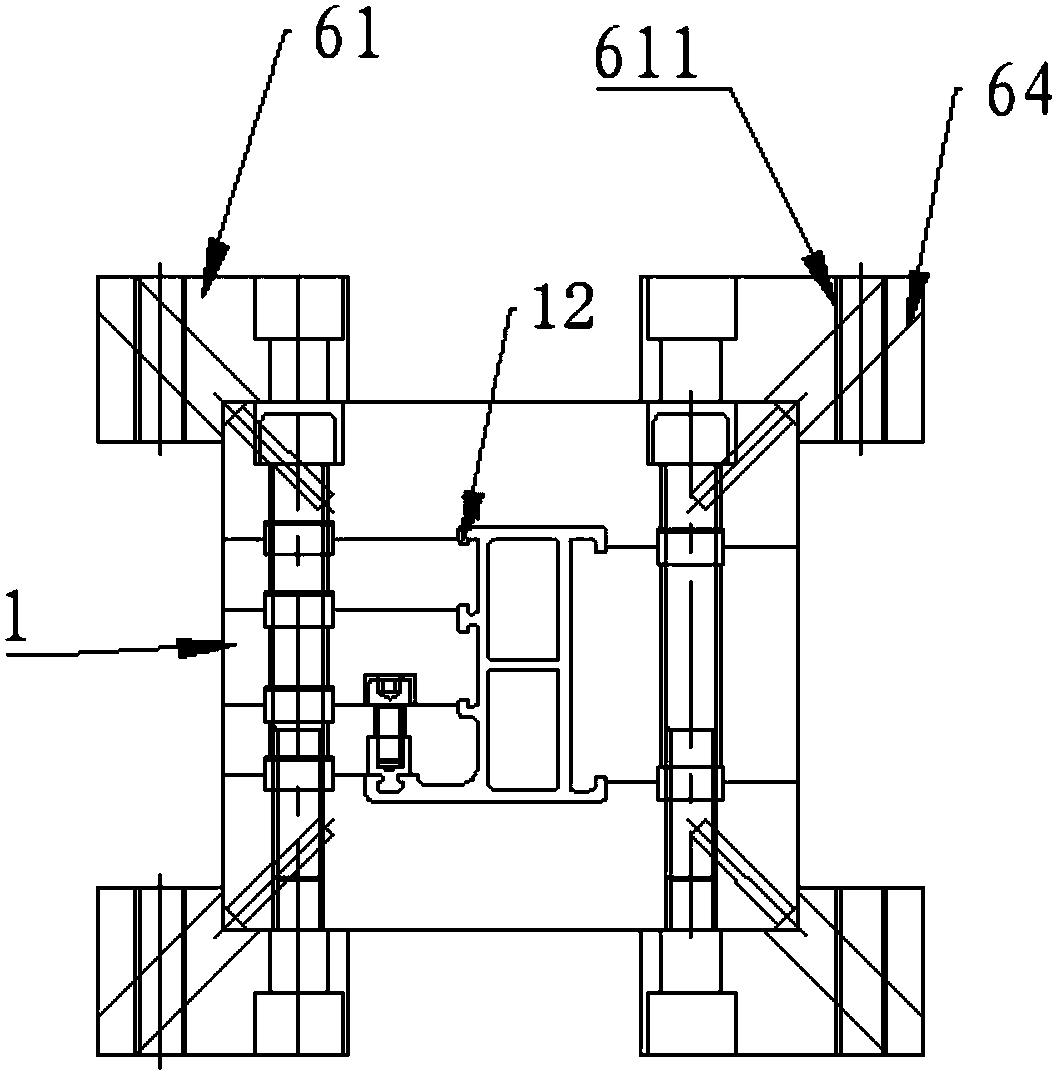

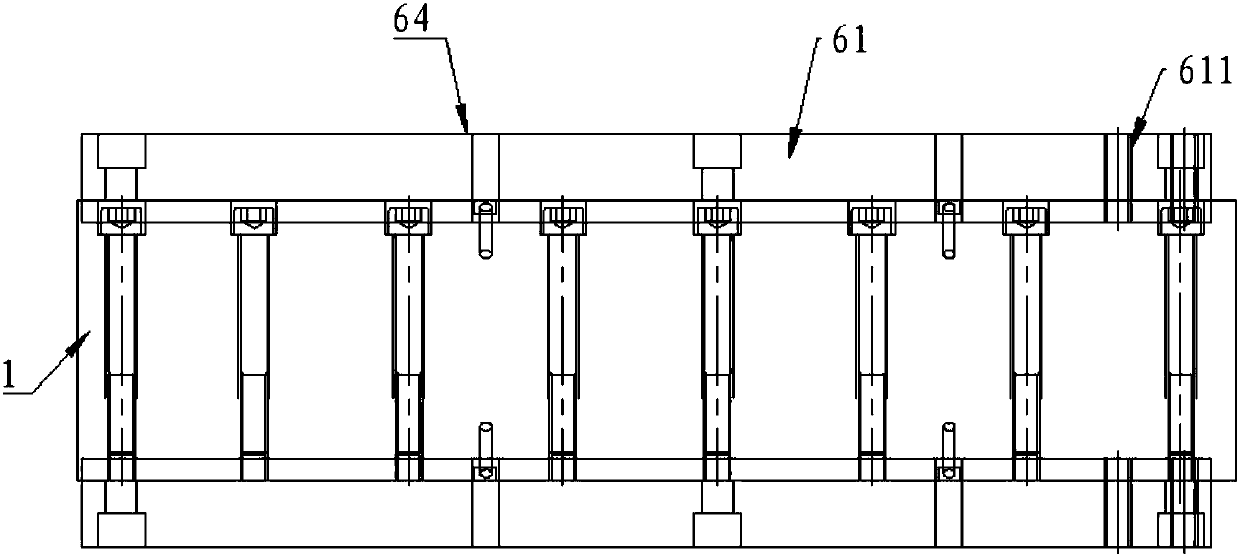

[0087] In order to achieve the purpose of the present invention, in some embodiments of the composite material pultrusion die, molding equipment and its method, profiles and applications thereof, such as figure 1 and 2 As shown, the composite material pultrusion die 1 includes: a mold body 11, the mold body 11 contains a molding section and the molding section is a cavity with a constant cross section, and the length of the molding section is ≤ 700 mm.

[0088] The length of the molding section of the mold body 11 of the present invention is ≤700 mm, the contact surface with the profile is small, and the resistance to the profile is small, resulting in a small pultrusion force during the molding process, and small internal stress in the profile, so that the profile has good straightness and uniform wall thickness. , The surface quality is go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com