Aqueous coating composition and method for producing aqueous coating composition

A technology of water-based coatings and compositions, applied in polyester coatings, polyurea/polyurethane coatings, devices for coating liquids on surfaces, etc., can solve problems such as poor appearance of coating films, and achieve good coating workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

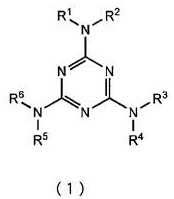

[0084] As a preferred mode of preparing the core part, for example, the following mode can be cited: the core part preparation monomer (a-1) contains a hydroxyl group-containing polymerizable monomer and an acid anhydride group-containing polymerizable monomer, and in the core part In the preparation of the monomer (a-1), after polymerizing monomers other than the acid anhydride group-containing polymerizable monomer, the hydroxyl group of the obtained polymer is reacted with the acid anhydride group of the acid anhydride group-containing polymerizable monomer, and the A polymerizable group is introduced into a polymer. Thereby, there is an advantage that a polymerizable group forming a graft portion at the time of shell polymerization can be introduced into the core portion.

[0085] Next, the shell portion preparation monomer (a-2) containing an acid group-containing polymerizable monomer is solution-polymerized in the presence of the core portion obtained above, thereby for...

manufacture example 1

[0175] Production example 1 Production of acrylic resin dispersion (1)

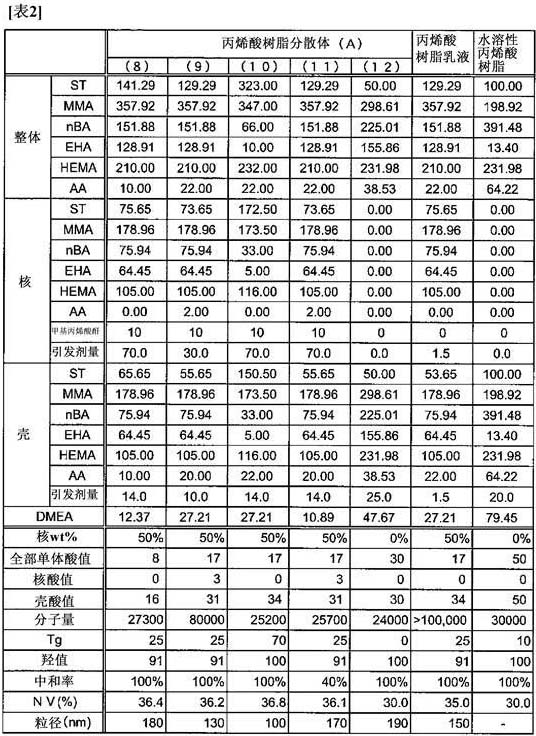

[0176] Preparation process 1

[0177] 210 mass parts of butyl acetates were put into the reactor equipped with a stirring, cooling, and heating apparatus, and it heated to 120 degreeC. Then, 73.65 parts by mass of styrene (ST), 178.96 parts by mass of methyl methacrylate (MMA), 75.94 parts by mass of n-butyl acrylate (BA), 64.45 parts by mass of 2-ethylhexyl acrylate, For a monomer mixture of 105.00 parts by mass of ethyl ester (HEMA), 2.0 parts by mass of acrylic acid (AA), and 70 parts by mass of tert-butyl peroxy-2-ethylhexanoate dissolved in 45 parts by mass of butyl acetate 90 minutes to 2 systems isochronous dropwise. 10 parts by mass of methacrylic anhydride was added while maintaining the reaction container at 120° C., and maintained for 2 hours. Then, it cooled to 60 degreeC, and obtained the core polymer (core part).

[0178] Preparation process 2

[0179]Next, 210 mass parts of butyl...

manufacture example 2~11(6~11

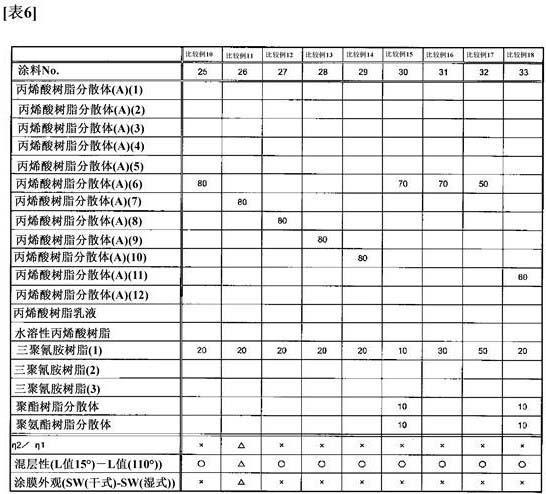

[0186] Production examples 2 to 11 (6 to 11 are comparative production examples) Production of acrylic resin dispersion (A) (2) to (11)

[0187] Except having changed the charging amount of each raw material into the value described in Table 1, it carried out similarly to Example 1, and produced the acrylic resin dispersion (A)(2)-(11).

[0188] Production Example 12 (Comparative Production Example) Production of a single-layer acrylic resin dispersion (12)

[0189] 466 parts by mass of butyl acetate was placed in a reactor equipped with a cooling and heating device, and heated to 120°C. Then, 50.00 parts by mass of styrene (ST), 298.61 parts by mass of methyl methacrylate (MMA), 225.01 parts by mass of n-butyl acrylate (BA), and 155.86 parts by mass of 2-ethylhexyl acrylate (2-EHA) , a monomer mixture of 231.98 parts by mass of hydroxyethyl methacrylate (HEMA), 38.53 parts by mass of acrylic acid (AA), and 15 parts by mass of tert-butyl peroxy-2-ethylhexanoate dissolved ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com