Foamed refractory coating

A refractory coating and foaming technology, applied in the field of foaming refractory coatings, can solve the problems of insufficient coating operability, easy cracking, hard foaming layer, etc., and achieve good coating operability, suppress temperature rise, and suppress deformation and collapse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~3

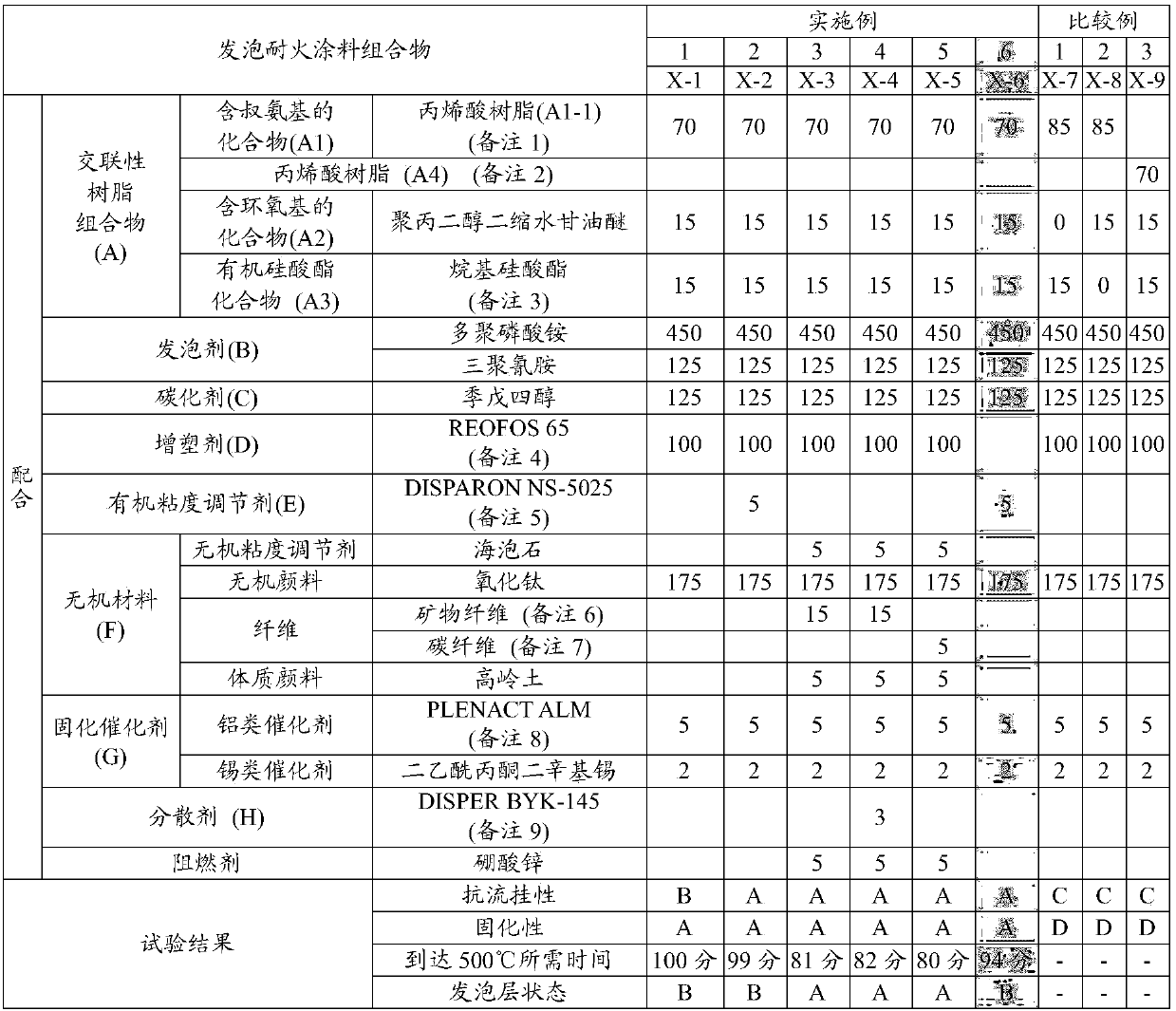

[0186] Each component was blended according to the composition shown in the following table, and it stirred and mixed it uniformly using the planetary mixer, and produced foaming refractory coating composition (X-1)-(X-9). In addition, the numerical value in a table shows a non-volatile component.

[0187] Table 1

[0188]

[0189] (Remark 1) Acrylic resin (A1-1): Isobutyl methacrylate / n-butyl methacrylate / n-butyl acrylate / N,N-dimethylaminoethyl methacrylate / hydroxyethyl acrylate (mass ratio)=45 / 13 / 29 / 10 / 3 interpolymer, amine equivalent 3100, weight average molecular weight 35000;

[0190] (Remark 2) Acrylic resin (A4): isobutyl methacrylate / n-butyl methacrylate / n-butyl acrylate / hydroxyethyl acrylate (mass ratio)=45 / 23 / 29 / 3 copolymer, weight average Molecular weight 35000;

[0191] (Remark 3) Alkyl silicate: a low condensation product of tetramethoxysilane, the average number of Si is 4, and the number average molecular weight is 470;

[0192] (Remark 4) REOFOS65: trade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com