Method for producing ethylene from aromatic hydrocarbon raffinate

A technology for raffinating oil and aromatics, applied in chemical instruments and methods, hydrocarbon cracking to produce hydrocarbons, organic chemistry, etc., can solve problems such as slowing down the coking rate of cracking furnace tubes, shortening the operating cycle of the device, and substandard product quality, etc., to achieve It is conducive to long-term stable operation, low maintenance cost, and slow down the effect of coking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

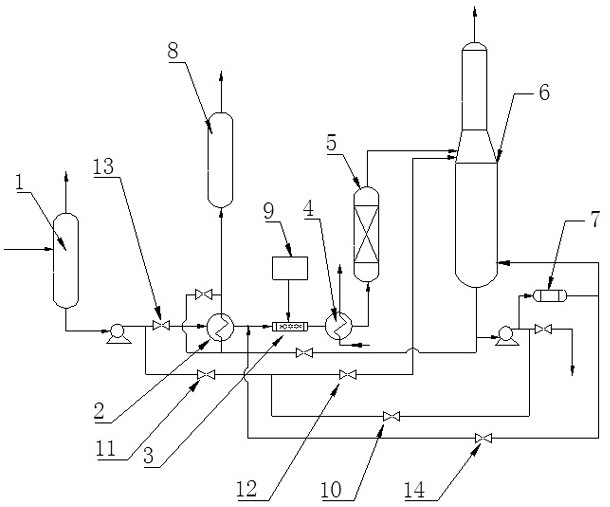

[0049] according to figure 1 New installation shown. Aromatic hydrocarbon raffinate oil is fully mixed and dissolved in the SX static mixer through the feed pump, the first heat exchanger 2 and hydrogen, and then heat-exchanged by the second heat exchanger 4, and enters from the bottom of the hydrogenation reactor 5 , contact with the hydrorefining catalyst, carry out hydrogenation reaction under the condition of hydrogenation reaction, make the olefins in the aromatic hydrocarbon raffinate saturated, and the aromatic hydrocarbon raffinate oil is in liquid state. After the reaction, the hydrogenation reaction effluent enters the stabilization tower 6 for gas-liquid separation, and light hydrocarbons below C5 are obtained at the top of the tower, while the bottom material is passed into the ethylene cracking device 8 for cracking. The content of olefins in the aromatics raffinate before and after the hydrogenation reaction is listed in Table 2.

[0050] Adopt the method of th...

Embodiment 2

[0054] according to figure 1 New installation shown. Aromatic hydrocarbon raffinate oil is fully mixed and dissolved in the SX static mixer through the feed pump, the first heat exchanger 2 and hydrogen, and then heat-exchanged by the second heat exchanger 4, and enters from the bottom of the hydrogenation reactor 5 , contact with the hydrorefining catalyst, carry out hydrogenation reaction under the condition of hydrogenation reaction, make the olefins in the aromatic hydrocarbon raffinate saturated, and the aromatic hydrocarbon raffinate oil is in liquid state. After the reaction, the hydrogenation reaction effluent enters the stabilization tower 6 for gas-liquid separation, and light hydrocarbons below C5 are obtained at the top of the tower, while the bottom material is passed into the ethylene cracking device 8 for cracking. The content of olefins in the aromatics raffinate before and after the hydrogenation reaction is listed in Table 2.

[0055] Adopt the method of th...

Embodiment 3

[0066] During the test operation, open the second valve 11 and the third valve 12 on the cross-line, and keep the second valve 11 and the third valve 12 at a small opening to simulate the internal leakage of the valve. (the first valve 10 is not opened), the olefin content in the hydrogenation reaction effluent is greater than 0.5wt%, and after the leak-proof pipeline is enabled (the first valve 10 is opened), the olefin content of the hydrogenation reaction effluent is stable, as low as 0.1wt%.

[0067]After calculation, under certain working conditions, when the catalyst performance is good (the product index is far lower than the control index), if there is 10% internal leakage, the olefin content in the hydrogenation reaction effluent is greater than 0.5wt%; when the catalyst is used In the later stage (the olefin content in the hydrogenation reaction effluent is close to 0.5wt%), if there is a slight internal leakage, it will be higher than 0.5wt%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap