A kind of high glow wire halogen-free flame retardant polyamide compound and its preparation method and application

A flame retardant polyamide, high glow wire technology, applied in the field of halogen-free flame retardant polyamide compounds and moldings containing halogen-free flame retardant polyamide compounds, can solve problems such as unmentioned polyamide glow wire properties , to achieve the effect of good environmental friendliness, high glow wire performance, good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

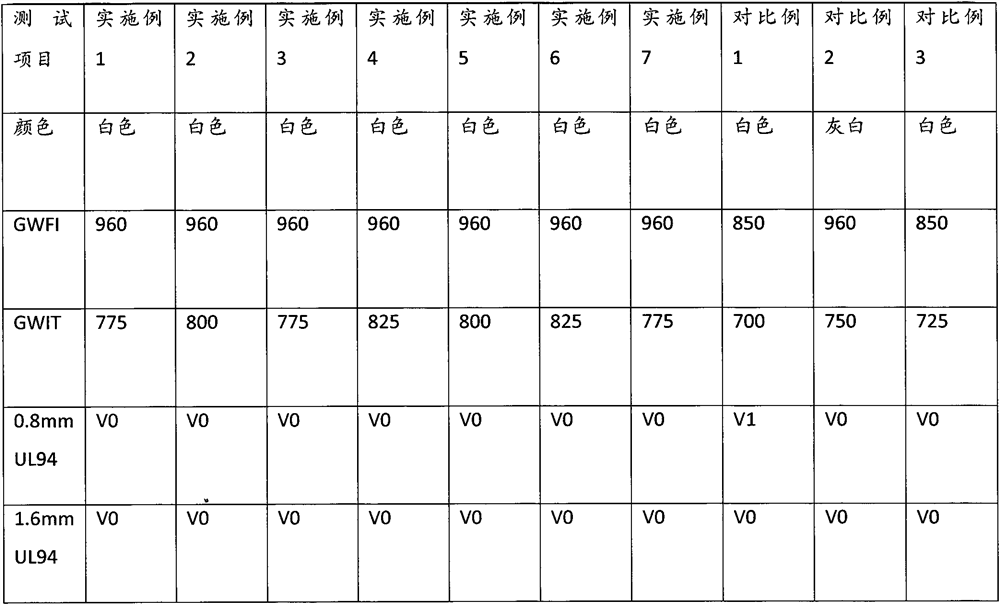

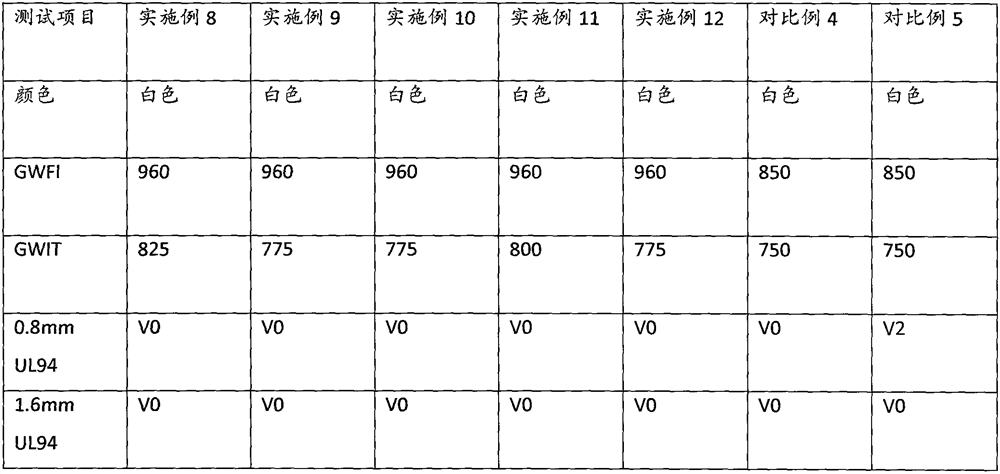

Examples

Embodiment 1

[0027] A high glow wire halogen-free flame retardant polyamide compound, comprising the following components by weight percentage:

[0028] Polyamide 66 49.6%, glass fiber 30%, aluminum diethylphosphinate 14%, polyaryl phosphate 3%, melamine polyphosphate 3%, antioxidant 1098 0.2%, lubricant PETS 0.2%.

[0029] The mixture was formed by twin-screw granulation and then tested.

Embodiment 2

[0031] A high glow wire halogen-free flame retardant polyamide compound, comprising the following components by weight percentage:

[0032] Polyamide 66 49.6%, glass fiber 30%, aluminum diethylphosphinate 12%, polyaryl phosphate 5%, melamine polyphosphate 3%, antioxidant 1098 0.2%, lubricant PETS 0.2%.

[0033] The mixture was formed by twin-screw granulation and then tested.

Embodiment 3

[0035] A high glow wire halogen-free flame retardant polyamide compound, comprising the following components by weight percentage:

[0036] Polyamide 66 49.6%, glass fiber 30%, aluminum diethylphosphinate 14%, polyaryl phosphate 1%, melamine polyphosphate 5%, antioxidant 1098 0.2%, lubricant PETS 0.2%.

[0037] The mixture was formed by twin-screw granulation and then tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com